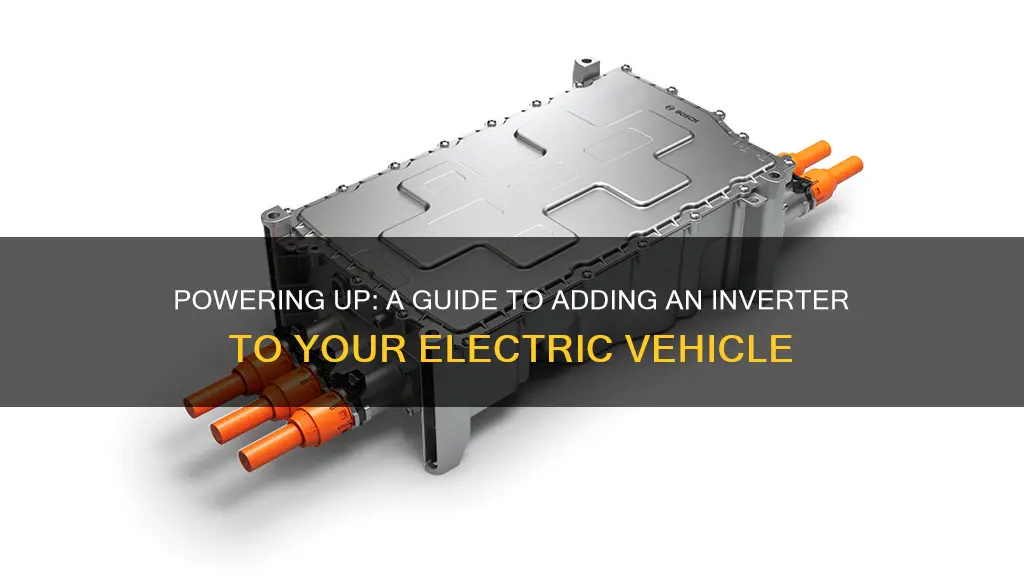

Adding an inverter to an electric vehicle (EV) is a crucial step for those looking to enhance their vehicle's performance and capabilities. This process involves integrating an inverter, a device that converts direct current (DC) from the EV's battery into alternating current (AC) for various electrical systems. By adding an inverter, EV owners can power additional accessories, such as air conditioning, heating, or even a backup generator, which can significantly improve the vehicle's functionality and comfort. This guide will provide a comprehensive overview of the steps involved in adding an inverter to an electric vehicle, ensuring a smooth and efficient installation process.

What You'll Learn

- Battery Compatibility: Ensure the inverter is compatible with your EV's battery type and voltage

- Wiring and Connections: Carefully connect the inverter to the EV's electrical system, following manufacturer instructions

- Charging Systems: Integrate the inverter with your EV's charging system for efficient power management

- Safety Measures: Implement safety protocols to prevent electrical hazards during inverter installation

- Performance Optimization: Calibrate the inverter for optimal performance and efficiency with your EV

Battery Compatibility: Ensure the inverter is compatible with your EV's battery type and voltage

When considering the installation of an inverter with your electric vehicle (EV), one of the most critical aspects to focus on is battery compatibility. This is because the inverter's role is to convert the direct current (DC) electricity stored in your EV's battery into alternating current (AC) electricity that can power your home or other devices. Therefore, it is essential to ensure that the inverter you choose is compatible with your EV's battery type and voltage to ensure optimal performance and safety.

The first step in determining compatibility is to identify the type of battery in your EV. Most modern EVs use lithium-ion batteries, which are known for their high energy density and long lifespan. However, some older models or specific vehicle types might have different battery chemistries, such as nickel-metal hydride (NiMH) or lead-acid batteries. It is crucial to check your vehicle's manual or consult with the manufacturer to confirm the battery type and its specifications.

In addition to the battery type, you need to consider the voltage of your EV's battery. Lithium-ion batteries typically operate at voltages ranging from 300V to 400V, while some older models might have lower or higher voltage ranges. The inverter must be designed to handle the specific voltage of your EV's battery to ensure efficient power conversion without any risk of damage or malfunction.

To ensure compatibility, you should look for inverters that are specifically designed for your EV's battery type and voltage. Many manufacturers offer inverters tailored to their specific vehicle models, ensuring a perfect match in terms of voltage and battery chemistry. These dedicated inverters often provide better efficiency, reliability, and safety compared to generic models. When purchasing or installing an inverter, always refer to the manufacturer's guidelines and recommendations to ensure you select the right product for your EV.

In summary, battery compatibility is a critical factor when adding an inverter to your electric vehicle. By understanding your EV's battery type and voltage, you can choose an inverter that will work seamlessly with your vehicle's power system. Always consult the manufacturer's specifications and guidelines to ensure a safe and efficient installation.

Exploring the Range of Electric Conveyance Vehicle Sizes

You may want to see also

Wiring and Connections: Carefully connect the inverter to the EV's electrical system, following manufacturer instructions

When integrating an inverter into an electric vehicle (EV) system, wiring and connections are critical to ensure safe and efficient operation. Here's a detailed guide on this process:

Understanding the Inverter and EV System: Before beginning, thoroughly understand the inverter's specifications and the EV's electrical architecture. Inverters convert direct current (DC) from the EV's battery to alternating current (AC) for household appliances and other AC-powered devices. Familiarize yourself with the inverter's input and output connections, voltage requirements, and power ratings. Similarly, study the EV's electrical system, including the battery, alternator (if equipped), DC-DC converter, and any existing AC power outlets or accessories.

Safety First: Working on electrical systems can be hazardous. Always prioritize safety by wearing appropriate personal protective equipment (PPE), such as insulated gloves and safety goggles. Ensure the EV is parked on a level surface, and engage the parking brake for added security. If you're unsure about any aspect of the installation, consult a professional mechanic or electrician experienced in EV conversions.

Wiring the Inverter:

- Power Supply: Connect the inverter's input terminals to the EV's battery. This typically involves attaching positive and negative leads to the corresponding battery terminals. Ensure a secure connection using appropriate-sized wires and terminals to handle the inverter's power output.

- Grounding: Proper grounding is essential for safety and performance. Connect the inverter's ground terminal to a reliable ground point on the EV's chassis or frame. This helps dissipate electrical faults and ensures the inverter's electrical system is properly bonded.

- Output Connections: Route the inverter's output wires to the desired locations for powering appliances or accessories. This may involve running wires through the EV's interior or along the vehicle's exterior. Secure the wires using suitable insulation and protective sleeves to prevent damage from heat, vibration, or moisture.

Following Manufacturer Instructions:

- Every inverter and EV model is unique, so it's crucial to refer to the manufacturer's instructions provided with your inverter and EV documentation. These instructions will provide specific wiring diagrams, connection points, and safety guidelines tailored to your particular setup.

- Pay close attention to the recommended wire sizes, fuse ratings, and grounding techniques. Adhering to these specifications ensures compatibility, safety, and optimal performance.

- If you encounter any complex wiring scenarios or need to modify the EV's electrical system, consult the manufacturer's technical support or seek professional assistance.

Testing and Verification: After completing the wiring, thoroughly test the inverter's functionality. Start the EV, engage the inverter, and check for proper power output to connected devices. Verify that all connections are secure and that there are no electrical faults. Regularly inspect the wiring for any signs of damage or wear, especially in areas prone to vibration or moisture.

Remember, proper wiring and connections are fundamental to a successful EV inverter installation. Always prioritize safety, follow manufacturer guidelines, and seek professional help when needed to ensure a reliable and efficient system.

Understanding Dashes: Decoding Vehicle Electrical Schematics

You may want to see also

Charging Systems: Integrate the inverter with your EV's charging system for efficient power management

When integrating an inverter with your electric vehicle's (EV) charging system, efficient power management is key to optimizing performance and ensuring a seamless experience. Here's a detailed guide on how to achieve this:

Understanding the Components: Begin by familiarizing yourself with the key components involved. Your EV's charging system typically includes a battery, a charger, and a power inverter. The inverter plays a crucial role in converting the direct current (DC) from the battery to alternating current (AC) for household use or other applications. Understanding the specifications and capabilities of each component is essential for successful integration.

Inverter Selection: Choose an inverter that is compatible with your EV's charging system and meets your power requirements. Consider factors such as voltage, current capacity, and frequency. Ensure the inverter can handle the maximum charging current your EV can accept. For instance, if your EV supports fast charging, select an inverter with a higher power rating to accommodate the increased current.

Wiring and Connections: Proper wiring is critical to efficient power management. Connect the inverter to the EV's battery using appropriate gauge cables to handle the expected current flow. Ensure all connections are secure and follow the manufacturer's guidelines for wiring. Consider using a dedicated circuit for charging to minimize power losses and ensure a stable power supply.

Charging System Integration: Integrate the inverter with your EV's charging system by connecting it in parallel or series, depending on your specific setup and requirements. Parallel integration allows for higher current handling, while series integration can be useful for voltage regulation. Consult the inverter and EV manufacturer's instructions for the correct configuration.

Efficient Power Distribution: Efficient power management involves optimizing the distribution of electricity. Utilize smart charging techniques, such as load balancing, to ensure that the inverter and EV battery are charged efficiently. This can involve programming the inverter to adjust charging rates based on grid conditions or using advanced charging systems that communicate with the EV to optimize charging times.

Safety Considerations: Prioritize safety during the integration process. Ensure that the inverter and charging system comply with relevant safety standards and regulations. Implement overcurrent and overvoltage protection mechanisms to safeguard against electrical hazards. Regularly inspect and maintain the system to identify and address any potential issues.

By carefully integrating the inverter with your EV's charging system, you can achieve efficient power management, ensuring your electric vehicle is charged optimally while maintaining a safe and reliable operation. This approach maximizes the performance and longevity of your EV's battery and overall charging infrastructure.

Electric Vehicles: Powering the Future, One Charge at a Time

You may want to see also

Safety Measures: Implement safety protocols to prevent electrical hazards during inverter installation

When installing an inverter for an electric vehicle, prioritizing safety is paramount to prevent electrical hazards. Here are some essential safety measures to follow:

- Electrical Knowledge and Training: Ensure that all personnel involved in the installation process have a comprehensive understanding of electrical systems and inverter technology. Provide thorough training on safety protocols, including identifying potential hazards, understanding voltage levels, and recognizing the proper use of tools and equipment. This knowledge will enable them to handle the installation with precision and caution.

- Power Source Isolation: Before beginning the installation, isolate the power source to the electric vehicle's battery. This step is critical to prevent accidental activation of the vehicle's systems during the installation process. Use appropriate tools, such as circuit breakers or fuses, to disconnect the power supply temporarily. Verify the disconnection by using a voltage tester to ensure no live current is present.

- Grounding and Bonding: Establish a proper grounding system to minimize the risk of electric shock. Connect the inverter's grounding terminal to a reliable ground point, such as a metal frame or a dedicated grounding rod. Ensure all tools and equipment used during the installation are properly grounded to provide an additional layer of safety.

- Personal Protective Equipment (PPE): Mandate the use of appropriate PPE to protect against electrical hazards. This includes insulated gloves, safety goggles, and non-conductive footwear. PPE should be worn throughout the installation process to safeguard against accidental contact with live electrical components.

- Follow Manufacturer's Guidelines: Adhere strictly to the inverter manufacturer's instructions and guidelines. Each inverter model may have specific safety requirements and procedures. Refer to the user manual for detailed information on installation, wiring, and any unique safety considerations related to your inverter model.

- Regular Maintenance and Inspections: Implement a maintenance schedule for the inverter system to ensure its longevity and safety. Regularly inspect the inverter, cables, and connections for any signs of damage, corrosion, or wear. Address any issues promptly to prevent potential electrical hazards over time.

By following these safety measures, you can significantly reduce the risk of electrical accidents during the installation of an inverter for an electric vehicle, ensuring a secure and efficient power conversion system.

Efficiently Peel Off Your EV Sticker: A Step-by-Step Guide

You may want to see also

Performance Optimization: Calibrate the inverter for optimal performance and efficiency with your EV

When integrating an inverter with an electric vehicle (EV), calibration is a critical step to ensure optimal performance and efficiency. The inverter acts as a bridge between the battery and the electric motor, converting direct current (DC) from the battery to alternating current (AC) that the motor can use. Proper calibration ensures that the inverter operates at its peak, maximizing the vehicle's range and overall performance.

The calibration process involves adjusting various parameters within the inverter's control system. These parameters include voltage, frequency, and power factors, which need to be fine-tuned to match the specific requirements of the EV's battery and motor. By optimizing these settings, you can achieve a more efficient power transfer, reducing energy losses and improving the vehicle's overall efficiency.

One key aspect of calibration is setting the appropriate voltage levels. The inverter must be configured to match the DC voltage of the battery pack. This ensures that the inverter can efficiently convert the DC power to AC for the motor. Incorrect voltage settings can lead to reduced performance and even damage to the inverter or motor over time.

Frequency calibration is another important parameter. The inverter needs to be set to the correct frequency to match the motor's requirements. Electric motors operate at specific frequencies, and the inverter must provide the necessary frequency to ensure smooth and efficient operation. Adjusting the frequency can significantly impact the motor's performance and efficiency.

Additionally, power factor calibration is crucial. This setting determines how effectively the inverter converts power. A well-calibrated power factor ensures that the inverter operates within an optimal range, minimizing losses and maximizing efficiency. It's essential to consider the EV's specific power requirements and adjust the power factor accordingly.

To perform the calibration, you can typically access the inverter's control panel or use software tools provided by the manufacturer. These tools allow you to adjust the parameters step-by-step, ensuring precise calibration. It may require some technical knowledge or consulting the vehicle's manual for guidance on specific calibration procedures.

In summary, calibrating the inverter is a vital process when adding an inverter to an EV. It ensures the inverter operates at its best, optimizing power transfer and overall vehicle performance. By carefully adjusting voltage, frequency, and power factor settings, you can achieve a well-balanced and efficient system, contributing to a longer-lasting and more reliable electric vehicle.

Electric Vehicle Fire Incidents: Unraveling the Truth Behind the Flames

You may want to see also

Frequently asked questions

No, you cannot directly connect an inverter to the battery pack of an electric vehicle (EV). Inverters are typically used to convert direct current (DC) to alternating current (AC) for household or industrial use. EVs have a sophisticated power electronics system that manages the flow of energy between the battery, motor, and other components. Directly connecting an inverter may damage the vehicle's electronics and is not recommended.

Adding an inverter to an EV requires careful consideration and planning. Here's a general process: First, assess your energy needs and the type of inverter suitable for your EV. Inverters designed for EVs are often called "EV inverters" or "vehicle inverters." These inverters are specifically engineered to handle the high-voltage DC power from the EV battery. You'll need to install the inverter in a location that provides adequate ventilation and cooling. It should be mounted securely and close to the battery pack for efficient power transfer. Ensure that the inverter is compatible with your EV's charging port and power electronics. Professional installation is highly recommended to ensure safety and proper integration with the vehicle's systems.

Yes, adding an inverter to your EV will likely result in a decrease in range. Inverters convert the DC power from the battery to AC power, which is then used to run household appliances or other AC-powered devices. This conversion process is not 100% efficient, and some energy is lost as heat. Additionally, the inverter system adds weight and complexity to the vehicle, which can further impact efficiency. It's important to consider the trade-offs and ensure that the inverter is used judiciously to minimize range loss.

Absolutely, there are legal and safety considerations to keep in mind. Modifying or adding components to an EV often requires compliance with local regulations and standards. Always check with your local authorities and EV manufacturer's guidelines. Safety is critical; improper installation or using incompatible inverters can lead to electrical hazards, fire risks, or damage to the vehicle. It is essential to follow manufacturer instructions, use approved components, and seek professional assistance if needed to ensure a safe and compliant installation.