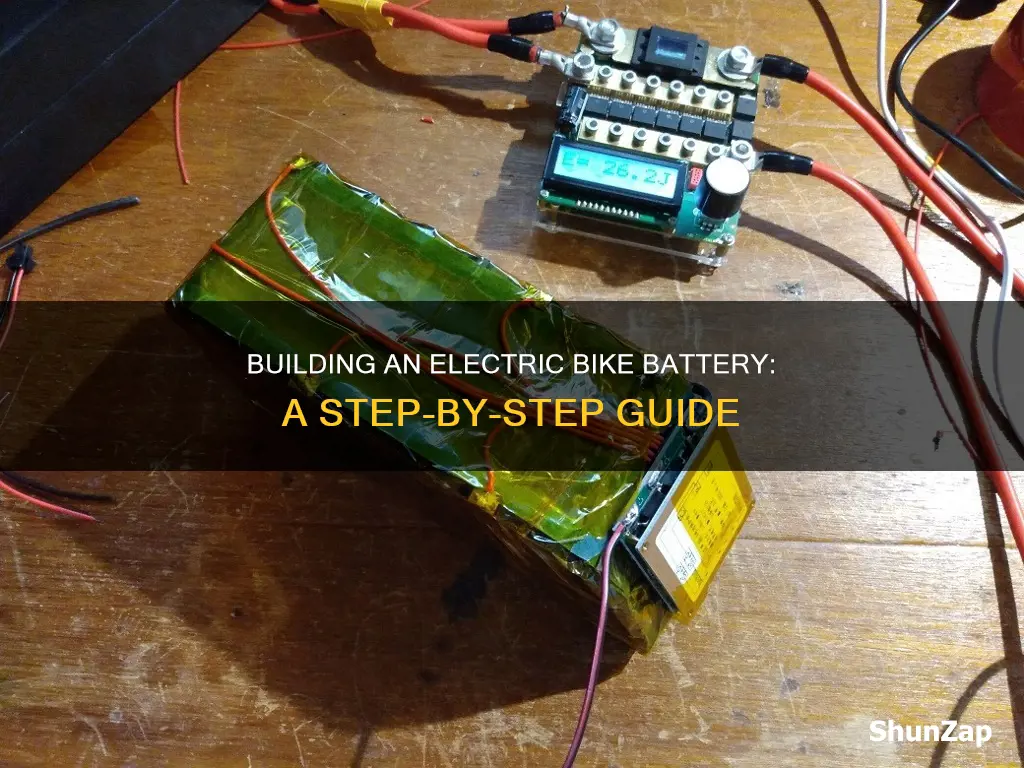

Building an electric bike battery is a complex process that requires careful planning and execution. The process involves selecting and assembling individual cells, connecting them in parallel or series to create a battery pack, and ensuring the battery matches the voltage, current, and power requirements of the electric bike. While building an electric bike battery can result in significant cost savings compared to purchasing a pre-made battery, it is important to approach the project with caution due to the potential hazards involved.

What You'll Learn

Choosing the right cells

Cell Type:

The most common cell type used in electric bike batteries is the 18650-format lithium-ion cell. These cells offer a good balance between size, performance, and cost. However, other cell types like the 21700-format cells or pouch cells are also available, each with its own advantages and disadvantages. For example, 21700-format cells developed by Panasonic in partnership with Tesla offer higher energy density but are more expensive and less readily available. Pouch cells, on the other hand, require additional structure when building a pack but can maximize space efficiency.

Cell Capacity:

The capacity of the cells you choose will depend on your intended usage. For short commutes and leisurely rides, a battery capacity of 5-10 Ah is typically sufficient. However, if you plan on taking longer rides or need more power, consider cells with higher ampere-hours (Ah) ratings, such as those in the 10-20 Ah range or higher. Keep in mind that higher-capacity cells will generally result in extended riding distances on a single charge.

Cell Voltage:

The voltage of the cells is another important consideration. Higher voltages, such as 48V, generally pack more watt-hours (Wh) into the same physical space, allowing you to go further. This is particularly important if you plan to ride in challenging conditions like hilly terrain or high winds, as these factors can drain your battery more quickly. Remember that the voltage of your cells should match the voltage of your Battery Management System (BMS) to ensure compatibility.

Cell Quality:

When choosing cells, it's essential to prioritize quality. Look for reputable sellers and well-known brands like Samsung or LG. While cost is a factor, be cautious of extremely low-priced cells, as they may not perform as expected or be damaged. It's worth investing in high-quality cells to ensure the performance, longevity, and safety of your electric bike battery.

Cell Arrangement:

The way you arrange the cells within your battery pack also matters. You can connect the same-type electrodes of multiple cells in parallel, effectively creating one large cell with increased capacity. Additionally, ensure that the cells are at the same level of charge when you first connect them. This will help you maintain consistent performance and avoid any potential issues.

In summary, choosing the right cells for your electric bike battery involves considering cell type, capacity, voltage, quality, and arrangement. By selecting the appropriate cells and assembling them correctly, you can build a safe, high-performance battery that meets your specific riding needs.

Electric Bikes in New South Wales: Legal or Not?

You may want to see also

Using a spot welder

When using a spot welder, the first step is to gather the necessary materials and equipment. This includes a battery, nickel strip, copper electrodes, and a welding machine. The battery provides the power for the welding process, while the nickel strip is used to connect the battery cells. The copper electrodes are an essential component of the welding machine, which is the tool that creates the weld.

There are different types of welding machines available, such as the large jaw spot welders and battery spot welders. Battery spot welders have the electrodes on the same side, while large jaw spot welders have the electrodes on different sides. Additionally, welding machines can be classified as hobby-level or professional. Hobby models typically cost around $200, while professional models can be ten times more expensive. It is worth noting that the quality of hobby models can vary significantly, even among identical models from the same seller.

Once the equipment is assembled, the next step is to set up the welding machine. This involves positioning the copper electrodes correctly and adjusting the current to a low setting, especially if it is your first time using the machine. It is recommended to perform a test weld by placing the battery cells and nickel strip below the probes and lifting them until the welding arms raise high enough to initiate the weld. A successful test weld will leave two dots on the nickel strip, and it should not come off with hand pressure.

After confirming that the welding machine is functioning correctly, you can proceed with welding the battery. This involves carefully laying the nickel strip over the battery cells and ensuring that it covers all the terminals. The specific technique may vary depending on the type of welding machine used. For example, with handheld probes, the nickel strip is lifted against the probes to initiate the weld. It is important to follow the safety precautions and guidelines provided by the manufacturer of the welding machine to ensure a safe and successful welding process.

Best Electric Bikes with Removable Batteries: Ultimate Guide

You may want to see also

Battery Management System (BMS)

A Battery Management System (BMS) is a crucial component of an electric bike battery, responsible for monitoring and regulating the battery's performance and health. It ensures that all the cells within the battery are balanced during charging and discharging, preventing over-depletion or overcharging.

The BMS plays a vital role in maintaining the voltage and current levels of the battery. When building a battery, it is essential to match the BMS's voltage to the battery voltage. For instance, a 36V battery requires a 36V BMS, also known as a 10s BMS, indicating 10 cells in series. Similarly, a 48V battery uses a 13s BMS, and a 52V battery requires a 14s BMS.

The BMS rating is another critical factor to consider. It determines the continuous current capacity of the battery. For instance, if you want your battery to handle 20A continuously, choose a BMS rated at or above 20A. A higher rating provides a safety buffer and ensures the BMS does not become a limiting factor in the battery's performance.

Additionally, some BMS systems offer temperature monitoring, which is an essential safety feature. Batteries can generate significant heat while delivering high currents, and if they get too hot, they pose a fire risk. The temperature monitoring function can mitigate this risk by shutting down the battery when it exceeds a safe temperature threshold.

When building an electric bike battery, it is important to consider the BMS as a key component. It not only regulates the battery's performance but also provides essential protection to ensure the safe operation of the battery and the overall electric bike system.

A Beginner's Guide to Operating Electric Bikes

You may want to see also

Voltage and current rate

When building an electric bike battery, it is important to understand the concepts of voltage, current rate, and wattage to ensure optimal performance and safety.

Voltage

Voltage, measured in volts (V), is the electrical force or pressure that drives the electric current through a circuit. It determines how fast the electrons move through the system. In an electric bike battery, voltage is an indicator of the battery's power and speed. Higher voltage generally means higher power and faster speed, while lower voltage results in slower performance. For example, a 48V battery will outperform a 36V battery when climbing steep hills as the 36V system will have to work harder to produce the same results.

Each battery has an operational voltage range, with a maximum charge and a minimum charge. Operating outside this range can damage the battery. For instance, a 52V battery might have a maximum voltage of 58V when fully charged and a minimum of 46V when fully discharged, with 52V being the midpoint or nominal voltage.

The voltage of an electric bike battery is also dependent on the number of battery cells and how they are arranged. All lithium-ion cells are 3.7V, and by wiring them in series, you can achieve the desired total voltage. For example, ten individual 3.6V cells in series will give you 36V.

Current Rate

Current rate, also known as amperage or amps, is measured in amperes (A) and indicates the strength or volume of the electric current flowing through the system. Amp-hours (Ah) is a related measurement that indicates the capacity of the battery or how much energy it can deliver over an hour. A 10 Ah battery can deliver 10 amps in one hour, 1 amp in 10 hours, or any combination depending on the power requirements. The amp-hours are determined by the number of clusters of battery cells arranged in parallel.

When choosing a Battery Management System (BMS), it is crucial to match the voltage and current rate to your battery. The BMS monitors the cells during charging and discharging, protecting them from over-draining or overcharging. For instance, if you are building a 36V battery, you will need a matching 36V BMS (also called a 10s BMS, indicating 10 cells in series).

Wattage

Wattage, measured in watts (W), is the rate at which energy is transferred or consumed by the electric motor. It is calculated by multiplying the voltage by the amperage (V x A = W). For example, a 36V battery with 10A will have a wattage of 360W.

While wattage is important, it does not solely determine the performance of the electric bike as it is subject to change. The wattage of a fully charged battery will be higher than that of an empty battery due to voltage changes. Additionally, factors such as riding conditions (e.g., flat land, hills, load) will influence the power output.

Electric Bike Waterproofing: What You Need to Know

You may want to see also

Cell connections

When connecting your battery cells, you have a few options. The first is to solder them together, but this can create a lot of heat that may damage the cells and prevent them from reaching their full capacity. A more popular method is to use a spot welder, which can be purchased for around $150. You can also buy a more advanced spot welder with hand probes for a higher price. If you don't want to invest in a spot welder, you can buy cylindrical cans with tabs already spot-welded on them, which allows for easier soldering with reduced heat.

To join your cells together, you will need to use nickel strips. Make sure to use 100% nickel strips, as nickel-plated steel has a much higher resistance and is often passed off as genuine nickel strips by vendors. You can use the spark test or the saltwater test to ensure that you have received genuine 100% nickel strips.

When connecting your cells, it is important that they are at the same level of charge. If you connect a fully charged cell in parallel to a cell with a low charge, the high cell will try to charge the low cell, which can be dangerous.

The number of cells you will need depends on the power output you desire. For example, if you want a 30A continuous pack and are using Samsung 26F cells, you will need at least 6 cells in parallel since these cells can only provide 5A continuously.

Finally, you will need a Battery Management System (BMS) to monitor your cells during charging and discharging. This will protect your cells from getting drained too far or getting overcharged. When choosing a BMS, you need to match the voltage and current rate of your battery. For example, if you are building a 36V battery, you will need a 36V BMS or a 10s BMS, which means 10 cells in series. You will also want to consider the discharge current of your battery and choose a BMS that is rated higher than this to give you a safety buffer.

Electric Bikes: Legal Status and Riding Regulations

You may want to see also

Frequently asked questions

You can use a lithium battery for your electric bike. The type of lithium battery you use will depend on the power output you require.

You will need a BMS (Battery Management System) to monitor your cells during charging and discharging, nickel strips to join your cells together, and a spot welder to connect the cells.

You will need to match the voltage of your BMS to the voltage of your battery. For example, if you are building a 36V battery, you will need a 36V BMS. You will also need to consider the current rate of your BMS.

There are a variety of cells on the market, each with its own advantages and disadvantages. For example, Panasonic 18650pf cells can deliver a maximum of 10A continuously, while Sanyo 18650GA cells provide 3.5AH and 10A continuously. If you don't need as much power, you can use the more economical Samsung 26F cells, which provide 2.6AH and 5A continuous.

You can solder the cells together, but this can generate a lot of heat and potentially damage the cells. It is recommended to use a spot welder to connect the cells safely.