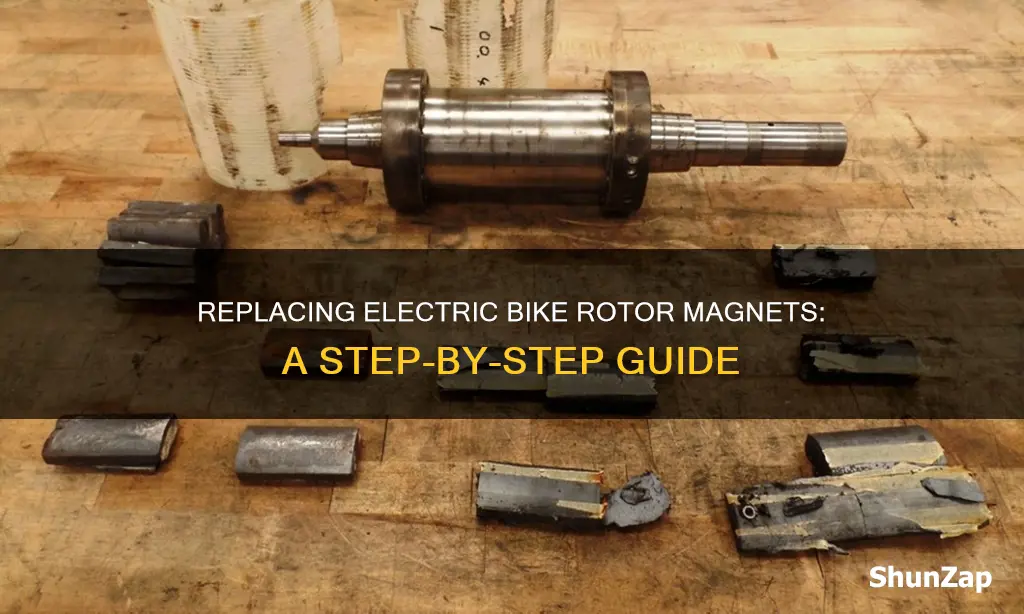

Electric bikes use permanent magnets on the rotor to operate. These magnets can be made of neodymium-boron-iron, samarium-cobalt, or ferrite. They can be mounted with adhesive on the surface of the rotor core or inset into the rotor core surface. In this article, we will discuss how to replace these permanent magnets on an electric bike rotor.

| Characteristics | Values |

|---|---|

| Type of magnet | Niobium, neodymium, samarium-cobalt, or ferrite |

| Where to buy | eBay |

| How to attach | JB Weld, epoxy, hot glue |

| How many to buy | A handful |

| Where to place | Across from the pickup, at about the same distance |

| How to keep the assembly | Clean and free from dirt, oil and grease |

What You'll Learn

Where to buy replacement magnets

Replacement magnets for electric bikes can be purchased from a variety of online retailers, including Amazon, eBay and Automaxx India.

On Amazon, you can find replacement magnets as part of an electric sensor, pedal assist sensor assistant system. These are designed to be used with electric bicycles and are available with free delivery.

On eBay, you can find niobium magnets, which are cheap and can be used for electric bikes.

Automaxx India also offers a range of spare parts for electric scooters, including replacement neodymium magnets. They offer parts for popular brands such as Automaxx, Ola, Ather, TVS, Bajaj, Hero, Okinawa, Ampere, Benling, Pure-EV, and Jitendra-EV.

Designing an Electric Bike: A Comprehensive Guide

You may want to see also

How to attach the magnets

To attach the magnets to the rotor of an electric bike, you can use a small amount of epoxy or hot glue. You can also use JB Weld to attach the magnet to the rotor.

If you are using a centre-lock rotor, you can place a small Nd magnet on the steel rotor. This should hold fine for over a year, but you may want to add epoxy around it to prevent slippage.

If you are using a 6-bolt rotor, you can attach the magnet to the centre-lock adapter ring using hot glue. This will prevent the magnet from shifting around.

You can also buy tiny niobium magnets from eBay and use these to attach the rotor to the bike. Place the magnet across from the pickup, at about the same distance, and JB Weld it into place.

Fixing Your Razor Electric Dirt Bike: Step-by-Step Guide

You may want to see also

How to prevent slippage

To prevent slippage when replacing permanent magnets on the rotor of an electric bike, there are several methods you can use.

Firstly, ensure that the rotating assembly is clean and free from dirt, oil and grease. This will provide a better surface for the magnet to adhere to and reduce the chances of slippage.

Secondly, consider the type of magnet you are using. Small Nd magnets, also known as neodymium-boron-iron magnets, can be used and held in place with epoxy or glue. This will create a strong bond and prevent the magnet from slipping. You can also use niobium magnets, which are cheap and readily available on eBay.

When applying the adhesive, use a small amount to avoid any mess. A dab of hot glue or epoxy around the magnet should be sufficient to hold it in place and prevent slippage.

Additionally, the placement of the magnet is important. Place the magnet across from the pickup, at about the same distance, and JB Weld it into place. This will ensure that the magnet is secure and less likely to slip.

By following these steps, you can effectively prevent slippage when replacing permanent magnets on the rotor of your electric bike.

Repairing Electric Bike Controllers: A Step-by-Step Guide

You may want to see also

How to clean the rotating assembly

To clean the rotating assembly of an electric bike, you should keep it free from dirt, oil and grease. You can use a bucket of warm water mixed with mild soap and a sponge or soft-bristled brush to gently scrub the bike frame and parts. If the wheels and tires are particularly muddy or dirty, use a different brush. You can also use a gear cleaning brush or toothbrush with firm bristles to scrub each cog, removing grime from the teeth and sides. Turn the cranks periodically to rotate the cogs and expose their teeth. Grease can accumulate between the cogs, so it is important to clean inside these gaps as well. Many gear cleaning brushes have a narrow hooked end with notches that are specifically designed for cleaning the spaces between cogs and removing caked-up grime. Once all the components of the drivetrain have been thoroughly scrubbed and cleaned, gently spray down these parts with a hose. You can also fill the chain cleaner with degreaser, then pedal the bike backwards, allowing the chain to move through the chain cleaner. Rotate the drivetrain at least 30-40 rotations. Hold a rag lightly on the chain so it can still move and pedal the drivetrain backwards. This will help wipe any excess grime off of your chain. Take a new rag and put a little bit of the degreaser onto it. Use this rag/cloth with the degreaser on it and “floss” in between the cassette teeth on the rear wheel. This will help clean the grime that has gotten in between the cassette rings.

A Simple Guide to Installing Electric Start on Pit Bikes

You may want to see also

How to use adhesive to attach magnets to the rotor core

To attach magnets to the rotor core of an electric bike, you can use an adhesive such as JB Weld, epoxy or hot glue.

First, ensure that the rotating assembly is clean and free from dirt, oil and grease. Then, place the magnet across from the pickup, at about the same distance. Apply the adhesive to the magnet and press it into place on the rotor core. Hold it in place until the adhesive sets.

If you are using JB Weld, follow the instructions on the package to mix the two-part epoxy and apply it to the magnet. For epoxy, ensure that the surface of the rotor core is clean and dry before applying the epoxy and pressing the magnet into place.

Hot glue can also be used to attach magnets to the rotor core. Again, ensure that the surface is clean and dry, then apply the hot glue to the magnet and press it into place.

It is important to use an adhesive that is strong enough to hold the magnet in place and prevent slippage. You may also want to consider the temperature range and weather resistance of the adhesive, especially if you plan to ride your bike in extreme conditions.

Additionally, it is a good idea to have some extra magnets on hand in case one becomes loose or falls off. You can purchase small magnets for this purpose from eBay or other online retailers.

Folding the Jetson Electric Bike: A Step-by-Step Guide

You may want to see also

Frequently asked questions

You can buy replacement magnets online, either from eBay or specialist suppliers. You can use epoxy or hot glue to attach the magnets to the rotor.

Magnets made from neodymium-boron-iron, samarium-cobalt, or ferrite are all suitable for use in electric motors.

You can use epoxy or hot glue to prevent the magnets from slipping.