Electric vehicles (EVs) have revolutionized the automotive industry, and at the heart of this transformation are their batteries. The question of whether EV batteries are direct current (DC) or alternating current (AC) is an important one, as it directly impacts the vehicle's performance and charging infrastructure. In this paragraph, we will explore the nature of EV batteries and their relationship with electricity to provide a comprehensive understanding of this fundamental aspect of electric mobility.

| Characteristics | Values |

|---|---|

| Battery Type | DC (Direct Current) |

| Voltage | Typically 300-400 volts |

| Capacity | Varies widely, ranging from 30 kWh to over 100 kWh |

| Energy Density | High, allowing for compact designs |

| Charging | Uses DC-DC converters to convert AC (Alternating Current) from the grid to DC for the battery |

| Power Delivery | Direct power to the electric motor, no need for inversion |

| Efficiency | Generally high, with minimal energy loss during charging and discharging |

| Range | Varies by model, often 100-400 miles on a single charge |

| Recycling | Possible, with efforts to recover valuable materials like lithium and cobalt |

| Safety | Designed with safety mechanisms to prevent overheating, short circuits, and other hazards |

| Weight | Heavier than some traditional batteries but lighter than lead-acid batteries |

| Lifespan | Typically 8-10 years, with degradation over time |

What You'll Learn

- Battery Chemistry: Understanding the materials and processes used in EV battery construction

- Power Electronics: How converters and inverters manage DC/AC power conversion in EVs

- Charging Systems: Exploring different charging methods and their impact on battery health

- Energy Storage: The role of batteries in storing and releasing energy efficiently

- Safety Mechanisms: Preventing overheating, short circuits, and other hazards in EV batteries

Battery Chemistry: Understanding the materials and processes used in EV battery construction

The construction of electric vehicle (EV) batteries involves intricate battery chemistry, carefully selecting materials, and precise manufacturing processes to ensure optimal performance and longevity. These batteries are typically designed to store and release electrical energy efficiently, powering the vehicle's electric motor. At the heart of these batteries are electrochemical cells, which convert chemical energy into electrical energy through redox reactions.

One of the key materials in EV batteries is lithium, a highly reactive metal that serves as the anode or negative electrode. Lithium-ion batteries, the most common type used in EVs, rely on lithium-based materials to facilitate the movement of lithium ions between the anode and cathode during charging and discharging. The anode material, often a carbon-based material like graphite, provides a large surface area for lithium ions to attach and detach, enabling efficient charge storage and release.

Cathode materials play a crucial role in battery chemistry. Common cathode materials include lithium cobalt oxide (LiCoO2), lithium nickel manganese cobalt oxide (NMC), and lithium iron phosphate (LFP). These materials offer varying energy densities, voltage profiles, and thermal stability, allowing engineers to tailor the battery's performance to specific EV requirements. For instance, NMC cathodes provide higher energy density and improved thermal stability compared to LiCoO2, making them attractive for long-range EVs.

The manufacturing process involves several steps, starting with the synthesis of the chosen cathode and anode materials. These materials are then mixed with binders and conductive additives to form a slurry, which is coated onto current collectors (typically metal foils) to create the electrodes. The electrodes are then assembled into cells, with separators inserted to prevent short circuits while allowing ion movement.

After assembly, the cells undergo a series of processes, including formation, aging, and quality control. Formation involves charging and discharging the cells to establish the electrochemical reactions and balance the electrode materials. Aging allows the battery to stabilize, improving its performance and longevity. Finally, the batteries are integrated into the EV's power system, where they provide the necessary energy for propulsion. Understanding these battery chemistry principles is essential for optimizing EV battery performance, safety, and sustainability.

Electric Vehicles: Unraveling the Mystery of Accelerated Tire Wear

You may want to see also

Power Electronics: How converters and inverters manage DC/AC power conversion in EVs

The power electronics in electric vehicles (EVs) play a crucial role in managing the conversion between direct current (DC) and alternating current (AC) to ensure efficient operation and performance. This is a critical aspect of EV design, as it directly impacts the vehicle's range, efficiency, and overall driving experience.

At the heart of this process are converters and inverters, sophisticated electronic devices that facilitate the conversion of electrical energy. Converters are used to change the voltage and current levels of DC power, typically from the battery pack, to match the requirements of various vehicle systems. For instance, converters can step up or step down the voltage to match the needs of the electric motor, charging system, or auxiliary electronics. This DC-to-DC conversion is essential for optimizing energy usage and ensuring that the vehicle's electrical systems operate at their most efficient levels.

Inverters, on the other hand, are responsible for converting the DC power from the battery into AC power, which is the standard form of electricity used in most household and industrial applications. In an EV, the inverter's primary function is to supply AC power to the electric motor, enabling the vehicle to move. The inverter's design is critical, as it must provide the required power at the right frequency and voltage to ensure smooth and efficient motor operation. Modern inverters in EVs are highly efficient and can rapidly adjust the power output to match the driver's demands, providing a seamless driving experience.

The management of power electronics in EVs is a complex task, requiring precise control and regulation. The converters and inverters must work in harmony to ensure that the power distribution is balanced and efficient. For example, during regenerative braking, the inverter converts the motor's power back into DC power, which is then stored in the battery. This process requires careful management to prevent overcharging and ensure the battery's longevity.

Additionally, power electronics in EVs are designed to handle high-voltage and high-current levels, which can be challenging due to the potential for energy losses and heat generation. To mitigate these issues, advanced cooling systems and heat management techniques are employed to maintain optimal operating temperatures. The efficiency of these power electronics is further enhanced by the use of high-frequency switching and sophisticated control algorithms, allowing for rapid and precise adjustments in power levels.

In summary, the converters and inverters in electric vehicles are integral to the efficient management of DC and AC power. They enable the vehicle to draw power from the battery, supply it to the motor, and handle various other electrical tasks. The continuous development of power electronics technology is driving the improvement of EV performance, range, and overall sustainability.

Ford's Electric Future: A Doubtful Transition?

You may want to see also

Charging Systems: Exploring different charging methods and their impact on battery health

The charging systems of electric vehicles (EVs) are a critical component, as they directly impact battery health and performance. When it comes to charging, there are primarily two types of systems: direct current (DC) and alternating current (AC) charging. Understanding these methods is essential for EV owners to optimize their battery's longevity and efficiency.

DC charging, often referred to as fast charging, is the more efficient and rapid method. It involves directly supplying DC power to the battery, bypassing the onboard AC-to-DC converter. This process is faster because it eliminates the need for the battery to convert AC power to DC, which can be energy-intensive. DC fast chargers are commonly found along highways and in public charging stations, allowing for quick top-ups during long-distance travel. The high-power input can heat the battery, so proper temperature management is crucial during this charging method.

On the other hand, AC charging is typically used for slower, overnight charging at home. Most EVs come equipped with an onboard AC-to-DC converter, which converts the AC power from the wall outlet to DC for the battery. This method is generally safer and more efficient for home charging due to the lower power levels involved. AC charging is slower compared to DC, but it is designed to be gentle on the battery, ensuring a longer lifespan.

The impact of these charging methods on battery health is a key consideration. DC charging, while faster, can lead to higher stress on the battery cells due to the rapid power input. This may result in increased degradation over time, especially if not managed properly. AC charging, being slower, puts less strain on the battery, making it a more gentle option for regular use. However, it may not be as convenient for quick top-ups during long journeys.

To optimize battery health, EV owners should consider their charging habits. For frequent long-distance travel, investing in a DC fast charger can be beneficial, ensuring a quick charge and reducing the time spent on the road. For daily use, especially for those with home charging options, AC charging is generally recommended to maintain battery longevity. Additionally, using smart charging techniques, such as scheduling charges during off-peak hours, can further enhance battery health and efficiency.

Electric Vehicle Access: California HOV Lane Eligibility Explained

You may want to see also

Energy Storage: The role of batteries in storing and releasing energy efficiently

The role of batteries in electric vehicles (EVs) is pivotal, as they serve as the primary energy storage system, enabling efficient power supply and management. These batteries are designed to store electrical energy and release it as needed to power the vehicle's electric motor. The efficiency of this process is crucial for the overall performance and range of electric cars.

In the context of electric vehicles, batteries are typically direct current (DC) systems, which is a fundamental aspect of their design and functionality. DC batteries are commonly used in EVs due to their ability to provide a steady and continuous flow of electricity. When an EV is plugged into a charging station, the alternating current (AC) from the grid is converted into DC by an onboard charger, which then charges the battery. This DC battery system is optimized to store energy efficiently and release it when required, ensuring a smooth and reliable power supply for the vehicle's operations.

The efficiency of energy storage and release is a critical factor in the success of electric vehicles. Modern EV batteries are engineered to have high energy density, allowing them to store a significant amount of energy in a relatively compact space. This is essential for achieving the desired range and performance of the vehicle. During acceleration or when additional power is needed, the battery rapidly releases stored energy, providing the necessary boost to the electric motor. This efficient energy management system ensures that the vehicle can handle various driving conditions and maintain a consistent power output.

Furthermore, the design of these batteries often incorporates advanced technologies such as lithium-ion chemistry, which offers high energy density, long cycle life, and the ability to handle rapid charge and discharge cycles. These features are vital for the overall efficiency and longevity of the energy storage system in EVs. The batteries are also designed to manage temperature and state of charge, optimizing performance and safety.

In summary, the role of batteries in electric vehicles is to efficiently store and release energy, providing the necessary power for propulsion. The use of DC batteries and advanced energy storage technologies ensures that EVs can offer a practical and reliable alternative to traditional internal combustion engines. As the technology continues to evolve, we can expect further improvements in energy efficiency, range, and overall performance, making electric vehicles an increasingly attractive and sustainable transportation option.

Elevate Your EV: Upfit Solutions for Electric Vehicles

You may want to see also

Safety Mechanisms: Preventing overheating, short circuits, and other hazards in EV batteries

The safety of electric vehicle (EV) batteries is a critical aspect of the overall performance and reliability of these vehicles. One of the primary concerns in EV battery technology is the prevention of overheating, short circuits, and other potential hazards that could lead to fires, explosions, or performance degradation. These safety mechanisms are designed to protect both the battery and the vehicle, ensuring the well-being of passengers and the environment.

Overheating is a significant issue in EV batteries, primarily due to the chemical reactions occurring within the cells. To combat this, manufacturers employ various strategies. One common approach is the use of cooling systems, such as liquid or air cooling, to maintain optimal temperatures. These systems are strategically placed within the battery pack to efficiently dissipate heat. Additionally, advanced battery management systems (BMS) monitor temperature continuously, allowing for real-time adjustments to prevent overheating. The BMS can detect and respond to temperature anomalies, ensuring that the battery operates within safe limits.

Short circuits, another potential hazard, can occur due to internal or external factors. To mitigate this risk, batteries are often designed with safety features like overcurrent protection. This involves the use of circuit breakers or fuses that can detect and interrupt excessive current flow, preventing short circuits and potential damage. Furthermore, the battery cells themselves are arranged in a way that minimizes the risk of short circuits, often with a protective layer or separator between them.

In addition to these measures, EV batteries also incorporate safety mechanisms to handle other potential hazards. For instance, pressure relief valves are installed to release excess pressure built up within the battery, which could otherwise lead to explosions. These valves are designed to activate when the internal pressure exceeds a safe threshold, allowing for a controlled release of gases. Furthermore, advanced BMS algorithms can detect and respond to various fault conditions, such as cell imbalance or excessive voltage, and initiate appropriate safety protocols.

The development of these safety mechanisms is an ongoing process, with continuous research and innovation aimed at improving EV battery safety. As technology advances, we can expect to see even more sophisticated safety features, ensuring that electric vehicles remain a reliable and secure mode of transportation. These safety measures are essential to gaining public trust and widespread adoption of electric vehicles, as they address the concerns related to battery performance and longevity.

Unraveling Tesla's Standby Power Mystery: Why Your EV Consumes More Electricity When Idling

You may want to see also

Frequently asked questions

In electric vehicles, the term "DC" typically refers to direct current, which is the type of electrical current used in the vehicle's battery pack. These batteries store energy in a direct current format, which is then converted to alternating current (AC) for use in the vehicle's electrical systems. So, while the battery itself stores DC, the vehicle's overall electrical architecture uses AC.

Electric vehicles require AC power for most of their operations, including powering the electric motor, charging the battery, and running accessories. The inverter, a crucial component, converts the DC power from the battery to AC power, which can then be utilized by the vehicle's systems.

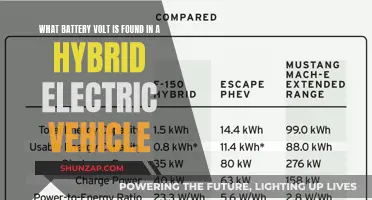

No, electric vehicle batteries can vary in voltage and current specifications. Different manufacturers use various battery chemistries and designs, resulting in diverse voltage outputs. For instance, some common lithium-ion battery packs in EVs have voltages ranging from 300V to 400V, while the current capacity can vary widely depending on the specific battery design and intended use.

The DC-AC conversion process has minimal impact on the vehicle's performance. Inverters are designed to handle the power conversion efficiently, ensuring that the vehicle's electrical systems receive the required AC power. Modern inverters are highly efficient and can quickly convert DC to AC, allowing for smooth operation and optimal performance of the electric vehicle.

Charging an electric vehicle with a standard DC power supply is not recommended. Most electric vehicles use AC charging systems, which are designed to work with the vehicle's onboard AC-to-DC converter. Using a DC power supply directly may damage the vehicle's battery and electrical systems. It's always best to follow the manufacturer's guidelines for charging your specific electric vehicle model.