Electric vehicle batteries, a crucial component of modern eco-friendly transportation, have sparked concerns regarding the possibility of explosions. Despite the misconceptions, it is essential to understand that modern EV batteries are designed with advanced safety features to prevent such incidents. These batteries are rigorously tested and engineered to handle extreme conditions, ensuring that explosions are extremely rare. The focus on safety has led to the development of sophisticated cooling systems, pressure relief mechanisms, and protective casings, making the risk of battery explosions in electric vehicles minimal compared to traditional internal combustion engine vehicles.

What You'll Learn

- Battery Chemistry: Chemical reactions can cause overheating and gas formation, leading to explosions

- Temperature Sensitivity: Extreme temperatures can damage batteries and trigger thermal runaway, a potential explosion risk

- Manufacturing Defects: Faulty production can result in short circuits, overheating, and subsequent battery explosions

- Crash Impact: Collisions may damage batteries, causing fires or explosions due to electrical shorts

- Recycling Hazards: Improper recycling processes can release hazardous gases and lead to battery explosions

Battery Chemistry: Chemical reactions can cause overheating and gas formation, leading to explosions

The concern about electric vehicle (EV) battery explosions is a valid one, especially as these vehicles become more prevalent on our roads. While it is true that some incidents of battery-related fires and explosions have occurred, it is essential to understand the underlying chemistry to address this issue effectively.

At the heart of this matter is the battery chemistry, particularly the chemical reactions that occur within the battery cells. Most modern EVs use lithium-ion batteries, which are known for their high energy density and efficiency. These batteries consist of an anode (usually made of graphite), a cathode (often a metal oxide), and an electrolyte that facilitates the movement of ions between the two electrodes. During the charging and discharging cycles, lithium ions move from the anode to the cathode through the electrolyte, creating a flow of electrons that powers the vehicle.

However, under certain conditions, these chemical reactions can go awry, leading to overheating and gas formation. The anode and cathode materials undergo oxidation and reduction processes, respectively, which generate heat. If the battery is charged or discharged too rapidly, or if there is a manufacturing defect, the increased heat can cause the battery to overheat. This overheating can lead to a chain reaction, where the increased temperature accelerates the chemical reactions, potentially causing the battery to vent gases or even ignite.

The formation of gases is another critical aspect. As the lithium ions move between the electrodes, they can cause the electrolyte to break down, producing gases like hydrogen and carbon monoxide. These gases can build up pressure within the battery, leading to a potential explosion. In some cases, the gases may ignite, causing a fire. This is why it is crucial for EV manufacturers to employ safety mechanisms, such as pressure relief valves and advanced cooling systems, to mitigate these risks.

Understanding the chemistry behind these reactions is vital for developing effective safety measures. Researchers and engineers are continually working on improving battery designs, materials, and safety protocols to minimize the chances of explosions and fires. This includes the development of advanced cooling systems, improved battery management systems, and the use of safer, more stable electrolytes. By addressing these chemical processes, the industry aims to enhance the overall safety of electric vehicles and alleviate the concerns associated with battery explosions.

Electric Vehicles: Are They Worth the Price Tag?

You may want to see also

Temperature Sensitivity: Extreme temperatures can damage batteries and trigger thermal runaway, a potential explosion risk

Extreme temperatures can significantly impact the performance and safety of electric vehicle (EV) batteries, posing a serious concern for both drivers and manufacturers. This sensitivity to temperature is a critical aspect of understanding the potential risks associated with EV battery explosions.

When exposed to high temperatures, EV batteries can experience thermal degradation, which leads to a decline in their overall performance and lifespan. The internal components of the battery, including the electrolyte and electrodes, are particularly vulnerable. Prolonged exposure to heat can cause the electrolyte to dry out, leading to reduced conductivity and potential damage to the battery's structure. This thermal stress can result in the formation of dendrites, which are metal deposits that can pierce the battery's separator, causing short circuits and further exacerbating the risk of thermal runaway.

Thermal runaway is a self-perpetuating process that can rapidly escalate and lead to battery explosions. It occurs when a battery's temperature rises beyond a critical threshold, triggering a series of events. Initially, the battery's temperature may increase due to internal resistance or external heat sources. As the temperature rises, the battery's internal pressure builds up, and if the pressure relief mechanisms fail, the battery can rupture, releasing flammable gases and potentially igniting. The fire can then spread to other components of the vehicle, posing a significant fire hazard.

To mitigate these risks, EV manufacturers employ various strategies. One approach is to design batteries with advanced cooling systems that help regulate temperature. These systems can include liquid or air cooling, which actively dissipate heat, ensuring that the battery operates within a safe temperature range. Additionally, some batteries are equipped with thermal management systems that monitor and control temperature, allowing for real-time adjustments to prevent overheating.

Another crucial aspect is the selection of appropriate battery materials and designs. Manufacturers choose materials that have a lower thermal expansion coefficient, reducing the risk of physical damage during temperature fluctuations. Furthermore, the use of safer chemistries, such as lithium-ion phosphate (LiFePO4), can enhance thermal stability and reduce the likelihood of thermal runaway. These materials are designed to operate within a narrower temperature range, making them less susceptible to extreme temperature-related issues.

In summary, the temperature sensitivity of EV batteries is a critical factor in ensuring their safe operation. Extreme temperatures can accelerate battery degradation, increase the risk of thermal runaway, and potentially lead to explosions. By implementing advanced cooling technologies, selecting appropriate materials, and adhering to manufacturer guidelines, EV owners can minimize these risks and contribute to the overall safety of electric vehicles.

Tesla's Revolutionary Journey: The Birth of Electric Vehicles

You may want to see also

Manufacturing Defects: Faulty production can result in short circuits, overheating, and subsequent battery explosions

Electric vehicle batteries, while generally reliable, can pose certain risks, including the potential for explosions, which are often attributed to manufacturing defects. These defects can occur at any stage of production, from the initial assembly to the final testing and packaging. One of the primary causes of battery explosions is short circuits. Short circuits occur when there is an unintended electrical connection within the battery, often due to faulty wiring, damaged insulation, or improper soldering. This can lead to a rapid increase in current flow, generating intense heat and potentially igniting the volatile chemicals inside the battery.

Another critical issue is overheating. Electric vehicle batteries are designed to operate within specific temperature ranges. If the battery is subjected to excessive heat, either during manufacturing or in normal use, it can lead to thermal runaway. This is a self-perpetuating cycle where the battery's temperature rises, causing further heat generation and potentially leading to an explosion. Overheating can result from various factors, including poor thermal management systems, faulty cooling fans, or even the presence of contaminants that interfere with heat dissipation.

Manufacturing processes play a crucial role in ensuring the quality and safety of electric vehicle batteries. Inadequate quality control measures can lead to the inclusion of defective components or the introduction of contaminants. For instance, if the separator between the battery's anode and cathode is damaged or improperly installed, it can cause a short circuit. Similarly, if the battery cells are not filled with the correct electrolyte or if there are manufacturing defects in the cell casing, it can lead to overheating and potential explosions.

To mitigate these risks, manufacturers employ rigorous quality control protocols. This includes visual inspections, electrical testing, and thermal simulations to identify potential issues before the batteries are installed in vehicles. Advanced manufacturing techniques, such as automated assembly lines and real-time monitoring systems, help minimize human error and ensure consistent quality. Additionally, post-production testing and certification processes are in place to verify that the batteries meet safety standards before they are released to the market.

Despite these measures, the risk of manufacturing defects remains a concern. It is essential for consumers to purchase electric vehicles and batteries from reputable manufacturers who adhere to strict quality control standards. In the event of a battery explosion, it is crucial to investigate the cause, which often involves a detailed examination of the manufacturing process and the specific defects that led to the failure. Understanding these manufacturing defects and their consequences is vital for improving battery safety and maintaining public confidence in electric vehicles.

The Green Revolution: Are Electric Vehicles the Ultimate Sustainable Choice?

You may want to see also

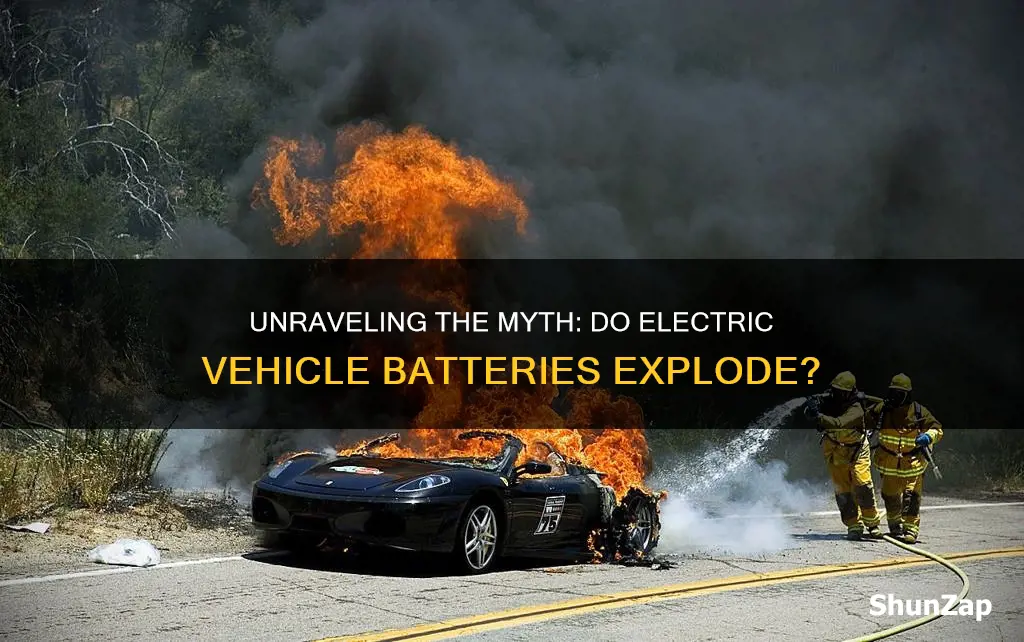

Crash Impact: Collisions may damage batteries, causing fires or explosions due to electrical shorts

Electric vehicle (EV) batteries are designed to be robust and safe, but like any complex system, they can be vulnerable to certain conditions, especially during a collision. When an EV is involved in a crash, the impact can have severe consequences for its battery pack. The high-voltage batteries used in EVs are typically located in the floor pan or beneath the passenger compartment, making them susceptible to damage in frontal, rear, or side-impact collisions.

In a collision, the force can cause physical damage to the battery cells, leading to short circuits or damage to the battery's internal components. This can result in the release of flammable electrolytes and the potential for electrical shorts. Electrical shorts occur when there is a direct connection between two points in the circuit that are not supposed to be connected, often due to damaged insulation or punctured cells. These shorts can lead to rapid overheating and the release of gases, which, in turn, can cause a fire or explosion.

The risk of fire or explosion is particularly high in lithium-ion batteries, which are commonly used in EVs. These batteries contain volatile components, and when damaged, they can ignite or explode. The intense heat generated during a collision can accelerate the decomposition of these materials, leading to a more severe incident. It is crucial for EV manufacturers to design battery packs with robust safety mechanisms to mitigate these risks.

To enhance safety, modern EVs incorporate various protective measures. These include advanced battery management systems that monitor temperature, pressure, and voltage, and can shut down the battery in case of an emergency. Additionally, some vehicles are equipped with fire suppression systems that can detect and extinguish fires quickly. However, despite these precautions, the potential for battery-related incidents in crashes remains a critical area of focus for EV manufacturers and regulatory bodies.

In summary, while electric vehicle batteries are generally safe, collisions can lead to significant damage, potentially causing fires or explosions due to electrical shorts. Understanding these risks is essential for both manufacturers and drivers to ensure the safe operation and maintenance of EVs.

Uncover the Hidden EV Tax Credits: A Comprehensive Guide

You may want to see also

Recycling Hazards: Improper recycling processes can release hazardous gases and lead to battery explosions

The improper recycling of electric vehicle (EV) batteries can pose significant risks and has been associated with several incidents, including battery explosions. These explosions are primarily caused by the release of hazardous gases during the recycling process, which can occur due to various factors. One of the main issues is the potential for thermal runaway, a self-perpetuating chain reaction that can rapidly increase the temperature of the battery, leading to an explosion. This phenomenon is often triggered by the presence of volatile organic compounds (VOCs) and other flammable materials within the battery.

During the recycling process, if the batteries are not handled and processed correctly, the intense heat generated can cause these flammable substances to ignite. For instance, nickel-cadmium (Ni-Cd) batteries, commonly used in older EVs, contain a high concentration of cadmium, a toxic metal. When these batteries are crushed or shredded without proper precautions, the release of hydrogen gas, a byproduct of the recycling process, can create a hazardous environment. Hydrogen is highly flammable and, when combined with the presence of oxygen, can lead to a powerful explosion.

Another critical factor is the release of toxic gases, such as sulfur dioxide and hydrogen sulfide, which can be released during the recycling of lithium-ion batteries. These gases are not only hazardous to human health but can also contribute to the degradation of the recycling equipment. In some cases, the release of these gases can lead to fires or explosions, especially if the recycling facility lacks adequate ventilation and safety measures.

To mitigate these risks, it is essential to implement strict safety protocols in EV battery recycling. This includes ensuring proper ventilation in recycling facilities, using specialized equipment to handle and process batteries, and employing trained personnel to monitor the process. Additionally, recycling companies should invest in advanced technologies that can detect and neutralize hazardous gases, preventing potential explosions. By adhering to these guidelines, the recycling industry can significantly reduce the likelihood of battery explosions and ensure a safer environment for both workers and the surrounding community.

In summary, the improper recycling of EV batteries can result in the release of hazardous gases, leading to thermal runaway and potential explosions. The presence of volatile materials and toxic substances within the batteries, coupled with inadequate recycling practices, creates a dangerous situation. Therefore, it is crucial for recycling facilities to prioritize safety measures and employ best practices to minimize the risks associated with EV battery recycling.

Unraveling Tesla's Standby Power Mystery: Why Your EV Consumes More Electricity When Idling

You may want to see also

Frequently asked questions

While it is a common misconception that electric vehicle batteries can explode, the reality is that such incidents are extremely rare. Modern EV batteries are designed with multiple safety mechanisms to prevent explosions. These include temperature monitoring, pressure relief valves, and advanced battery management systems that can detect and mitigate potential issues.

Battery explosions in EVs are primarily caused by extreme external factors or manufacturing defects. High temperatures, direct physical damage, or exposure to fire are the most common triggers. However, these events are often the result of accidents or misuse, and not a typical occurrence in everyday driving conditions.

There have been isolated incidents of EV battery explosions, but they are very uncommon. Most of these cases involve older battery designs or those that have been damaged or modified. With advancements in technology, modern EVs are much safer, and the likelihood of a battery explosion is significantly reduced.

To ensure the safety of your EV battery, follow the manufacturer's guidelines for charging and maintenance. Avoid exposing the battery to extreme temperatures, and never attempt to modify or repair it yourself. Regularly check for any signs of damage or unusual behavior, and always park your vehicle in a well-ventilated area to minimize fire risks.

If you notice any unusual behavior, such as unusual noises, smoke, or a strong odor, immediately pull over to a safe location and contact the manufacturer's emergency services or a qualified mechanic. Do not attempt to handle the situation yourself, as it may lead to further complications.