Electric vehicles, a rapidly growing segment in the automotive industry, have sparked curiosity about their inner workings. Unlike traditional internal combustion engines, electric vehicles operate on a different principle, eliminating the need for rods and pistons. These components, crucial in conventional engines for converting the reciprocating motion of pistons into rotational motion, are replaced in electric vehicles with advanced technologies such as electric motors and batteries. This unique design not only contributes to the efficiency and sustainability of electric vehicles but also sets them apart from their gasoline-powered counterparts.

| Characteristics | Values |

|---|---|

| Engine Type | Electric vehicles do not have traditional internal combustion engines with rods and pistons. |

| Power Source | Electric motors use electrical energy stored in batteries, eliminating the need for reciprocating pistons. |

| Energy Conversion | Instead of burning fuel, electric vehicles convert electrical energy into mechanical motion through electric motors. |

| Transmission | Many electric vehicles use single-speed transmissions or direct drive, simplifying the mechanism compared to traditional engines. |

| Efficiency | Electric motors are generally more efficient, converting a higher percentage of energy into useful work. |

| Maintenance | With fewer moving parts, electric vehicles often require less maintenance and have longer lifespans. |

| Performance | Electric motors provide instant torque, resulting in quick acceleration and smooth power delivery. |

| Environmental Impact | The absence of rods and pistons contributes to lower emissions and reduced environmental impact. |

| Noise | Electric vehicles operate more quietly due to the lack of engine noise. |

| Range | Battery technology and charging infrastructure determine the range of electric vehicles, not the engine design. |

What You'll Learn

- Engine Design: Electric motors lack traditional piston-based components like rods and pistons

- Power Generation: EVs convert electrical energy into motion without internal combustion

- Transmission: Gear systems in EVs transmit power, but not through piston-rod mechanisms

- Efficiency: Electric powertrains offer higher efficiency without the need for piston-rod assemblies

- Maintenance: EVs require less maintenance due to the absence of piston-rod engine components

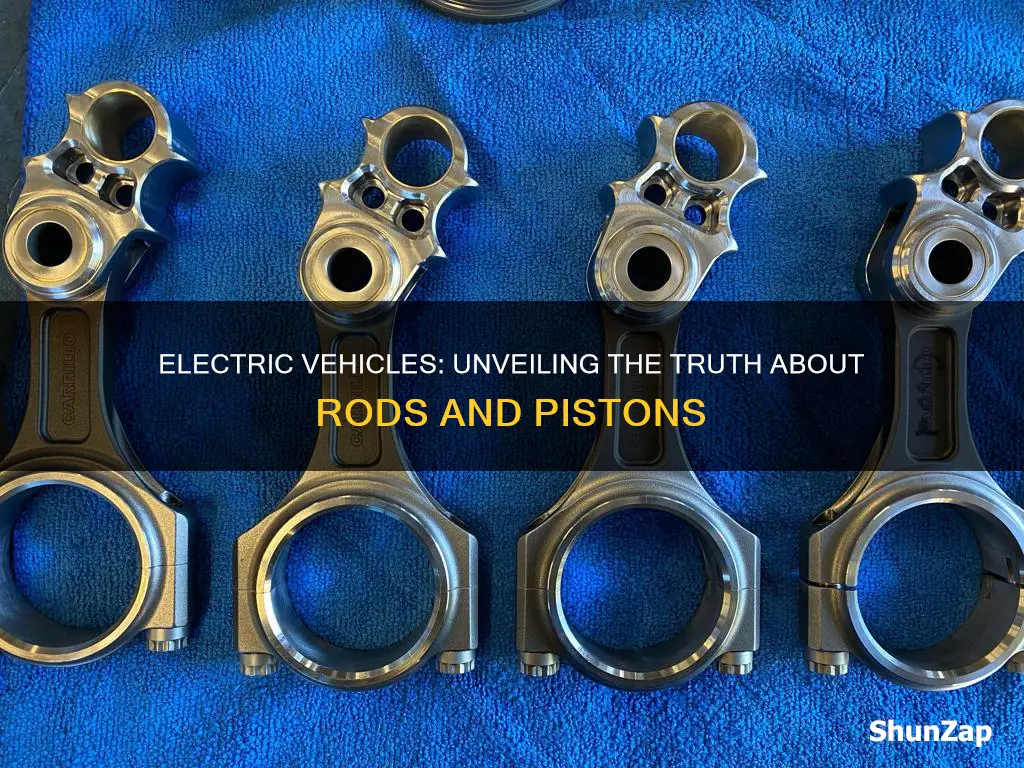

Engine Design: Electric motors lack traditional piston-based components like rods and pistons

Electric vehicles have revolutionized the automotive industry, offering a cleaner and more efficient mode of transportation. One of the key differences between traditional internal combustion engines and electric motors lies in their design and functionality. When it comes to engine design, electric motors present a unique approach that diverges from the conventional piston-based systems.

In traditional piston engines, the power is generated through a series of intricate movements involving rods and pistons. These components work in harmony to convert the chemical energy from fuel into mechanical motion. However, electric motors operate on a fundamentally different principle. They utilize electrical energy to produce rotational motion, which is then converted into linear motion through the use of gears and other mechanical systems. This fundamental difference in operation means that electric motors do not require the traditional piston-based components.

The absence of rods and pistons in electric motors is a result of their unique architecture. Electric motors typically consist of a stator, which is a stationary part with coils of wire, and a rotor, which is the rotating part. The rotor is often designed with permanent magnets or electromagnets, creating a magnetic field that interacts with the stator's magnetic field. This interaction generates a torque, causing the rotor to rotate. The rotational motion is then transferred to the vehicle's wheels through a system of gears and driveshafts.

This design has several advantages. Firstly, electric motors offer a more compact and lightweight solution compared to traditional engines. Without the need for rods and pistons, the motor can be designed with a smaller footprint, allowing for more efficient use of space within the vehicle. Additionally, electric motors provide a smoother and quieter driving experience. The absence of piston-rod interactions eliminates the harsher sounds and vibrations associated with traditional engines, contributing to a more comfortable and refined driving environment.

Furthermore, the efficiency of electric motors is enhanced by their direct conversion of electrical energy into mechanical energy. In contrast, traditional engines experience energy losses due to the complex processes of combustion and expansion. Electric motors can achieve higher efficiency, resulting in improved performance and reduced energy consumption. This efficiency is a significant factor in the growing popularity of electric vehicles, as it contributes to their environmental benefits and long-term cost-effectiveness.

In summary, electric motors in vehicles are designed without the traditional piston-based components like rods and pistons. This unique design allows for a more compact, efficient, and environmentally friendly power source. The absence of these components is a key factor in the advancement of electric vehicle technology, offering a promising alternative to conventional internal combustion engines.

Toyota's Electric Evolution: A Green Revolution in the Works?

You may want to see also

Power Generation: EVs convert electrical energy into motion without internal combustion

Electric vehicles (EVs) have revolutionized the automotive industry by offering an eco-friendly and efficient mode of transportation. One of the key aspects that set EVs apart from traditional internal combustion engine (ICE) vehicles is their power generation and propulsion system. Unlike ICE vehicles, EVs do not rely on rods and pistons to generate power and move the vehicle forward. Instead, they utilize a different mechanism to convert electrical energy into motion.

The power generation process in EVs is based on the principles of electric motors. When an EV is driven, the battery pack supplies electrical energy to the electric motor. This motor is designed to convert electrical power into mechanical energy, which is then used to rotate the wheels and propel the vehicle. The absence of rods and pistons in this system is a significant advantage, as it eliminates the need for complex and noisy internal combustion processes.

At the heart of an EV's power generation is the electric motor, which can be either a direct current (DC) motor or an alternating current (AC) motor. These motors are highly efficient and provide instant torque, resulting in quick acceleration. When the driver engages the accelerator pedal, the motor receives electrical energy and begins to rotate, driving the wheels and moving the vehicle. This process is achieved without the need for a traditional transmission, as the motor's speed and torque can be precisely controlled.

The efficiency of EV power generation is further enhanced by the use of regenerative braking. When the driver applies the brakes, the electric motor acts as a generator, converting the vehicle's kinetic energy back into electrical energy. This energy is then stored in the battery pack, improving overall efficiency and extending the driving range. This regenerative braking system is a unique feature of EVs, allowing them to recover energy that would otherwise be lost during braking in conventional vehicles.

In summary, electric vehicles have transformed power generation and propulsion by eliminating the need for rods and pistons. Instead, they employ electric motors and regenerative braking systems to efficiently convert electrical energy into motion. This innovation has led to improved performance, reduced environmental impact, and a more sustainable approach to transportation, making EVs an increasingly popular choice for drivers worldwide.

Understanding 'Ready': Unlocking EV Potential

You may want to see also

Transmission: Gear systems in EVs transmit power, but not through piston-rod mechanisms

Electric vehicles (EVs) have revolutionized the automotive industry, offering an eco-friendly and efficient mode of transportation. One of the key components that set EVs apart from traditional internal combustion engine (ICE) vehicles is their transmission system. While ICE vehicles rely on complex mechanisms involving rods and pistons to transmit power, EVs utilize a different approach to achieve efficient power transfer.

In traditional ICE vehicles, the transmission system is a crucial component that manages the transfer of power from the engine to the wheels. It typically involves a series of gears, clutches, and a piston-rod mechanism. The piston-rod assembly is responsible for translating the reciprocating motion of the engine's pistons into rotational motion, which is then transferred to the wheels through the gear system. This mechanism is essential for controlling the vehicle's speed and torque.

However, EVs operate on a fundamentally different principle. Instead of internal combustion engines, EVs are powered by electric motors, which directly convert electrical energy into mechanical motion. The transmission in an EV is designed to optimize the power delivery from the electric motor to the wheels, ensuring smooth acceleration and efficient energy usage. Unlike ICE vehicles, EVs do not require a piston-rod mechanism to transmit power.

The gear systems in EVs are designed to handle the unique characteristics of electric motors. These motors produce high torque at low speeds, which is ideal for quick acceleration. The gear ratio in an EV transmission is carefully selected to match the motor's output to the driving conditions. This allows for a seamless and efficient power transfer, providing the driver with instant torque and a responsive driving experience.

Furthermore, the absence of a piston-rod mechanism in EVs contributes to their overall efficiency and performance. Without the need for complex reciprocating motion, EVs can achieve higher energy efficiency, reduced weight, and improved overall performance. The transmission system in an EV is often simpler and more compact, allowing for better weight distribution and a more streamlined design. This simplicity also contributes to lower maintenance requirements, making EVs a cost-effective and environmentally friendly choice for drivers.

Sparking Safety: A Guide to Electrical Fire Hazards in Cars

You may want to see also

Efficiency: Electric powertrains offer higher efficiency without the need for piston-rod assemblies

The concept of efficiency in electric powertrains is a significant advantage over traditional internal combustion engines. One of the key factors contributing to this higher efficiency is the absence of piston-rod assemblies, which are essential components in conventional engines. These assemblies, comprising pistons and rods, are responsible for converting the linear motion of the piston into rotational motion, which is then transferred to the crankshaft. However, this process involves energy losses due to friction and heat, especially in the case of reciprocating piston engines.

In electric powertrains, the power generation and transmission process is fundamentally different. Electric motors, whether AC or DC, convert electrical energy directly into mechanical energy without the need for piston-rod assemblies. This direct conversion results in a more efficient energy transfer, as there are no intermediate mechanical components to lose energy through friction and heat. The absence of pistons and rods simplifies the overall design, reduces moving parts, and minimizes the energy required to overcome friction, leading to improved overall efficiency.

The efficiency of electric powertrains is further enhanced by the ability to recover and reuse energy. Electric vehicles (EVs) can employ regenerative braking, a feature that converts the kinetic energy of the vehicle back into electrical energy, which is then stored in the battery. This process, known as energy recovery, is not possible in traditional vehicles with internal combustion engines. The energy saved during braking can be used to assist acceleration, further improving the overall efficiency and range of electric vehicles.

Additionally, the design of electric powertrains allows for a more compact and lightweight construction. Without the need for large and complex piston-rod assemblies, electric motors can be designed with a higher power-to-weight ratio, enabling EVs to achieve better performance and efficiency. This lightweight design also contributes to reduced energy consumption, as less power is required to accelerate the vehicle, further emphasizing the efficiency advantage of electric powertrains.

In summary, electric powertrains offer a more efficient approach to vehicle propulsion due to their ability to bypass the energy-intensive piston-rod assembly. The direct conversion of electrical energy to mechanical energy, coupled with energy recovery systems and lightweight designs, results in higher overall efficiency. These advantages contribute to the growing popularity of electric vehicles, as they provide a more sustainable and environmentally friendly transportation option without compromising on performance.

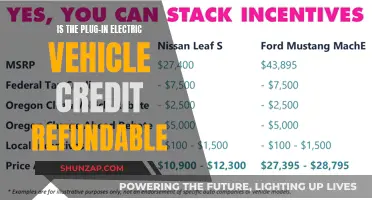

Electric Vehicle Incentives: Unraveling the Tax Conundrum

You may want to see also

Maintenance: EVs require less maintenance due to the absence of piston-rod engine components

Electric vehicles (EVs) have revolutionized the automotive industry, offering an eco-friendly and efficient mode of transportation. One of the key advantages of EVs is their lower maintenance requirements compared to traditional internal combustion engine (ICE) vehicles. This is primarily due to the absence of certain complex mechanical components, such as rods and pistons, which are integral to the operation of piston-rod engines.

In traditional ICE vehicles, the engine's operation relies on a precise interplay of rods and pistons. These components work in harmony to convert the energy from fuel into mechanical motion, which then powers the vehicle. However, this intricate system also requires regular maintenance to ensure optimal performance and longevity. The rods and pistons, being critical to the engine's function, are susceptible to wear and tear, leading to potential issues such as engine knocking, reduced power, and increased fuel consumption.

EVs, on the other hand, operate on a fundamentally different principle. They utilize electric motors powered by batteries, eliminating the need for the intricate piston-rod mechanism. This design simplification significantly reduces the number of moving parts, resulting in less frequent maintenance requirements. Without the piston-rod engine, EVs avoid the common issues associated with engine wear, such as timing belt failures, valve train problems, and cylinder head gaskets.

The maintenance of an EV typically involves checking fluid levels, such as coolant and brake fluid, and ensuring the battery is in good condition. Unlike ICE vehicles, EVs do not require oil changes, spark plug replacements, or exhaust system repairs. This reduced maintenance schedule not only saves time and money but also contributes to the overall sustainability of the vehicle, as fewer resources are needed for upkeep.

In summary, the absence of rods and pistons in electric vehicles is a significant factor in their lower maintenance needs. This design choice has led to a more efficient and environmentally friendly transportation option, offering drivers a hassle-free and cost-effective driving experience. As technology advances, EVs continue to evolve, providing an increasingly attractive alternative to traditional combustion engines.

The Birth of the First Fully Electric Car: A Revolutionary Journey

You may want to see also

Frequently asked questions

No, electric vehicles do not utilize internal combustion engines. Instead, they rely on electric motors powered by batteries or fuel cells. These motors operate without the need for rods and pistons, which are components of internal combustion engines.

Electric vehicles generate motion through the use of electric motors. These motors convert electrical energy into mechanical energy, producing torque that drives the wheels. The absence of rods and pistons allows for a more efficient and compact design, as electric motors can be smaller and lighter compared to their internal combustion counterparts.

While electric vehicles eliminate the need for rods and pistons, they still have some mechanical components. These include gears, differentials, and suspension systems, which are essential for controlling the vehicle's movement and ensuring a smooth ride. However, the overall complexity and number of moving parts are significantly reduced compared to traditional internal combustion engine vehicles.