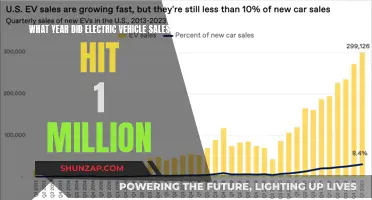

Electric vehicles (EVs) have revolutionized the automotive industry, offering a more sustainable and environmentally friendly alternative to traditional gasoline-powered cars. One of the key questions that often arises when discussing EVs is whether they have any moving parts, and if so, what materials are they made of. In this paragraph, we will explore the components of electric vehicles and specifically address whether they contain steel moving parts.

What You'll Learn

- Engine Components: Electric motors still have internal moving parts like gears and bearings

- Transmission: CVT or single-speed transmissions are common in EVs, lacking traditional gear shifts

- Drivetrain: The drive system, including the motor and wheels, operates without a traditional transmission

- Braking System: EVs use regenerative braking, reducing wear on mechanical parts

- Suspension: Advanced suspension systems in EVs offer smooth rides without traditional steel springs

Engine Components: Electric motors still have internal moving parts like gears and bearings

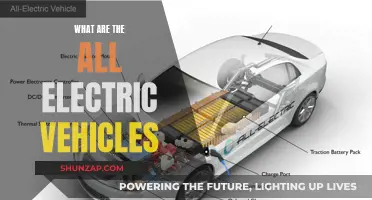

Electric vehicles, despite their reputation for being environmentally friendly and efficient, still rely on a complex network of internal moving parts to function. One of the key components that often goes unnoticed is the electric motor, which is the heart of the vehicle's propulsion system. While electric motors have evolved significantly over the years, they still require various mechanical elements to operate effectively.

At the core of an electric motor's operation are gears and bearings. These components are essential for transmitting power and ensuring smooth rotation. Gears, typically made from durable materials like steel, are used to control the speed and torque of the motor. They enable the motor to deliver the required power to the wheels while maintaining the necessary speed and acceleration. The precision and quality of these gears are crucial, as they directly impact the overall performance and longevity of the vehicle.

Bearings, another critical element, are designed to reduce friction and support the rotating parts of the motor. They allow for smooth rotation of the gears and other moving components, ensuring efficient power transmission. These bearings are often made from high-quality materials, such as steel or specialized alloys, to withstand the demanding conditions inside the motor. The choice of bearing material is vital, as it influences the motor's durability and overall performance.

The combination of gears and bearings in electric motors is a delicate balance of engineering. Manufacturers carefully select materials and designs to optimize performance and efficiency. For instance, the use of steel in gears provides strength and durability, ensuring they can handle the stresses of continuous operation. Similarly, bearings made from advanced materials offer reduced friction, improved heat dissipation, and enhanced longevity, contributing to the overall reliability of the electric vehicle.

In summary, while electric vehicles are known for their advanced technology and reduced environmental impact, they still rely on traditional engine components. Electric motors, in particular, contain essential moving parts like gears and bearings, which are crafted from materials such as steel to ensure optimal performance and durability. Understanding these engine components is crucial for appreciating the intricate workings of electric vehicles and their ability to provide efficient transportation.

Aerodynamic Design: The Secret to Electric Vehicle Efficiency

You may want to see also

Transmission: CVT or single-speed transmissions are common in EVs, lacking traditional gear shifts

Electric vehicles (EVs) have revolutionized the automotive industry, offering a more sustainable and efficient mode of transportation. One of the key differences between EVs and traditional internal combustion engine (ICE) vehicles is their transmission system. EVs often utilize Continuously Variable Transmission (CVT) or single-speed transmissions, which differ significantly from the multi-gear transmissions found in conventional cars.

CVT transmissions, also known as stepless transmissions, provide a seamless and smooth driving experience. Instead of traditional gear ratios, CVTs use a belt or chain wrapped around two variable-diameter pulleys. This design allows for an infinite number of gear ratios, enabling the EV to accelerate smoothly and efficiently. By eliminating the need for gear shifts, CVTs contribute to a quieter and more comfortable ride, as there is no abrupt change in power delivery. This type of transmission is particularly well-suited for the unique power delivery characteristics of electric motors, which provide instant torque and smooth acceleration.

Single-speed transmissions, as the name suggests, feature a single gear ratio, which is carefully designed to match the EV's performance characteristics. This approach simplifies the drivetrain and reduces the complexity of the vehicle. Single-speed EVs often have a higher top speed and better efficiency compared to multi-speed transmissions, as the gear ratio is optimized for the specific power output of the electric motor. This design choice also contributes to the overall simplicity and reliability of the EV's drivetrain.

The absence of traditional gear shifts in EVs is a direct result of the unique requirements of electric powertrains. Electric motors deliver their maximum torque from a standstill, eliminating the need for a wide range of gear ratios to match different driving conditions. CVTs and single-speed transmissions excel in managing the instant torque of electric motors, ensuring a responsive and efficient driving experience. This transmission technology is a key enabler for the smooth and linear acceleration that EVs are known for, further enhancing the overall driving pleasure.

In summary, the transmission systems in electric vehicles are designed with a focus on efficiency, simplicity, and smooth power delivery. CVT and single-speed transmissions offer a unique approach to vehicle propulsion, catering to the specific needs of electric powertrains. By eliminating traditional gear shifts, EVs provide a more comfortable and responsive driving experience, contributing to their growing popularity in the automotive market.

Unveiling the Mystery: Ice in Electric Vehicles

You may want to see also

Drivetrain: The drive system, including the motor and wheels, operates without a traditional transmission

The drivetrain of an electric vehicle (EV) is a fascinating and unique component that sets it apart from traditional internal combustion engine (ICE) vehicles. One of the most significant differences is the absence of a conventional transmission, which is a crucial element in the power delivery process. In ICE vehicles, the transmission is responsible for matching the engine's rotational speed and torque to the vehicle's speed and driving conditions. However, in electric vehicles, the drivetrain takes on a different role due to the inherent characteristics of electric motors.

Electric motors are highly efficient and provide a direct and instantaneous connection between the power source (usually a battery) and the wheels. This is made possible by the absence of a traditional transmission, which is replaced by a simpler and more compact system. The drive system in an EV typically consists of an electric motor, a reduction gear (if required), and the wheels. When the driver engages the accelerator, the battery supplies power to the motor, which then drives the wheels directly. This process is remarkably efficient, as there is no energy loss due to gear changes or complex transmission mechanics.

The simplicity of the drivetrain in electric vehicles is a result of the motor's ability to provide torque at various speeds, eliminating the need for multiple gear ratios. This is in contrast to ICE vehicles, where transmissions are designed to handle a wide range of engine speeds and provide the necessary torque for different driving conditions. In EVs, the motor's characteristics allow for a more direct and efficient power transfer, ensuring that the wheels receive the required torque for acceleration and maintaining speed.

Furthermore, the absence of a traditional transmission contributes to the overall reliability and longevity of electric vehicles. With fewer moving parts and simpler mechanics, the risk of mechanical failures and the need for frequent maintenance are significantly reduced. This simplicity also allows for more efficient cooling systems, as there are no complex transmission fluids or lubricants to manage. As a result, electric vehicles often have longer lifespans and require less maintenance compared to their ICE counterparts.

In summary, the drivetrain of an electric vehicle is a remarkable engineering achievement, showcasing the benefits of electric power over traditional combustion engines. The absence of a conventional transmission enables a more efficient, direct, and reliable power delivery system, contributing to the overall performance and longevity of EVs. This unique feature is a key factor in the growing popularity and success of electric vehicles in the automotive industry.

Powering the Engine: The Secret to Vehicle Electricity

You may want to see also

Braking System: EVs use regenerative braking, reducing wear on mechanical parts

The braking system in electric vehicles (EVs) is a fascinating aspect of their design, offering a unique approach to deceleration and stopping. One of the key advantages of EVs is their use of regenerative braking, which significantly reduces wear and tear on mechanical components compared to traditional internal combustion engine vehicles.

Regenerative braking works by converting the kinetic energy of the vehicle's motion into electrical energy, which is then stored in the battery. This process is achieved through the interaction of the electric motor and the braking system. When the driver applies the brakes, the electric motor acts as a generator, slowing down the vehicle's wheels and, consequently, the entire car. The energy generated during this process is fed back into the battery, recharging it and reducing the need for traditional friction-based braking systems.

This innovative braking mechanism has several benefits. Firstly, it eliminates the need for a physical connection between the wheels and the brakes, which is typically achieved through steel rotors and pads in conventional vehicles. Instead, EVs rely on the electric motor's ability to provide braking force without the use of mechanical wear items. This not only reduces the number of moving parts but also minimizes the risk of brake fade, a common issue with traditional braking systems, especially during prolonged or aggressive braking.

The absence of steel rotors and pads in EVs contributes to their overall efficiency and longevity. Without the constant friction and heat generated by traditional brakes, the braking system in EVs experiences less wear, resulting in longer component lifespans. This not only reduces maintenance costs for EV owners but also contributes to the overall reliability and performance of the vehicle.

Furthermore, regenerative braking provides a more seamless and responsive driving experience. The instant feedback and control offered by this system allow for precise deceleration, enhancing the overall driving dynamics of EVs. This technology is a testament to the continuous innovation in the automotive industry, aiming to improve efficiency, performance, and the overall driving experience.

EV Battery End-of-Life: Recycling, Disposal, and Second Life Potential

You may want to see also

Suspension: Advanced suspension systems in EVs offer smooth rides without traditional steel springs

The evolution of electric vehicles (EVs) has brought about significant advancements in various components, and one of the most notable improvements is in the suspension system. Traditional internal combustion engine vehicles often rely on steel springs for suspension, which provide a certain level of comfort and control. However, electric vehicles have embraced innovative suspension technologies that offer a smoother and more refined driving experience without the need for conventional steel springs.

Advanced suspension systems in EVs are designed to provide a more comfortable and controlled ride, especially on diverse road conditions. These systems often utilize a combination of electronic controls and innovative materials to achieve their goals. One of the key advantages is the ability to adjust the suspension in real-time, responding to road inputs and driver preferences. This dynamic adjustment ensures that the vehicle maintains optimal contact with the road, enhancing stability and handling.

In the absence of traditional steel springs, EVs often employ air suspension or electronic suspension systems. Air suspension uses compressed air springs that can be adjusted independently for each wheel, allowing for precise control over ride height and damping. This setup enables the vehicle to adapt to varying loads and road conditions, providing a consistently smooth ride. Electronic suspension systems, on the other hand, use hydraulic or electromagnetic actuators to adjust the suspension, offering similar benefits with the added advantage of rapid response times.

The benefits of these advanced suspension systems are twofold. Firstly, they contribute to a more comfortable driving experience by reducing the impact of bumps and road imperfections. This is particularly important for long-distance travel, where a smooth ride can significantly enhance passenger comfort. Secondly, these systems improve handling and stability, especially during cornering and rapid maneuvers. By maintaining optimal tire contact with the road, EVs can achieve better performance and responsiveness, appealing to drivers who value dynamic driving characteristics.

Furthermore, the absence of traditional steel springs in EVs allows for more efficient packaging of other components. The space previously occupied by the spring and shock absorber can be utilized for additional batteries or other systems, contributing to the overall efficiency and range of the vehicle. This efficient use of space is a significant advantage in the competitive automotive market, where every inch of space matters. As such, the advanced suspension systems in electric vehicles not only provide a smoother ride but also contribute to the overall performance and efficiency of these innovative vehicles.

India's Slow Embrace of Electric Cars: Unraveling the Mystery

You may want to see also

Frequently asked questions

While electric vehicles have fewer moving parts compared to traditional internal combustion engine (ICE) cars, they still utilize some steel components. For example, EVs have electric motors with steel gears and bearings to transmit power, and these parts are crucial for the vehicle's performance and efficiency.

Yes, the drivetrain of an electric vehicle often includes steel components such as gears, differentials, and transmission systems. These parts are designed to handle the power and torque generated by the electric motor and ensure efficient power transfer to the wheels.

Absolutely! Electric vehicles typically have advanced suspension systems, and steel is commonly used in the form of suspension arms, control arms, and springs. These components provide a smooth ride, improve handling, and ensure the vehicle's stability on the road.

EVs do have some moving parts, but they are significantly reduced compared to conventional cars. Besides the steel components mentioned above, electric vehicles also have drive units with rotating parts, such as pulleys and belts, which are used in some designs to transfer power from the motor to the wheels. However, the overall complexity and number of moving parts are much lower in electric cars.