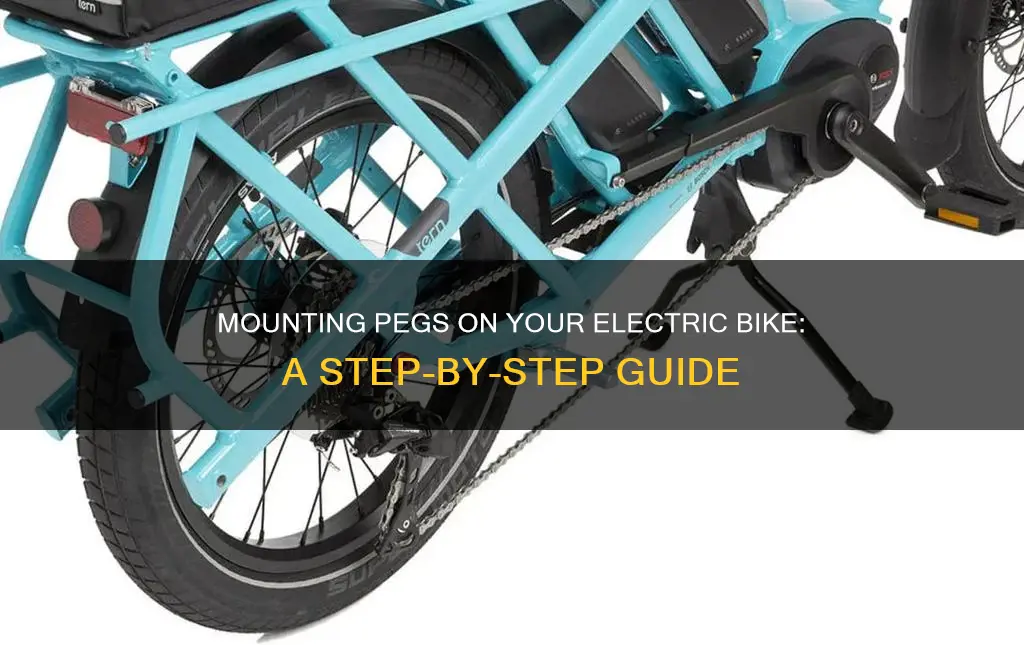

Mounting pegs on an electric bike can be a challenging task, but it's not impossible. The process involves careful consideration of safety and mechanical functions to ensure that feet and components don't interfere with the wheel, spokes, chain or derailleur. It's also important to make sure that the mounting hardware is removable and won't damage any frame or paint components. One option for mounting pegs is to use angle iron and weld peg bolts as bosses, but this requires cutting, bending, and drilling to match the frame. Another option is to purchase bolt-on foot pegs that are compatible with specific electric bike models.

| Characteristics | Values |

|---|---|

| Safety | Feet or components must not become entangled or interfere with the wheel, spokes, chain or derailleur |

| Functionality | Braking must function well |

| Hardware | Must be removable and not damage any frame or paint components |

| Mounting spot | The threaded rack and fender bosses can be used as "holding" points |

| Mounting process | Cut and bend angle iron to match the frame bend, weld peg bolts as bosses, weld and ground the mounts, drill holes to match the frame bosses |

| Mounting equipment | Angle iron, peg bolts, rubber insulators, screws, clamps |

What You'll Learn

How to attach foot pegs to an electric bike's chainstay

Attaching foot pegs to an electric bike's chainstay is a relatively straightforward process, but it's important to keep safety and mechanical functions in mind. Here's a step-by-step guide on how to do it:

- Find a suitable mounting spot for the brackets. This can be tricky, as future e-bikes will likely have designated mounting tabs for pegs. For now, consider using the threaded rack and fender bosses as "holding" points, ensuring that the bulk of the rider's weight is supported by the lower frame.

- Cut and bend two 7" pieces of 1/2" angle iron to match the frame bend of your electric bike.

- Weld four 10mm peg bolts as bosses to the angle iron.

- Weld and grind the mounts to secure them in place.

- Drill holes in the mounts to match the frame bosses.

- Use longer hardened 5mm screws to hold down the mounting brackets securely.

- Consider adding rubber insulators to the underside of the mounting brackets to protect the bike's frame and paint.

- Test the foot pegs with a lightweight rider (around 90lb) to ensure they can withstand downward pressure without bending the mounts.

- If necessary, add a clamp to the front of the foot pegs for additional stability and to prevent excessive downward pressure on the mounts.

Remember to take into account the weight limits of your electric bike, as well as the motor, controller, and drive train capabilities. It's crucial to ensure that the foot pegs do not interfere with the wheel, spokes, chain, or derailleur, and that braking remains fully functional.

Crafting Powerful Electric Bikes: Secrets to Success

You may want to see also

How to cut and bend angle iron to match the frame bend

To cut and bend angle iron to match the frame bend, you can follow these steps:

- Securely clamp one end of the angle iron in a bender or vise, leaving the portion you want to bend exposed. Ensure that the angle iron is properly aligned with the bending line.

- Gradually apply even pressure to the exposed portion of the angle iron, using the bender's handle or other means, to bend it to the desired angle. Be cautious not to apply excessive force to prevent cracking or deformation.

- If you are using a heating torch, hold the flame 1/4 to 1/2 inch away from the line you marked on the angle iron.

- To achieve a precise bend, you can determine the angle, for example, 30 degrees, and then draw a line where you want to bend. Cut a 15-degree vee on each side of the line to ensure that both sides are equal when closed for welding.

- If you are unable to bend the angle iron with the above methods, you may need to cut the angle iron. Use an angle grinder to cut along the inside 90-degree angle, cutting in about 1/16th of an inch. Preheat the angle iron with an oxy/acetylene torch if you have one, and then bend it with a hammer.

These steps should allow you to cut and bend angle iron to match the frame bend of your electric bike.

Electric Bike Revolution: Installing Rear Wheels Easily

You may want to see also

How to weld peg bolts and mount them

To weld peg bolts and mount them on an electric bike, you will need to follow these steps:

- Cut a portion of the left angle away from a 7" piece of 1/2" angle iron.

- Cut and bend the pieces to match the frame bend of your electric bike.

- Weld four 10mm peg bolts as bosses.

- Weld and ground the mounts.

- Drill holes to match the frame bosses.

- Use longer hardened 5mm screws to hold down the mounting brackets.

- Attach rubber insulators on the underside of the mounting bracket.

- Consider the weight limits of your bike, motor and drive train components.

- Ensure that the hardware is removable and does not damage any frame or paint components.

- Test the setup to ensure that it is safe and functional, paying attention to safety and mechanical functions.

Generating Electricity with a Bike: A Guide to Pedal Power

You may want to see also

How to drill holes to match the frame bosses

To drill holes to match the frame bosses, you will need to cut and bend the angle iron to match the frame bend of your electric bike. Once you have done this, weld four 10mm peg bolts as bosses. You can then weld and grind the mounts before drilling holes to match the frame bosses.

It is important to consider safety and mechanical functions when drilling holes to match the frame bosses. Ensure that the feet or components cannot become entangled or interfere with the wheel, spokes, chain or derailleur. Braking must also function well. The hardware must be removable and should not damage any frame or paint components.

A Simple Guide to Installing Fenders on Your Electra Townie

You may want to see also

How to stabilise foot pegs to prevent bending

To stabilise foot pegs on an electric bike and prevent bending, you could add a clamp to the front to prevent too much downward pressure on the peg from potentially bending the mounts outward. This will also help to stabilise the foot peg. You could also try adding braces to keep the main section stationary and vertical.

If you want to prevent the pins from bending, you could try heat-treating them to make them harder. Heat them up to red hot and then put them in water or oil.

It's worth noting that some foot pegs are designed to be folded away when not in use, so they may not need to be stabilised in the same way as those that are permanently fixed.

Electric Bike Lock Installation: A Step-by-Step Guide

You may want to see also

Frequently asked questions

You can mount pegs to your electric bike by using a secure bolt-on mount to attach them to the chainstay.

You should consider the weight limits of the bike, motor and drive train components. You should also ensure that the hardware is removable and does not damage any frame or paint components.

It is important to ensure that feet or components do not become entangled or interfere with the wheel, spokes, chain or derailleur. Braking must also function well.

One alternative method is to use the threaded rack and fender bosses as "holding" points while placing the bulk of the rider's downward weight on the lower frame.