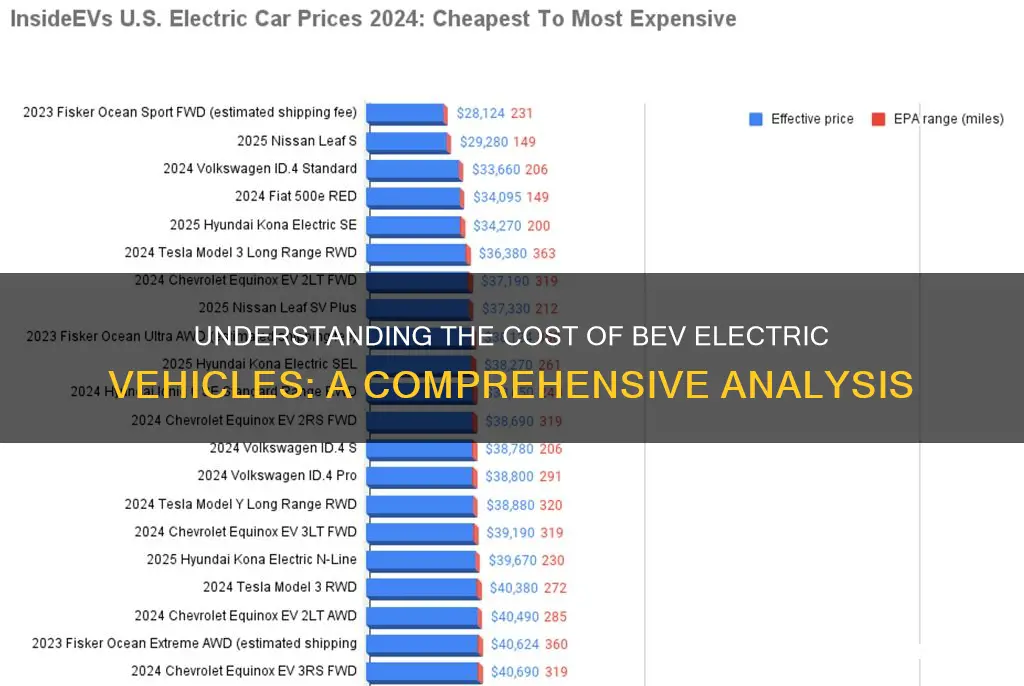

The cost of electric vehicles (EVs) is a topic of growing interest as the automotive industry shifts towards sustainable transportation. One question that often arises is whether electric vehicles are expensive to own and operate. This paragraph aims to explore this question by examining the factors that contribute to the perceived high cost of EVs, including initial purchase prices, battery technology advancements, and the potential for long-term savings through reduced fuel and maintenance expenses. It will also touch on government incentives and the overall trend of decreasing EV prices as technology matures, making electric vehicles more accessible and affordable for a wider range of consumers.

What You'll Learn

- Battery Technology: High-capacity batteries drive up costs

- Rare Earth Metals: Limited supply increases vehicle price

- Production Costs: Manufacturing electric vehicles is more expensive

- Research & Development: Innovation drives up vehicle prices

- Market Demand: Limited supply and high demand lead to higher prices

Battery Technology: High-capacity batteries drive up costs

The high cost of electric vehicles (EVs), particularly battery electric vehicles (BEVs), is often attributed to the advanced battery technology they employ. At the heart of this expense is the development and production of high-capacity batteries, which are essential for BEVs to achieve extended driving ranges. These batteries are designed to store a significant amount of energy, allowing EVs to travel longer distances without the need for frequent charging. However, the pursuit of higher energy density and improved performance comes at a cost.

One of the primary factors contributing to the high cost of BEV batteries is the use of advanced materials. Traditional lead-acid or nickel-cadmium batteries have given way to more sophisticated chemistries, such as lithium-ion (Li-ion). Li-ion batteries offer several advantages, including higher energy density, longer cycle life, and improved safety compared to their predecessors. However, the materials used in Li-ion batteries, such as lithium, cobalt, nickel, and manganese, are rare and expensive. The extraction and processing of these materials involve complex and costly processes, driving up the overall battery cost.

Another aspect that influences battery cost is the manufacturing process. High-capacity batteries require precise engineering and intricate manufacturing techniques. The production involves multiple steps, including cell assembly, electrode coating, and electroplating, which demand specialized equipment and skilled labor. The complexity of the manufacturing process, coupled with the need for high-quality control, contributes to the higher cost of BEV batteries. Additionally, the scale of production for BEVs is relatively small compared to traditional automotive markets, which can further increase per-unit costs.

Research and development (R&D) efforts play a crucial role in battery technology advancements, and these investments are reflected in the price of BEVs. Companies are constantly striving to improve battery performance, energy density, and charging capabilities. This involves extensive R&D to optimize battery chemistry, enhance safety features, and develop more efficient manufacturing processes. The continuous innovation and technological breakthroughs in battery technology drive up the cost of BEVs, as manufacturers aim to provide the latest and most advanced features to consumers.

Despite the higher initial cost, it is essential to recognize that battery technology is rapidly evolving. As research continues and production scales, economies of scale can be achieved, potentially reducing the cost of BEV batteries over time. Additionally, government incentives and subsidies in many regions aim to promote the adoption of electric vehicles, which can help offset the higher purchase price. While the cost of BEVs remains a significant consideration for consumers, ongoing advancements in battery technology are paving the way for more affordable and sustainable electric transportation in the future.

Electric Vehicle Market: Surplus or Shortage?

You may want to see also

Rare Earth Metals: Limited supply increases vehicle price

The cost of electric vehicles (EVs), particularly those powered by battery-electric (BEV) technology, is often attributed to various factors, and one of the most significant is the limited supply of rare earth metals. These metals, including neodymium, dysprosium, and praseodymium, are essential components in the production of powerful permanent magnets used in BEVs. The scarcity of these metals directly influences the overall price of EVs, making them more expensive compared to traditional internal combustion engine (ICE) vehicles.

The demand for rare earth metals has surged with the growing popularity of EVs, as these metals are crucial for the high-performance motors and advanced battery systems that power BEVs. However, the supply of these metals is constrained by their limited availability in the Earth's crust and the complex, energy-intensive processes required to extract and refine them. As a result, the supply chain for rare earth metals is vulnerable to disruptions, which can lead to price volatility and, consequently, higher vehicle costs.

The limited supply of rare earth metals is a critical issue because these metals are not easily substituted. They are essential for the unique magnetic properties required in BEVs, and their absence would significantly impact the performance and efficiency of electric motors. This lack of substitutability means that even a slight reduction in the supply of these metals can have a substantial effect on the production costs of EVs, ultimately leading to higher prices for consumers.

Furthermore, the environmental and ethical concerns associated with mining and processing rare earth metals add another layer of complexity to the issue. The extraction processes can be environmentally damaging, and the sourcing of these metals often involves questionable labor practices in certain regions. As a result, there is a growing push for more sustainable and ethical sourcing methods, which could potentially increase the cost of production.

In summary, the limited supply of rare earth metals is a significant contributor to the higher price tag of BEV electric vehicles. This scarcity drives up production costs, and the lack of readily available substitutes further exacerbates the issue. Addressing the supply chain challenges and exploring more sustainable practices in the extraction and processing of these metals are essential steps towards making EVs more affordable and accessible to a wider market.

Fire Safety for Electric Vehicles: Choosing the Right Extinguisher

You may want to see also

Production Costs: Manufacturing electric vehicles is more expensive

The production of electric vehicles (EVs) is indeed more expensive compared to traditional internal combustion engine (ICE) vehicles, and this is a significant factor in the higher upfront cost of EVs. One of the primary reasons for this is the complexity of the EV's battery pack and the advanced technology it incorporates. These battery systems are made up of numerous cells, each containing intricate components such as cathodes, anodes, electrolytes, and sophisticated cooling systems. Manufacturing these components requires specialized equipment and processes, often involving high-precision machinery and skilled labor. As a result, the cost of producing a single battery cell can be substantial, and when scaled up for an entire battery pack, it contributes significantly to the overall production expense.

Another aspect contributing to the higher production costs is the use of rare earth metals and other specialized materials. Electric vehicle batteries often contain materials like lithium, cobalt, and nickel, which are extracted and processed from specific mineral sources. The extraction and purification of these materials can be energy-intensive and environmentally challenging, driving up the cost of raw materials. Additionally, the demand for these rare earth metals is increasing as the EV market grows, further impacting their availability and price.

Furthermore, the manufacturing process itself is more intricate and resource-intensive. EVs require advanced assembly lines that integrate various components, including the battery pack, electric motor, power electronics, and sophisticated control systems. These components must be precisely engineered and assembled, often involving multiple stages of production. The labor-intensive nature of this process, combined with the need for specialized equipment and quality control measures, contributes to higher production costs.

The higher production costs of EVs are also influenced by the need for research and development (R&D) investments. Automakers invest significantly in R&D to improve battery technology, enhance performance, and extend the range of their electric vehicles. These R&D efforts are crucial for staying competitive in the market and attracting environmentally conscious consumers. However, the initial R&D costs are often recouped through higher production expenses, which are then passed on to the consumer.

Despite the higher production costs, it is essential to recognize that electric vehicles offer long-term cost savings. The reduced need for frequent engine repairs and maintenance, as well as the lower cost of electricity compared to gasoline, can offset the initial investment over the vehicle's lifetime. Additionally, government incentives and subsidies in many regions aim to promote EV adoption, making them more affordable for consumers. While the production of electric vehicles is currently more expensive, ongoing technological advancements and economies of scale are expected to drive down costs, making EVs more accessible and cost-effective in the future.

Vehicle Chassis: Conducting the Electrical Circuit Path

You may want to see also

Research & Development: Innovation drives up vehicle prices

The cost of electric vehicles (EVs), particularly those powered by battery-electric (BEV) technology, has often been a topic of discussion and concern for potential buyers. While the initial perception was that EVs were expensive due to their relatively new market position, recent trends indicate that innovation in research and development (R&D) is a significant driver of rising vehicle prices. This is particularly true for BEVs, which are at the forefront of the EV revolution.

BEV technology is rapidly evolving, and the continuous pursuit of innovation has led to several advancements that contribute to higher price tags. One of the primary factors is the development of more efficient and powerful batteries. Modern BEVs are equipped with advanced lithium-ion batteries that offer higher energy density, allowing for increased range and improved performance. However, the production of these advanced batteries requires sophisticated manufacturing processes and rare earth materials, which are costly. As a result, the overall cost of the vehicle increases to accommodate these technological upgrades.

Additionally, R&D efforts in the automotive industry have led to the integration of cutting-edge features and systems in BEVs. These include advanced driver-assistance systems (ADAS), autonomous driving capabilities, and sophisticated infotainment systems. Each of these features requires complex software, sensors, and hardware, which contribute to the higher price points. For instance, the implementation of autonomous driving technology involves a network of cameras, radar, and lidar, all of which add to the vehicle's cost.

Furthermore, the focus on sustainability and environmental impact has driven innovation in BEVs. Manufacturers are investing in R&D to create more eco-friendly materials and processes, such as using recycled materials for battery production and implementing energy-efficient systems. While these initiatives are crucial for the long-term viability of the industry, they also contribute to the higher initial costs of BEVs. As the industry continues to evolve, it is essential to strike a balance between innovation and affordability to make electric vehicles accessible to a broader market.

In summary, the rising prices of BEVs can be attributed to the continuous innovation and development in R&D. From advanced battery technology to autonomous driving features, each improvement contributes to the overall cost. However, as the industry matures, it is expected that these innovations will become more accessible and affordable, making electric vehicles a more viable and cost-effective option for consumers.

Electric Vehicles: Powering Progress Without Neet

You may want to see also

Market Demand: Limited supply and high demand lead to higher prices

The concept of 'BEV' (Battery Electric Vehicle) being expensive is often associated with the high upfront cost of these vehicles, which can be a significant barrier to entry for many potential buyers. This perception is partly due to the advanced technology and materials used in BEVs, which contribute to their higher production costs compared to traditional internal combustion engine (ICE) vehicles. However, the expense of BEVs is not solely determined by their manufacturing process; it's also closely tied to market dynamics, particularly the interplay between supply and demand.

In the current market, BEVs are experiencing a unique set of circumstances that influence their pricing. Firstly, the supply side is constrained. The production of electric vehicles, especially those with advanced battery technology, is a complex process that requires specialized equipment and a steady supply of raw materials. These factors can lead to production bottlenecks, especially when demand spikes. As a result, manufacturers often face challenges in meeting the growing demand for BEVs, which in turn can drive up prices.

On the demand side, the story is equally compelling. The popularity of BEVs has been on the rise due to increasing environmental concerns, government incentives, and consumer awareness about the benefits of electric mobility. This surge in demand has outpaced the current supply capabilities, creating a situation where the limited availability of BEVs becomes a selling point rather than a hindrance. As a result, manufacturers can set higher prices, knowing that consumers are willing to pay more for these vehicles.

The limited supply and high demand dynamic have several implications. Firstly, it creates a sense of exclusivity and desirability around BEVs. This exclusivity can lead to a premium pricing strategy, where manufacturers can charge a higher price without significantly impacting sales. Secondly, it encourages innovation and investment in the electric vehicle sector. As the demand for BEVs grows, so does the need for improved production techniques, more efficient battery technology, and a more robust supply chain, all of which contribute to the long-term sustainability and cost-effectiveness of the industry.

In summary, the high cost of BEVs is not just a result of production expenses but also a consequence of market forces. Limited supply and high demand create a powerful incentive for manufacturers to maintain or increase prices, ensuring that BEVs remain a desirable and exclusive choice for environmentally conscious consumers. This market dynamics also drive innovation and investment, which are crucial for the continued growth and accessibility of electric vehicles in the long term.

Exploring the World of Battery-Powered Cars: An In-Depth Guide

You may want to see also

Frequently asked questions

While the initial purchase price of a BEV might seem expensive compared to traditional gasoline vehicles, it's important to consider the long-term savings. BEVs have lower running costs due to reduced maintenance needs and cheaper electricity compared to gasoline. Over time, this can offset the higher upfront cost.

Battery technology has advanced significantly, and modern BEVs are designed to last for many years without major battery issues. Some manufacturers offer comprehensive battery warranties, ensuring peace of mind. Additionally, used BEVs often retain a significant portion of their battery health, making them a cost-effective choice.

Charging a BEV is generally more affordable than refueling a gasoline car. Electricity prices vary, but overnight charging at home is often the most economical option. Public charging stations, while sometimes pricier, are becoming more widespread and offer various pricing models to cater to different needs.

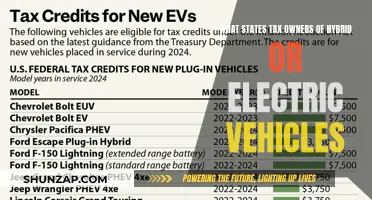

Many governments worldwide offer incentives to promote electric vehicle adoption. These can include tax credits, rebates, or grants that reduce the overall cost of purchasing a BEV. Researching local incentives can significantly lower the financial barrier to owning an electric car.