The New York State (NYS) inspection program for electric vehicles (EVs) is a crucial aspect of ensuring the safety and reliability of these innovative vehicles on the road. This inspection process is designed to verify that EVs meet specific standards and regulations, covering various components such as battery systems, charging ports, and electrical wiring. By implementing these inspections, NYS aims to promote the widespread adoption of electric vehicles while maintaining high safety standards, addressing potential concerns related to battery performance, charging infrastructure, and overall vehicle integrity. Understanding the details of this inspection process is essential for EV owners and enthusiasts, as it highlights the state's commitment to a sustainable future and the importance of regular maintenance in the electric vehicle ecosystem.

What You'll Learn

- Battery Safety: Inspecting EV batteries for overheating and fire risks

- Charging Systems: Testing charging ports and cables for functionality and safety

- Electrical Wiring: Checking wiring for corrosion, damage, and proper insulation

- Voltage Regulation: Ensuring the vehicle's electrical system maintains stable voltage levels

- Emissions Testing: Measuring EV emissions to comply with state regulations

Battery Safety: Inspecting EV batteries for overheating and fire risks

Battery safety is a critical aspect of electric vehicle (EV) inspections, especially as the number of EVs on the road continues to grow. One of the primary concerns with EV batteries is the risk of overheating and potential fire hazards. These risks are primarily associated with lithium-ion batteries, which are commonly used in EVs due to their high energy density and relatively low cost. However, the potential for thermal runaway, a self-perpetuating chain reaction that can lead to fires, is a significant issue that needs to be addressed during inspections.

During an inspection, technicians should look for any signs of damage to the battery pack, including visible punctures, cracks, or corrosion. These issues can compromise the integrity of the battery and increase the risk of overheating. Additionally, checking the battery's temperature is essential. Modern EVs are equipped with sophisticated temperature monitoring systems, but visual inspection of the battery's cooling system and its surrounding areas can provide valuable insights. Technicians should ensure that the cooling fans are operational and that there is no excessive heat buildup in the battery compartment.

Another critical aspect of battery safety inspection is the assessment of the battery management system (BMS). The BMS is responsible for monitoring and controlling the battery's performance, including temperature regulation. Technicians should verify that the BMS is functioning correctly and that it is capable of preventing overcharging, over-discharging, and excessive current flow, all of which can contribute to overheating and potential fire risks. A well-maintained and calibrated BMS is crucial for ensuring the long-term safety and reliability of the EV battery.

In addition to these visual and system-level inspections, technicians should also consider the environmental conditions in which the EV is used. Extreme temperatures, both hot and cold, can stress the battery and impact its performance and safety. Inspectors should advise EV owners on proper charging and parking practices to minimize the risk of overheating, especially in hot climates. This may include recommendations for using shade, avoiding direct sunlight, and ensuring proper ventilation around the battery compartment.

Finally, regular maintenance and monitoring of the EV battery are essential. This includes keeping the battery clean and free from debris, especially in the battery compartment, and ensuring that all connections are secure and free from corrosion. By following these inspection and maintenance protocols, technicians can help mitigate the risks associated with overheating and fire hazards in EV batteries, contributing to the overall safety and longevity of these vehicles.

Boosting EV Efficiency: Tips for Optimal Battery Performance

You may want to see also

Charging Systems: Testing charging ports and cables for functionality and safety

When it comes to electric vehicles, ensuring the charging system is in top-notch condition is crucial for both performance and safety. The New York State (NYS) inspection guidelines for electric vehicles emphasize the importance of thoroughly testing charging ports and cables to identify any potential issues. Here's a detailed breakdown of how to approach this aspect of the inspection:

Charging Port Functionality:

- Visual Inspection: Start by examining the charging port for any visible damage, corrosion, or debris. Check for loose connections or damaged ports that might hinder proper contact with the charging cable. Look for any signs of wear and tear, especially around the port's opening and sealing mechanisms.

- Port Accessibility: Ensure that the charging port is easily accessible and not obstructed by any parts or accessories. Proper accessibility is essential for quick and safe charging.

- Range and Compatibility: Verify that the charging port supports the vehicle's charging range and compatibility. Different electric vehicles may have specific charging requirements, and the port should be able to accommodate the appropriate charging connector.

Cable Testing:

- Cable Integrity: Inspect the charging cable for any physical damage, such as cuts, tears, or exposed wires. Check for signs of overheating, which could be indicated by discolored insulation or burnt smells. Ensure that the cable's length is sufficient to reach the charging station without excessive strain.

- Functionality: Test the cable's functionality by attempting to charge the vehicle. Ensure that the cable makes a secure connection with the charging port and that the charging process initiates without any errors or warnings.

- Safety Mechanisms: Modern electric vehicles often incorporate safety features like automatic disconnection during overcurrent or overvoltage conditions. Test these mechanisms by simulating extreme charging scenarios and verifying that the system responds accordingly to prevent damage.

Safety Considerations:

- Grounding and Bonding: Check the charging system's grounding and bonding connections to ensure they are secure and properly insulated. Proper grounding is essential for electrical safety and can prevent electrical shocks or short circuits.

- Insulation and Protection: Inspect the charging cable's insulation to ensure it is intact and free from damage. Verify that the cable's protective covering is not compromised, as this can lead to electrical hazards.

- Overcurrent and Overvoltage Protection: Test the vehicle's charging system for overcurrent and overvoltage protection. These protections are vital to prevent damage to the vehicle and the charging infrastructure.

During the NYS inspection, technicians should pay close attention to these charging system components, as they directly impact the vehicle's usability and safety. A comprehensive test of the charging ports and cables will help identify potential issues, ensuring that electric vehicle owners can charge their vehicles safely and efficiently.

Unlocking EV Affordability: Strategies for Developing Nations

You may want to see also

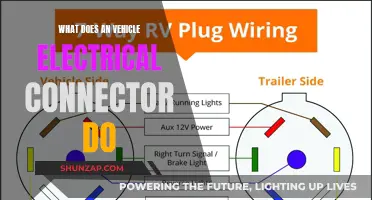

Electrical Wiring: Checking wiring for corrosion, damage, and proper insulation

When it comes to inspecting the electrical wiring of electric vehicles in New York, a thorough examination is crucial to ensure the safety and reliability of the vehicle's power system. This inspection process involves a detailed assessment of the wiring for any signs of corrosion, damage, or improper insulation. Here's a step-by-step guide to understanding this critical aspect of the inspection:

Corrosion Inspection:

Start by visually inspecting the wiring harnesses and connections for any signs of corrosion. Corrosion can occur due to exposure to moisture, salt, or other contaminants, especially in areas where the vehicle might come into contact with road salt during winter. Look for discolored or oxidized wiring, particularly around terminals and connectors. Use a magnifying glass or flashlight to examine small areas and ensure that corrosion is not present. If corrosion is detected, it may indicate a compromised connection or potential safety hazard.

Damage Assessment:

Check the wiring for any physical damage, including cuts, burns, or frays. Inspect the wiring harnesses for any visible signs of damage, especially in areas that might be prone to impact or vibration during the vehicle's operation. Look for melted insulation, exposed wires, or any signs of heat damage. These issues can lead to short circuits or complete wiring failure, posing significant risks. Ensure that all wiring is securely routed and protected from potential damage sources.

Insulation Verification:

Proper insulation is essential to prevent electrical shorts and ensure the safe operation of the vehicle. Inspect the insulation of the wiring to ensure it is intact and not damaged. Check for any exposed conductors or frayed insulation, which could lead to electrical hazards. The insulation should be intact and not show signs of wear or degradation. Pay attention to areas where wiring passes through panels or under the dashboard, as these spots might require additional insulation to protect against mechanical damage.

During the inspection, it is crucial to use the right tools, such as a multimeter, to test the continuity and resistance of the wiring. This ensures that the wiring is intact and functioning correctly. Additionally, documenting the condition of the wiring and any issues found is essential for creating a comprehensive inspection report.

By carefully examining the electrical wiring for corrosion, damage, and proper insulation, inspectors can identify potential issues that may affect the vehicle's performance and safety. This process is a vital part of the NYS inspection process for electric vehicles, ensuring that the power system remains reliable and secure.

Electric Ride Safety: Age-Appropriate Choices for Kids

You may want to see also

Voltage Regulation: Ensuring the vehicle's electrical system maintains stable voltage levels

Voltage regulation is a critical aspect of ensuring the reliability and performance of an electric vehicle's (EV) electrical system. It involves maintaining stable voltage levels across the entire electrical network, from the battery to the various components and accessories. This is essential for the efficient operation of the EV and to prevent potential issues that could arise from voltage fluctuations.

In an EV, the electrical system is designed to operate within a specific voltage range, typically between 300 and 450 volts for high-voltage systems. Any deviation from this range can impact the performance and safety of the vehicle. For instance, a drop in voltage can lead to reduced power output, affecting acceleration and overall driving experience. Conversely, a voltage spike can cause damage to sensitive electronic components, such as motors, inverters, and control units.

To achieve voltage regulation, EVs employ various techniques and components. One of the primary methods is the use of voltage regulators, which are electronic devices designed to maintain a constant output voltage regardless of changes in input or load. These regulators monitor the electrical system's voltage and adjust it accordingly to ensure stability. They can either step up or step down the voltage as needed, making them crucial for managing the electrical load and ensuring consistent performance.

Another important aspect of voltage regulation is the design of the electrical architecture. Engineers carefully plan the layout of the wiring, fuses, and other electrical components to minimize voltage drops and ensure efficient power distribution. This includes using thicker wires for high-current paths and implementing appropriate fuses to protect against overcurrent situations, which can cause voltage fluctuations.

During the NYS inspection process, technicians will assess the vehicle's voltage regulation capabilities. They will measure voltage levels at different points in the electrical system and check for any deviations from the expected range. This inspection helps identify potential issues, such as faulty voltage regulators, poor wiring connections, or excessive electrical load, which could impact the vehicle's performance and safety. By addressing these concerns, EV owners can ensure their vehicles meet the required standards and operate reliably on the road.

Unraveling the Mystery: The Brain Behind Vehicle Electrical Systems

You may want to see also

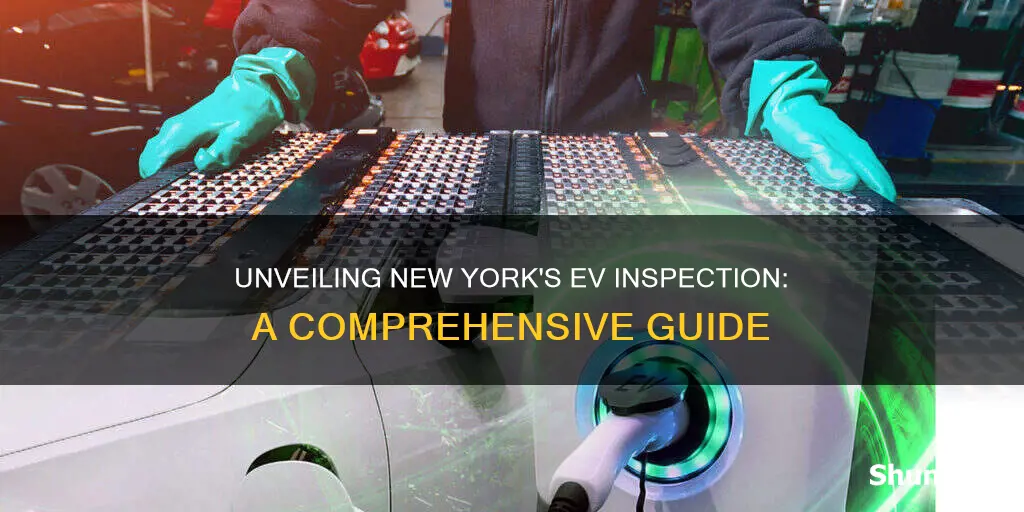

Emissions Testing: Measuring EV emissions to comply with state regulations

Emissions testing for electric vehicles (EVs) is a critical process to ensure that these vehicles meet the environmental standards set by the state of New York. The primary goal is to measure and verify the emissions of EVs, which, unlike traditional internal combustion engine vehicles, produce zero tailpipe emissions. However, the state has specific regulations to address the potential environmental impact of EVs, particularly during manufacturing and the use of materials in their construction.

The testing process involves a series of steps to evaluate the emissions of EVs. Firstly, the vehicle's emissions are measured in a controlled environment, often using specialized equipment that can detect and quantify various pollutants. This includes measuring the levels of volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter (PM) that may be emitted during the manufacturing process or due to the degradation of materials over time. The testing is designed to simulate real-world conditions, ensuring that the results are representative of the vehicle's performance in everyday use.

New York's regulations require that EVs undergo a comprehensive emissions test, which includes both laboratory and on-road testing. During laboratory testing, the vehicle's emissions are measured while it is stationary, allowing for the evaluation of the vehicle's electrical components and any potential emissions from the charging system. On-road testing, on the other hand, involves driving the EV on a closed course or a specific route to measure emissions under various driving conditions. This dual-testing approach ensures a comprehensive assessment of the vehicle's emissions performance.

The data collected from these tests is crucial for compliance with state regulations. It helps determine whether the EV meets the required emissions standards, which are designed to minimize the environmental impact of vehicle manufacturing and operation. For instance, the state may set limits on the amount of VOCs or NOx that can be emitted during the manufacturing process, ensuring that the production of EVs does not contribute significantly to air pollution. Additionally, the testing can identify any potential issues or deviations from the expected emissions levels, allowing for necessary adjustments or recalls to ensure compliance.

In summary, emissions testing for EVs in New York is a rigorous process that aims to verify the environmental friendliness of these vehicles. By measuring and evaluating emissions during manufacturing and operation, the state can ensure that EVs meet specific standards, contributing to a cleaner and more sustainable transportation ecosystem. This testing process is essential to maintain the integrity of the EV market and promote the widespread adoption of electric vehicles while adhering to the state's environmental regulations.

Georgia's EV Incentives: Unlocking the Green Car Revolution

You may want to see also

Frequently asked questions

The NYS Department of Motor Vehicles (DMV) has specific inspection guidelines for electric vehicles (EVs) to ensure their safety and environmental compliance. All EVs in New York State are required to undergo an annual safety inspection, similar to traditional gasoline or diesel vehicles. This inspection is mandatory for all EV owners and must be completed every 12 months to maintain vehicle registration.

The NYS inspection for EVs focuses on several unique aspects due to their distinct nature. Firstly, EVs are inspected for battery health and performance, ensuring the battery's voltage, amperage, and overall condition meet the required standards. Inspectors also check the charging system, including the charging port and cable, to guarantee safe and efficient charging. Additionally, the inspection may include an assessment of the vehicle's range and efficiency, especially for models with significant range variations.

Yes, the NYS inspection for EVs includes checks to ensure environmental compliance. Inspectors verify that the vehicle's emissions control system, such as the particulate filter and exhaust gas recirculation system, functions correctly. They also assess the vehicle's overall environmental impact, including its carbon footprint and energy efficiency. These checks help maintain the state's commitment to reducing greenhouse gas emissions and promoting sustainable transportation.