Electric vehicles (EVs) are known for their efficient and environmentally friendly power systems, which often involve advanced battery technology and electric motors. One aspect of these systems is the voltage used, which plays a crucial role in the performance and efficiency of the vehicle. In this context, it is important to explore whether electric vehicles have a low-voltage system and how this relates to their overall functionality. Understanding the voltage requirements and their impact on the vehicle's performance can provide valuable insights for both manufacturers and potential EV owners.

What You'll Learn

- Battery Voltage: Electric vehicles typically use high-voltage batteries, often 300-400 volts or more

- Power Electronics: Inverters and converters regulate voltage to power the electric motor and accessories

- Safety Systems: High voltage requires robust safety mechanisms to prevent electrical hazards

- Charging Systems: Chargers manage voltage during charging to protect the battery and charging infrastructure

- Performance Impact: Lower voltage can affect performance, range, and efficiency, requiring careful design

Battery Voltage: Electric vehicles typically use high-voltage batteries, often 300-400 volts or more

Electric vehicles (EVs) have revolutionized the automotive industry, offering an eco-friendly and efficient mode of transportation. One of the key components that set EVs apart is their battery system, which operates at significantly higher voltages compared to traditional internal combustion engines. The battery voltage in electric vehicles is a critical aspect that influences performance, efficiency, and overall driving experience.

When it comes to battery voltage, electric vehicles typically utilize high-voltage batteries, often ranging from 300 to 400 volts or even higher. This voltage level is much higher than the 12 volts commonly found in conventional vehicles. The higher voltage is essential for several reasons. Firstly, it enables efficient power delivery to the electric motor, ensuring quick acceleration and responsive performance. With a higher voltage, EVs can deliver the necessary torque and power to match or even surpass their internal combustion engine counterparts.

The high-voltage battery system in electric vehicles also contributes to improved energy efficiency. By utilizing a higher voltage, EVs can optimize energy conversion and minimize energy losses during the driving process. This results in better overall efficiency, allowing electric vehicles to travel longer distances on a single charge. Additionally, the high voltage facilitates the use of more compact and lightweight battery packs, making EVs more space-efficient and reducing overall vehicle weight.

Furthermore, the high voltage in electric vehicle batteries is crucial for safety. It enables the implementation of advanced safety features such as regenerative braking and sophisticated battery management systems. These systems help regulate voltage levels, monitor battery health, and ensure safe operation. The high voltage also allows for the integration of advanced driver-assistance systems (ADAS), enhancing the overall safety and driving experience.

In summary, electric vehicles' battery voltage is a critical design choice, offering numerous advantages. The high voltage of 300-400 volts or more provides efficient power delivery, improved energy efficiency, and enables the integration of advanced safety and driver-assistance features. As technology advances, we can expect further innovations in battery voltage and system design, making electric vehicles even more appealing and sustainable in the future.

Hydrogen vs. Electric: The Green Car Debate

You may want to see also

Power Electronics: Inverters and converters regulate voltage to power the electric motor and accessories

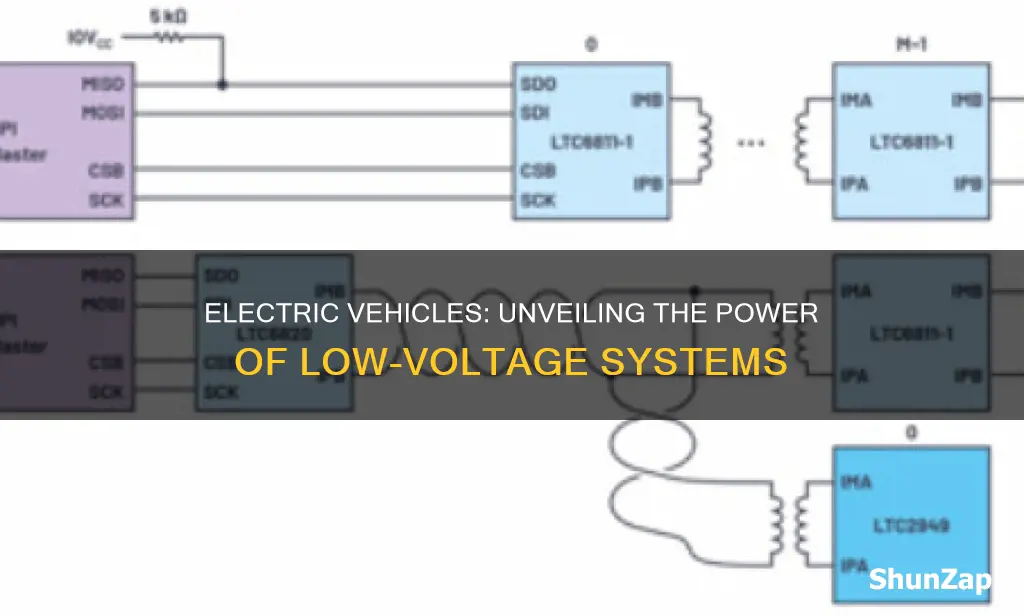

Power electronics play a crucial role in electric vehicles (EVs) by ensuring efficient and reliable voltage regulation for the electric motor and various accessories. Inverters and converters are essential components that enable the conversion and control of electrical energy, making them vital in the operation of EVs.

Inverters are devices that convert direct current (DC) into alternating current (AC), which is essential for powering the electric motor. The motor in an EV requires AC power to operate, and inverters provide this by taking the DC power from the battery and transforming it into the required AC waveform. This process involves generating a high-frequency AC signal, which is then used to drive the motor's rotor, thus producing the necessary torque for propulsion. The efficiency of the inverter is critical, as any losses in the conversion process can impact the overall performance and range of the vehicle.

Converters, on the other hand, are used to regulate and control the voltage and current in the system. They are particularly important in managing the power flow between the battery, motor, and other accessories. For instance, converters can step up or step down the voltage to ensure that the motor receives the appropriate power level. In some cases, converters are used to isolate the battery from the motor, providing a stable and controlled power supply. This isolation is crucial for safety and efficiency, especially during regenerative braking, where the motor acts as a generator, converting kinetic energy back into electrical energy.

The design and efficiency of these power electronics components are critical to the overall performance and reliability of electric vehicles. Modern EVs often utilize sophisticated inverter and converter systems that offer high power density, fast response times, and advanced control algorithms. These features enable efficient energy management, ensuring that the electric motor operates optimally while also powering other vehicle systems, such as lighting, heating, and infotainment, which are typically run by lower-voltage DC power.

In summary, power electronics, including inverters and converters, are integral to the functionality of electric vehicles. They facilitate the conversion and regulation of voltage, enabling the electric motor to operate efficiently and reliably. With ongoing advancements in power electronics technology, EVs can continue to improve in terms of performance, range, and overall driving experience.

Uncover the Mystery: Signs Your Car Has Electric Start

You may want to see also

Safety Systems: High voltage requires robust safety mechanisms to prevent electrical hazards

The high voltage systems in electric vehicles (EVs) present unique challenges and require specialized safety mechanisms to mitigate potential risks. Unlike traditional internal combustion engines, EVs operate at much higher voltage levels, typically ranging from 300 to 800 volts, which is significantly higher than the standard 12-volt systems found in conventional cars. This elevated voltage is essential for powering the vehicle's electric motor and other components, but it also demands a robust safety infrastructure to prevent electrical hazards.

One critical aspect of safety in high-voltage systems is the use of insulated components. Insulation plays a vital role in preventing electrical current from flowing where it shouldn't, ensuring that high-voltage parts remain isolated from low-voltage systems and the vehicle's occupants. This includes insulated wiring, connectors, and components like the high-voltage battery pack, which is often encased in a protective housing to minimize the risk of electrical shocks or short circuits.

Additionally, EVs employ sophisticated grounding systems to manage electrical charges. Grounding provides a safe path for electrical current to flow into the earth, preventing the buildup of static electricity and reducing the risk of electrical arcs or sparks. These grounding systems are carefully designed to handle the high currents and voltages present in the vehicle, ensuring that any potential electrical faults are safely directed away from the vehicle and its occupants.

Another essential safety feature is the implementation of protective circuits and fuses. These devices are strategically placed throughout the high-voltage system to limit the flow of current in case of an overload or short circuit. For instance, high-voltage fuses are designed to melt and interrupt the circuit when a specific current threshold is exceeded, preventing potential damage to the vehicle or harm to passengers.

Furthermore, the design of the high-voltage battery pack itself is crucial for safety. Battery packs are often equipped with advanced cooling systems and protective casings to maintain optimal operating temperatures and prevent overheating, which could lead to electrical malfunctions or fires. These safety measures are critical in ensuring that the high-voltage system operates reliably and safely, even under extreme conditions.

In summary, the high voltage in electric vehicles demands a comprehensive safety approach. By utilizing insulated components, effective grounding systems, protective circuits, and well-designed battery packs, EVs can ensure that the high-voltage system remains safe and reliable. These safety mechanisms are essential to address the unique challenges posed by high-voltage systems and to build consumer trust in the technology.

When Will VW's Electric Vehicles Be Available?

You may want to see also

Charging Systems: Chargers manage voltage during charging to protect the battery and charging infrastructure

The charging systems of electric vehicles (EVs) are designed with intricate mechanisms to ensure safe and efficient power transfer, especially when it comes to voltage management. When an EV is connected to a charger, the charging system's primary role is to regulate the voltage to match the battery's requirements while safeguarding both the battery and the charging infrastructure. This process is crucial as it prevents potential damage to the battery and the charging system itself.

During the charging process, chargers employ sophisticated voltage control systems. These systems monitor the voltage levels and adjust them accordingly to maintain a stable and optimal charging environment. The voltage management is essential because electric vehicle batteries are sensitive to overcharging, which can lead to reduced battery life and, in extreme cases, safety hazards. Chargers are programmed to detect the battery's voltage and initiate charging at the appropriate voltage level, typically starting from a lower voltage and gradually increasing it as the battery absorbs power.

One of the key advantages of this voltage management is the ability to protect the charging infrastructure. High voltage levels can stress the charging cables and connectors, potentially causing damage or even fire hazards. By regulating the voltage, chargers ensure that the power delivered to the vehicle remains within safe limits, reducing the risk of electrical faults and system failures. This is particularly important in public charging stations where multiple vehicles are charged simultaneously, and the charging infrastructure must handle varying voltage demands.

Moreover, the charging system's voltage control allows for a more efficient charging process. By optimizing the voltage, chargers can maximize the power transfer rate while minimizing energy losses. This efficiency is vital for reducing charging times and ensuring that EVs are ready for use more quickly. The system's intelligence in managing voltage also contributes to the overall longevity of the battery, as it prevents over-voltage conditions that could accelerate battery degradation.

In summary, the charging systems of electric vehicles are equipped with advanced voltage management capabilities. These systems play a critical role in safeguarding the battery's health and the integrity of the charging infrastructure. By carefully regulating voltage during the charging process, chargers ensure a safe, efficient, and prolonged battery life for electric vehicles. This technology is a cornerstone of the EV charging infrastructure, enabling the widespread adoption of electric mobility.

Unleash Savings: Tax Incentives for Your Electric Vehicle Purchase

You may want to see also

Performance Impact: Lower voltage can affect performance, range, and efficiency, requiring careful design

The concept of a lower voltage system in electric vehicles (EVs) is an intriguing one, but it presents several performance challenges that require careful engineering and design considerations. Lowering the voltage in an EV's electrical system can have a significant impact on its overall performance, range, and efficiency, making it a delicate balance to strike.

One of the primary concerns is the effect on power output. Electric motors rely on a consistent and sufficient voltage supply to deliver the required torque and power. When voltage is reduced, the motor's performance can be compromised, resulting in decreased acceleration and overall driving experience. This is particularly critical for EVs, as they need to provide instant torque for smooth and responsive driving, especially during acceleration. Lower voltage may lead to reduced power delivery, affecting the vehicle's ability to accelerate quickly and efficiently.

The range of an EV is another critical aspect influenced by voltage. Lower voltage can impact the efficiency of energy conversion and transmission, potentially reducing the vehicle's range. This is especially true for high-power applications where efficient energy management is essential. Designers must ensure that the voltage system is optimized to minimize energy losses and maximize the range, especially for long-distance travel.

Efficiency is a key differentiator for electric vehicles, and a lower voltage system can introduce inefficiencies. The electrical components, such as inverters and converters, may not operate optimally at reduced voltage, leading to increased energy consumption and reduced overall efficiency. This inefficiency can result in higher energy costs for the vehicle owner and potentially shorter battery life.

Careful design and engineering are essential to mitigate these performance impacts. Designers must consider the specific requirements of the EV, including its intended use, driving conditions, and target range. Advanced voltage regulation techniques, such as adaptive voltage control and efficient power electronics, can help manage the voltage levels and ensure optimal performance. Additionally, optimizing the battery pack's voltage and current ratings can contribute to better overall efficiency and performance.

In summary, while a lower voltage system in electric vehicles might seem like a potential cost-saving measure, it can significantly impact performance, range, and efficiency. Achieving the right balance requires a deep understanding of EV technology and careful design choices to ensure that the vehicle meets the desired performance standards while also being energy-efficient and environmentally friendly.

Unraveling the Mystery: The Brain Behind Vehicle Electrical Systems

You may want to see also

Frequently asked questions

Electric vehicles (EVs) typically use a low-voltage system, usually around 12 volts, for various auxiliary functions. This system powers accessories like lights, wipers, and the radio, ensuring these components operate efficiently without draining the high-voltage battery.

The low-voltage system is isolated from the high-voltage battery to prevent power drain. It is powered by a dedicated 12V battery or a converter that steps down the high-voltage output. This setup allows the vehicle to manage energy efficiently, ensuring the main battery is used primarily for propulsion.

While the low-voltage system is designed to be minimal impact, it can influence the vehicle's performance. Accessories powered by this system may draw power when not in use, potentially reducing the range. However, modern EVs are equipped with smart management systems that optimize power distribution, ensuring the low-voltage system's impact is minimized.