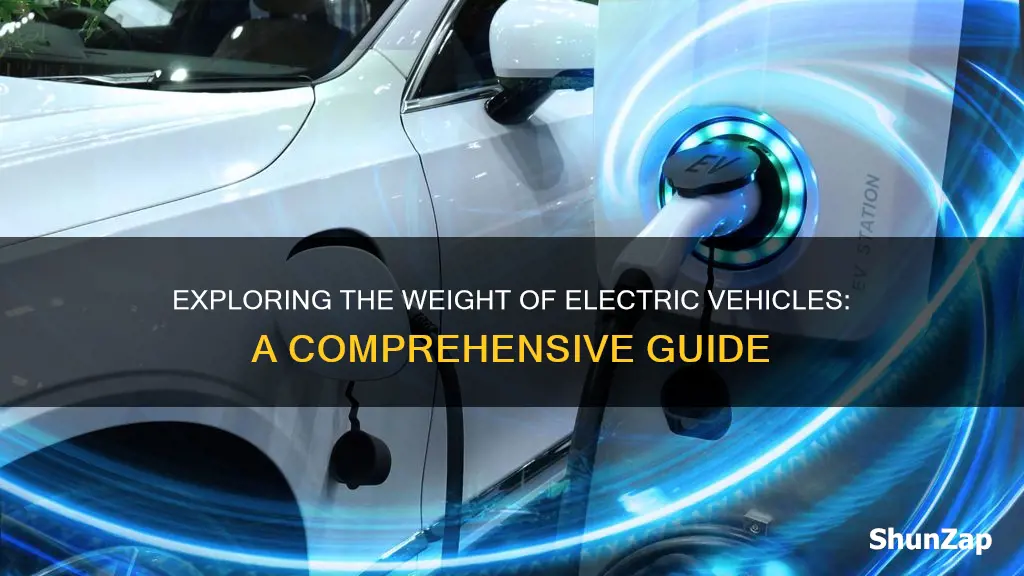

Electric vehicles (EVs) have gained significant popularity in recent years, offering a sustainable and eco-friendly alternative to traditional gasoline-powered cars. One of the key considerations for potential EV buyers is the weight of these vehicles, as it can impact performance, handling, and overall driving experience. The weight of electric cars varies depending on factors such as battery size, motor power, and design choices. While some EVs are designed to be lightweight, others prioritize battery capacity and range, resulting in heavier vehicles. Understanding the weight distribution and its implications is essential for consumers to make informed decisions when choosing an electric vehicle that aligns with their specific needs and preferences.

What You'll Learn

Weight Comparison: EVs vs. Gasoline Cars

The weight of electric vehicles (EVs) is a crucial aspect to consider when comparing them to their gasoline counterparts. One of the most significant differences lies in the power source and the associated components. EVs are equipped with large batteries, which are heavier than the traditional fuel tanks found in gasoline cars. These batteries store the energy required to power the vehicle, and their weight can vary depending on the vehicle's range and battery capacity. For instance, a compact EV with a shorter range might have a smaller battery pack, resulting in a lighter overall weight compared to a full-size EV with a longer driving range.

On average, electric cars tend to be heavier than their gasoline-powered equivalents due to the additional weight of the battery pack. The weight distribution also plays a role in handling and performance. EVs often have a lower center of gravity due to the placement of the battery pack, which can improve stability and cornering abilities. However, the increased weight can also impact acceleration and overall driving dynamics.

Gasoline cars, on the other hand, have a more conventional design with an engine, fuel tank, and associated components. The weight of these components can vary based on the engine size and the overall vehicle architecture. Smaller engines and more efficient designs can result in lighter weights, while larger engines and more powerful vehicles will naturally be heavier.

When comparing specific models, it's essential to consider the battery chemistry and design. For example, lithium-ion batteries are commonly used in EVs and offer high energy density, contributing to the overall weight. However, other battery technologies, like nickel-metal hydride, might be used in certain applications, affecting the weight and performance characteristics.

In summary, electric vehicles generally weigh more than their gasoline counterparts due to the heavy battery packs. This additional weight influences the driving experience and performance but also contributes to the overall efficiency of EVs. Understanding the weight distribution and the factors affecting it is crucial for consumers and manufacturers alike when designing and comparing these vehicles.

Green Revolution: Electric Vehicles' Impact on Earth's Future

You may want to see also

Battery Weight: Impact on Vehicle Performance

The weight of the battery pack is a critical factor in the performance and efficiency of electric vehicles (EVs). As the primary energy storage system, the battery's weight directly influences the overall weight distribution, handling, and driving experience of the vehicle. Understanding the impact of battery weight is essential for both manufacturers and potential EV buyers.

Heavier batteries can significantly affect an EV's performance. Firstly, the additional weight increases the vehicle's overall mass, which in turn affects its acceleration and top speed. Heavier EVs often experience a slower 0-60 mph time, as the motor has to overcome more inertia. This can be a concern for enthusiasts who value quick acceleration. Moreover, the weight distribution becomes crucial, especially in high-performance EVs, where precise handling and cornering are desired.

Battery weight also plays a role in energy efficiency. When an EV carries a heavier battery, it requires more energy to accelerate and maintain speed, leading to increased energy consumption. This can result in reduced range, as the vehicle's efficiency is directly impacted by its weight. For instance, a study comparing lightweight and heavy-duty EVs found that the latter experienced a 5-10% decrease in range due to the additional battery weight.

Furthermore, the weight of the battery pack influences the vehicle's center of gravity. A higher center of gravity can make the EV more prone to rolling over, especially during sharp turns or sudden maneuvers. This is a critical safety consideration, as it affects the vehicle's stability and crashworthiness. Manufacturers often employ various design strategies to optimize weight distribution and maintain a low center of gravity, ensuring a safer driving experience.

In summary, the weight of the battery pack is a critical aspect of EV design and performance. It influences acceleration, handling, energy efficiency, and safety. As technology advances, manufacturers strive to develop lightweight battery solutions without compromising on energy storage capacity, ensuring that electric vehicles offer a balance between performance and efficiency. Understanding these factors can help consumers make informed decisions when choosing an EV that aligns with their specific needs and preferences.

Electric Vehicles: Special Auto Body Needs Explored

You may want to see also

Lightweight Materials: Innovations in EV Construction

The automotive industry has been undergoing a significant transformation with the rise of electric vehicles (EVs), and one of the key areas of innovation is in the construction of these vehicles, particularly focusing on lightweight materials. The weight of an EV is a critical factor in its performance, efficiency, and overall driving experience. Heavier vehicles tend to have higher energy consumption, reduced range, and slower acceleration, which are common concerns for EV owners. Therefore, the development of lightweight materials has become a crucial aspect of EV manufacturing.

Lightweight materials offer numerous advantages in EV construction. Firstly, they contribute to a significant reduction in vehicle weight without compromising structural integrity. This is achieved through the use of advanced composites, such as carbon fiber-reinforced polymers (CFRP), which provide exceptional strength-to-weight ratios. By incorporating these materials in key components like body panels, chassis, and even battery enclosures, manufacturers can achieve a substantial weight reduction. For instance, a study comparing traditional steel-bodied vehicles with those utilizing lightweight composites revealed that the latter could achieve a weight reduction of up to 30% while maintaining the necessary safety and durability standards.

Another innovation in lightweight EV construction is the utilization of advanced alloys and metals. These materials offer improved strength and corrosion resistance compared to conventional steel. For example, high-strength steel alloys, such as those containing aluminum or copper, can be used in the vehicle's frame and body, providing structural rigidity while keeping the overall weight low. Additionally, the development of lightweight aluminum alloys has been instrumental in reducing vehicle weight, especially in the battery and motor components, where weight savings can directly translate to increased range and improved performance.

The benefits of lightweight materials extend beyond weight reduction. These materials often offer enhanced thermal and acoustic properties, contributing to improved energy efficiency and a quieter driving experience. For instance, lightweight composites can be designed to have better thermal conductivity, aiding in efficient heat management within the vehicle. Furthermore, the use of advanced materials can lead to reduced manufacturing costs in the long term, as these materials often require less energy and resources during production, making the manufacturing process more sustainable.

In conclusion, the integration of lightweight materials in EV construction is a pivotal innovation that addresses several key challenges in the automotive industry. By reducing vehicle weight, manufacturers can improve performance, increase range, and enhance the overall driving experience. The use of advanced composites, alloys, and metals not only contributes to weight reduction but also offers improved structural integrity, thermal management, and acoustic properties. As the demand for efficient and sustainable transportation continues to grow, the adoption of lightweight materials in EV construction will likely become even more widespread, shaping the future of the automotive industry.

Electric Scooters: Unveiling the Speed Limits and Their Classification

You may want to see also

Efficiency: How Weight Affects Range and Speed

The weight of an electric vehicle (EV) is a critical factor that significantly influences its efficiency, particularly in terms of range and speed. Heavier EVs generally face challenges in achieving optimal performance, which can impact the overall driving experience and the vehicle's environmental footprint. Here's an in-depth look at the relationship between weight and efficiency in electric vehicles:

Impact on Range:

The range of an EV is a major concern for potential buyers, and weight plays a pivotal role in determining how far a vehicle can travel on a single charge. Heavier EVs require more energy to accelerate and maintain speed, which directly translates to increased power consumption. As a result, heavier vehicles tend to have shorter ranges compared to their lighter counterparts. This is especially noticeable in compact EVs, where a slight increase in weight can lead to a noticeable reduction in the range per charge. For instance, a study comparing the range of various compact EVs revealed that a 100-pound weight increase could reduce the range by up to 5-10 miles per charge.

Energy Efficiency and Weight Distribution:

The distribution of weight within an EV also matters. Modern EVs often feature advanced battery placement to optimize weight distribution, ensuring a lower center of gravity. This design choice not only enhances stability but also improves energy efficiency. A well-balanced weight distribution allows the vehicle to maintain a more consistent speed and power output, resulting in better energy efficiency. In contrast, uneven weight distribution can lead to increased rolling resistance, especially during cornering, which further reduces the vehicle's range.

Speed and Acceleration:

Weight directly affects an EV's acceleration capabilities. Heavier vehicles require more force to overcome inertia and reach higher speeds. As a result, they tend to have slower acceleration times compared to lighter EVs. This is particularly noticeable when driving uphill or during rapid maneuvers. The relationship between weight and speed is linear; heavier EVs will generally take longer to reach the same speed as lighter vehicles. However, it's worth noting that modern EV designs, including advanced aerodynamics and lightweight materials, have helped mitigate some of these speed-related challenges.

Optimizing Efficiency:

To maximize efficiency, EV manufacturers focus on using lightweight materials without compromising structural integrity. Carbon fiber composites, high-strength steel, and advanced alloys are becoming increasingly common in EV construction. These materials offer excellent strength-to-weight ratios, allowing for reduced vehicle weight while maintaining safety and durability. Additionally, regenerative braking systems, which convert kinetic energy back into usable electricity, further enhance efficiency by reducing the energy required for braking.

In summary, the weight of an electric vehicle is a critical consideration for efficiency, especially in terms of range and speed. Heavier EVs face challenges in achieving optimal performance, and manufacturers are continually working to optimize designs, materials, and technologies to address these issues. Understanding the impact of weight on efficiency is essential for EV owners and enthusiasts, as it highlights the importance of lightweight construction in the pursuit of sustainable and high-performing electric mobility.

The Future of Driving: Embracing All-Electric Vehicles

You may want to see also

Recycling: Sustainable Practices for EV Batteries

The growing popularity of electric vehicles (EVs) has led to an increasing focus on sustainable practices, particularly in the recycling of EV batteries. As the demand for EVs rises, so does the need to address the environmental impact of their batteries, which can be heavy and contain valuable and potentially hazardous materials. Recycling EV batteries is crucial to ensure a circular economy, reduce waste, and minimize the extraction of raw materials.

EV batteries, often lithium-ion, are composed of various components, including lithium, cobalt, nickel, and manganese. These materials are valuable and can be recovered through proper recycling processes. The weight of EV batteries can vary depending on the model and size, but they typically range from several hundred to over a thousand pounds. For instance, a common 60 kWh battery pack used in many EVs can weigh around 400-500 pounds. This weight is significant and must be managed carefully during the recycling process to ensure safety and efficiency.

Recycling EV batteries involves several stages to extract valuable materials and minimize environmental impact. Firstly, the batteries are carefully disassembled to separate the various components. This process requires specialized equipment and skilled workers to handle the heavy batteries and ensure a safe environment. Once disassembled, the different materials can be processed and recycled. Lithium, for example, can be recovered through a process called direct lithium extraction, where it is separated from the battery's electrolyte. Cobalt, nickel, and manganese can also be extracted and reused in new batteries or other industrial applications.

The recycling process also focuses on minimizing the environmental impact of battery disposal. Many older EV batteries contain heavy metals and chemicals that, if not handled properly, can leach into the environment. Recycling facilities employ advanced techniques to prevent such contamination. This includes specialized chemical treatments and processes to neutralize or stabilize hazardous materials, ensuring that the recycling process itself does not contribute to environmental degradation.

In addition to recycling, sustainable practices also involve the development of second-life applications for EV batteries. After their initial use, batteries may still retain a significant amount of capacity and can be repurposed for less demanding applications. This approach extends the lifespan of the batteries, reducing the need for new material extraction and minimizing waste. Second-life batteries can be used in energy storage systems, providing a stable power source for homes, businesses, or even entire communities.

In summary, recycling EV batteries is a critical aspect of sustainable practices in the EV industry. It allows for the recovery of valuable materials, reduces the environmental impact of battery disposal, and promotes a circular economy. As the EV market continues to grow, implementing efficient and safe recycling methods will be essential to ensure a greener and more sustainable future for transportation.

The Ultimate Guide to Choosing Your Perfect Electric Car

You may want to see also

Frequently asked questions

Electric vehicles generally have a higher weight due to their battery packs and electric motor components. On average, EVs weigh between 3,000 to 5,000 pounds (1,360 to 2,270 kg), which is about 1,000 to 1,500 pounds (450 to 680 kg) heavier than a comparable gasoline vehicle. This additional weight is often attributed to the advanced battery technology used in EVs.

Yes, the weight can vary significantly across different EV models. For instance, compact EVs like the Tesla Model 3 might weigh around 3,500 pounds (1,590 kg), while larger SUVs like the Lucid Air can tip the scales at over 4,500 pounds (2,040 kg). The battery pack's capacity and placement also play a role; some EVs have larger batteries in the floor, which can affect the vehicle's center of gravity and overall weight distribution.

The additional weight in EVs can provide several benefits. Firstly, it contributes to better handling and stability, especially in high-speed driving. The weight distribution can also enhance the vehicle's performance and reduce body roll during cornering. Moreover, the battery pack acts as a counterweight, improving the overall balance of the car.

The weight of an EV can influence its acceleration, top speed, and overall efficiency. Heavier EVs might have slightly longer acceleration times due to the increased mass, but they often provide better range and efficiency. The weight can also affect the vehicle's power-to-weight ratio, which is a critical factor in determining its performance characteristics.

Manufacturers are constantly exploring ways to optimize the weight of EVs. This includes using lightweight materials like carbon fiber composites, advanced alloys, and high-strength steel. Some EVs also employ innovative battery designs, such as solid-state batteries, which could potentially reduce weight while increasing energy density. These efforts aim to improve the overall efficiency and driving experience of electric vehicles.