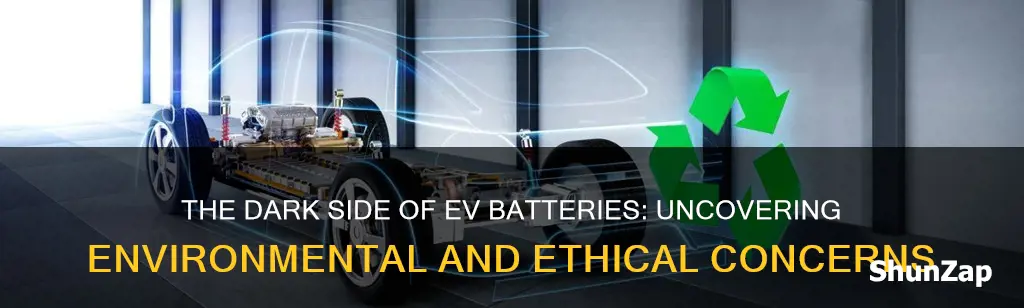

Electric vehicle batteries have revolutionized the automotive industry, offering a sustainable alternative to traditional combustion engines. However, their widespread adoption is not without challenges. The environmental impact of battery production and disposal, coupled with the finite nature of battery resources, raises concerns about the long-term sustainability of electric vehicles. Additionally, the high cost of battery technology and the need for extensive charging infrastructure present significant barriers to widespread adoption. This paragraph introduces the topic of the environmental, economic, and logistical challenges associated with electric vehicle batteries, highlighting the need for further research and development to address these issues.

| Characteristics | Values |

|---|---|

| Environmental Impact | Electric vehicle batteries have a significant environmental impact during production and end-of-life disposal. The manufacturing process can release pollutants and greenhouse gases, and the extraction of raw materials can lead to habitat destruction and water pollution. |

| Resource Intensity | Battery production requires large amounts of raw materials, including lithium, cobalt, nickel, and rare earth elements. The extraction and processing of these materials can have environmental and social consequences, especially in regions with limited regulations. |

| Recycling Challenges | Recycling lithium-ion batteries is complex and costly. Current recycling methods can recover only a fraction of the valuable materials, and the process may generate hazardous waste. Improving recycling technologies is crucial to reducing the environmental impact. |

| Fire and Safety Risks | Lithium-ion batteries can pose fire and safety hazards due to their volatile nature. While rare, battery fires can occur, and the risk increases with age and damage. Proper design, manufacturing, and usage guidelines are essential to mitigate these risks. |

| Limited Lifespan | Battery performance degrades over time, and their lifespan is typically around 8-10 years. This can lead to increased waste generation as batteries reach the end of their useful life. Research is ongoing to improve battery longevity and develop more sustainable disposal methods. |

| Weight and Space Requirements | Electric vehicles (EVs) require large batteries to achieve adequate range, which adds significant weight and takes up space. This can impact vehicle performance, especially in compact or sports car designs. |

| Cost | High initial costs of EV batteries are a barrier to widespread adoption. While prices have been decreasing, the cost of batteries remains a significant factor in the overall price of EVs. |

| Supply Chain Vulnerabilities | The supply chain for battery materials is complex and susceptible to geopolitical risks. Disruptions in mining, processing, and transportation can affect the availability and cost of batteries. |

| Second-Life Applications | Used EV batteries can be repurposed for energy storage systems, providing a second life and potential revenue stream. However, finding suitable applications and managing the used batteries is a challenge. |

| Research and Development | Ongoing research aims to address battery-related issues, including energy density, charging speed, safety, and sustainability. Advances in solid-state batteries and recycling technologies are promising areas of development. |

What You'll Learn

- Environmental Impact: Manufacturing EV batteries has high resource extraction and energy costs, impacting ecosystems

- Recycling Challenges: Current recycling methods are energy-intensive and may release pollutants, requiring improvement

- Raw Material Sourcing: Ethical and sustainable sourcing of lithium, cobalt, and nickel is a significant concern

- Battery Waste: Proper disposal and end-of-life management of used batteries are crucial to minimize environmental harm

- Fire Risks: Lithium-ion batteries can catch fire, posing safety risks and requiring advanced safety mechanisms

Environmental Impact: Manufacturing EV batteries has high resource extraction and energy costs, impacting ecosystems

The environmental impact of electric vehicle (EV) batteries is a critical aspect often overlooked in the broader discussion of sustainable transportation. The manufacturing process of these batteries is energy-intensive and involves significant resource extraction, which can have detrimental effects on ecosystems and the environment.

One of the primary concerns is the extraction of raw materials. EV batteries, particularly lithium-ion batteries, require a substantial amount of lithium, cobalt, nickel, and other rare earth elements. These materials are often sourced through mining, a process that can lead to habitat destruction, soil erosion, and water pollution. For instance, lithium mining can result in the degradation of local ecosystems, affecting wildlife and plant life. The energy-intensive nature of mining operations further exacerbates the environmental impact, as it often relies on fossil fuels, contributing to greenhouse gas emissions.

The energy costs associated with battery manufacturing are another significant factor. The production of EV batteries involves complex processes, including refining, chemical synthesis, and assembly, all of which require substantial energy. The majority of this energy is derived from non-renewable sources, such as coal and natural gas, which release carbon dioxide and other pollutants into the atmosphere. As a result, the manufacturing process contributes to air pollution and increases the carbon footprint of the entire EV industry.

Furthermore, the environmental impact extends beyond the initial manufacturing phase. The disposal and recycling of EV batteries also pose challenges. When batteries reach the end of their life, they must be carefully managed to prevent hazardous waste. Improper disposal can lead to soil and water contamination, as these batteries contain toxic chemicals. Recycling processes, while essential for sustainability, are energy-intensive and may also have ecological consequences if not executed properly.

To address these environmental concerns, it is crucial to explore and implement more sustainable practices. This includes developing more efficient extraction methods to reduce the ecological footprint of mining, transitioning to renewable energy sources for manufacturing, and establishing comprehensive recycling infrastructure. By doing so, the EV industry can work towards mitigating the high resource extraction and energy costs associated with battery production, thereby minimizing its impact on ecosystems and the environment.

Saudi Arabia's Electric Future: A Green Revolution

You may want to see also

Recycling Challenges: Current recycling methods are energy-intensive and may release pollutants, requiring improvement

The recycling of electric vehicle (EV) batteries presents a unique set of challenges that require careful consideration and innovative solutions. While the widespread adoption of EVs is crucial for reducing greenhouse gas emissions and combating climate change, the environmental impact of their batteries, particularly during the recycling process, is a growing concern. Current recycling methods often involve energy-intensive processes that can release pollutants, highlighting the need for improvement in this critical area.

One of the primary issues with EV battery recycling is the energy-intensive nature of the process. Many recycling techniques, such as pyrometallurgy, which involves high-temperature melting, are not only energy-intensive but also generate significant amounts of greenhouse gases. This is particularly problematic given the goal of reducing carbon emissions. For instance, the process of recovering metals like lithium, cobalt, and nickel from spent batteries can require substantial energy input, often derived from fossil fuels, leading to a net increase in carbon emissions.

Furthermore, the recycling of EV batteries can release various pollutants, including heavy metals and volatile organic compounds (VOCs). These pollutants can have detrimental effects on both the environment and human health. For example, the release of cobalt, lead, and other toxic elements during the recycling process can contaminate soil and water sources, posing risks to ecosystems and nearby communities. Additionally, the combustion and chemical processes involved in recycling can emit air pollutants, contributing to air quality issues.

To address these challenges, researchers and engineers are exploring more sustainable and environmentally friendly recycling methods. One promising approach is hydrometallurgy, which uses chemical processes to extract metals from the battery materials. This method is less energy-intensive and can potentially reduce the release of pollutants. Another strategy is to improve the design of EV batteries to make them more recyclable. This includes using materials that are easier to separate and recycle, as well as designing batteries with end-of-life considerations in mind.

In conclusion, the recycling of electric vehicle batteries is a critical aspect of the EV ecosystem that requires attention and improvement. The current methods' energy intensity and potential for pollutant release highlight the need for more sustainable and efficient recycling processes. By adopting innovative techniques and rethinking battery design, it is possible to overcome these challenges and ensure that the benefits of EVs contribute to a greener and more sustainable future. This includes minimizing environmental impact and maximizing the potential for a circular economy in the EV battery recycling sector.

Powering Electric Vehicles: Essential Services for a Sustainable Future

You may want to see also

Raw Material Sourcing: Ethical and sustainable sourcing of lithium, cobalt, and nickel is a significant concern

The ethical and sustainable sourcing of raw materials for electric vehicle (EV) batteries is a critical issue that cannot be overlooked. The increasing demand for EVs has led to a surge in the need for lithium, cobalt, and nickel, which are essential components of their batteries. However, the extraction and supply chains of these materials are often associated with significant environmental and social challenges.

Lithium, for instance, is primarily sourced through the extraction of lithium-rich brine from underground salt flats. This process can have detrimental effects on local ecosystems and water resources. The evaporation ponds used for lithium extraction can lead to soil degradation and water pollution, impacting nearby communities and wildlife. Furthermore, the energy-intensive nature of lithium production and the potential for water scarcity in certain regions raise concerns about the long-term sustainability of this resource.

Cobalt, another critical component, is predominantly mined in the Democratic Republic of Congo (DRC). The mining industry in the DRC has been plagued by human rights abuses, including child labor and forced labor. The working conditions in these mines are often hazardous, with miners facing exposure to toxic chemicals and inadequate safety measures. Additionally, the conflict-ridden regions where these mines are located have contributed to environmental degradation and social instability.

Nickel, while not as directly associated with human rights issues as cobalt, also presents environmental and ethical challenges. The extraction of nickel often involves open-pit mining, which can result in habitat destruction and soil erosion. Furthermore, the processing of nickel can release toxic substances into the environment, posing risks to both human health and local ecosystems.

To address these concerns, EV manufacturers and battery producers are increasingly focusing on implementing sustainable and ethical sourcing practices. This includes investing in recycling technologies to reduce the reliance on primary mineral extraction and promoting responsible mining practices. Some companies are also exploring alternative materials and production methods to minimize the environmental impact of battery production.

In conclusion, the raw material sourcing for EV batteries is a complex issue that requires a multifaceted approach. By prioritizing ethical and sustainable practices, the industry can work towards mitigating the environmental and social consequences of extracting lithium, cobalt, and nickel. Consumers and policymakers also play a crucial role in driving demand for responsibly sourced materials and holding companies accountable for their supply chain practices.

Electric Vehicle Mileage: Understanding the Annual Standard

You may want to see also

Battery Waste: Proper disposal and end-of-life management of used batteries are crucial to minimize environmental harm

The increasing adoption of electric vehicles (EVs) has brought about a revolution in the automotive industry, offering a more sustainable and environmentally friendly mode of transportation. However, the environmental impact of EV batteries, particularly their end-of-life (EOL) management, is a growing concern that requires immediate attention. Proper disposal and recycling of used batteries are essential to mitigate the potential harm to the environment and ensure a sustainable future for the EV market.

EV batteries, primarily lithium-ion, contain valuable and hazardous materials. These batteries are designed to be long-lasting, but their performance degrades over time, leading to reduced capacity and eventual replacement. When these batteries reach their EOL, they must be handled with care to prevent environmental contamination. The process of recycling and disposing of batteries involves complex procedures to extract valuable metals like cobalt, nickel, and lithium while safely managing toxic substances such as lead, cadmium, and lithium-ion itself.

Improper disposal of EV batteries can have severe consequences. If not recycled or disposed of correctly, these batteries can release toxic chemicals and heavy metals into the environment. For instance, lithium-ion batteries can catch fire or explode if damaged or exposed to high temperatures, posing a significant risk to both human health and the ecosystem. Furthermore, the chemicals and metals within the batteries can leach into the soil and water, leading to soil and water pollution, which can have long-lasting effects on local ecosystems and human health.

To address this issue, manufacturers and policymakers must collaborate to establish comprehensive recycling programs and infrastructure. These programs should aim to recover valuable materials from used batteries, reducing the demand for raw materials mining and minimizing the environmental impact of extraction processes. Additionally, educating consumers about the importance of proper battery disposal and providing accessible recycling options can significantly contribute to a more sustainable approach to EV ownership.

In summary, the proper disposal and end-of-life management of EV batteries are critical aspects of the EV industry's sustainability. By implementing effective recycling practices and raising awareness, we can ensure that the benefits of electric vehicles do not come at the cost of environmental degradation. It is through responsible handling and recycling that we can minimize the potential harm of EV batteries and contribute to a greener and more sustainable future.

Chrysler's Electric Evolution: A New Era of Sustainable Mobility

You may want to see also

Fire Risks: Lithium-ion batteries can catch fire, posing safety risks and requiring advanced safety mechanisms

The lithium-ion batteries used in electric vehicles (EVs) have been a subject of concern due to their potential fire risks, which can pose significant safety challenges. These batteries, while efficient and high-capacity, contain volatile and flammable components, making them susceptible to thermal runaway and fire incidents. The issue is particularly critical as it can lead to severe consequences, including vehicle damage, personal injuries, and even loss of life.

One of the primary causes of fire in lithium-ion batteries is the potential for short circuits. These batteries consist of multiple cells, and if one cell experiences a malfunction or damage, it can lead to a chain reaction, causing adjacent cells to short-circuit. Short circuits generate excessive heat, which can rapidly escalate into a full-blown fire. This is especially problematic in the confined spaces of an EV, where the battery pack is often located close to other components and occupants.

To mitigate these fire risks, manufacturers have implemented various safety mechanisms. One common approach is the use of thermal management systems. These systems actively monitor and control the temperature of the battery pack, ensuring it remains within safe limits. They can detect early signs of overheating and activate cooling mechanisms to prevent thermal runaway. Additionally, advanced battery management systems (BMS) play a crucial role in fire prevention. BMS continuously monitors the battery's performance, voltage, and temperature, allowing for real-time adjustments to optimize safety.

Another critical aspect of fire prevention is the design and construction of the battery pack itself. Modern EV designs often incorporate fire-resistant materials and structures to contain potential fires. This includes the use of protective casings, fire-resistant barriers, and even fire-extinguishing systems that can be triggered automatically. These safety measures aim to minimize the impact of a fire event and protect both the vehicle and its occupants.

Despite these advancements, the fire risks associated with lithium-ion batteries remain a complex issue. Ongoing research and development efforts are focused on further improving battery safety, including the development of more stable electrolytes, advanced cooling technologies, and enhanced BMS algorithms. As the adoption of electric vehicles continues to grow, addressing these fire risks is essential to ensure the widespread acceptance and safety of this innovative transportation technology.

Unveiling the Mystery: Ice in Electric Vehicles

You may want to see also

Frequently asked questions

While electric vehicle batteries can pose certain risks, they are generally designed with safety measures to minimize hazards. Lithium-ion batteries, commonly used in EVs, can catch fire or explode under extreme conditions, but modern vehicles have safety mechanisms to prevent such incidents. These include thermal management systems, pressure relief valves, and advanced battery management software.

The lifespan of an electric vehicle battery depends on various factors, including the type of battery, usage patterns, climate, and maintenance. On average, EV batteries can last between 8 to 15 years. With proper care and regular maintenance, such as keeping the battery charged and avoiding extreme temperatures, their longevity can be extended.

Running out of power in an electric vehicle can be a concern, but modern EVs have range anxiety solutions. Most electric cars have a range of over 200 miles on a single charge, and rapid charging stations are becoming increasingly common. In case of a dead battery, the vehicle will typically display a warning, and the driver can use the remaining power to reach a charging station or a safe location.

Yes, electric vehicle batteries are recyclable, and recycling processes are being developed to handle the increasing number of batteries that will become obsolete. Recycling helps recover valuable materials like lithium, cobalt, and nickel, reducing the need for mining and minimizing environmental impact. Many automotive manufacturers and startups are investing in battery recycling technologies.

Yes, it is normal for electric vehicle batteries to experience capacity degradation over time. This means their ability to store and deliver energy will gradually decrease. Factors like temperature, charging habits, and age contribute to this degradation. However, advancements in battery technology and management systems aim to optimize performance and minimize capacity loss.