Scrapping an electric vehicle (EV) can be a complex process, especially when compared to traditional internal combustion engine (ICE) vehicles. The process involves more than just removing the battery pack and other components; it requires careful consideration of environmental and safety regulations, as well as the proper disposal of hazardous materials. This guide will provide an overview of the steps involved in scrapping an EV, including the importance of recycling and the potential challenges you may face. It will also offer tips on how to navigate the legal and environmental aspects of the process, ensuring that the EV is disposed of responsibly and in compliance with local regulations.

What You'll Learn

- Battery Removal: Carefully extract the battery pack, ensuring proper handling and safety

- Motor Disassembly: Follow manufacturer guidelines to dismantle the electric motor for inspection

- Wiring Harness Extraction: Identify and carefully separate the complex wiring system

- Frame Structure: Understand the vehicle's frame to access and remove key components

- Recycling Processes: Learn about end-of-life recycling methods for EV materials

Battery Removal: Carefully extract the battery pack, ensuring proper handling and safety

Battery removal is a critical step in the process of scrapping an electric vehicle, and it requires careful planning and execution to ensure safety and proper handling. Here's a detailed guide on how to approach this task:

Preparation and Safety Measures: Before attempting to remove the battery pack, it is crucial to prioritize safety. Electric vehicles are equipped with advanced safety features, and the battery pack is a high-voltage component. Start by disconnecting the vehicle's power supply and ensuring that the battery is in a discharged state. Use appropriate personal protective equipment (PPE), including gloves and eye protection, to safeguard against any potential hazards. It is recommended to work in a well-ventilated area or outdoors to minimize the risk of inhaling any harmful fumes.

Locate the Battery Pack: Identify the battery pack's location, which is typically found under the floor or in the trunk of the vehicle. The pack is usually secured with various mounting brackets and fasteners. Carefully inspect the vehicle's manual or consult online resources specific to your vehicle model to understand the exact layout and any unique features of the battery compartment.

Release Safety Mechanisms: Electric vehicles have safety mechanisms to prevent accidental battery removal. Locate and release these mechanisms, which may include latches, locks, or release buttons. These features are designed to ensure that the battery pack cannot be removed without proper authorization. Follow the manufacturer's guidelines to safely engage these release mechanisms.

Careful Extraction: With the safety measures in place, begin the process of removing the battery pack. Start by unscrewing or unclipping any fasteners that secure the pack to the vehicle's frame. Take your time and be gentle to avoid damaging the connections or the vehicle's interior. Carefully lift the battery pack out of its compartment, ensuring that it is balanced and secure. If the pack is heavy, consider using a lifting aid or seeking assistance to prevent strain or injury.

Transport and Storage: Once the battery pack is removed, handle it with care. Place it on a flat surface or secure it in a suitable container to prevent damage during transport. Ensure that the pack is stored in a cool, dry place, away from direct sunlight and extreme temperatures. Proper storage is essential to maintain the battery's health and prevent any potential hazards.

Remember, battery removal should only be attempted by trained professionals or individuals with the necessary expertise. The process can be complex, and improper handling may lead to safety risks. Always follow manufacturer guidelines and consider seeking professional assistance to ensure a safe and efficient battery removal process.

Green Revolution: A Guide to Fleet Conversion to Electric Vehicles

You may want to see also

Motor Disassembly: Follow manufacturer guidelines to dismantle the electric motor for inspection

When it comes to dismantling an electric motor for inspection, it's crucial to follow the manufacturer's guidelines to ensure a safe and efficient process. These guidelines are designed to provide instructions specific to the motor's design and components, ensuring that the disassembly is carried out correctly and without causing any damage. Here's a step-by-step guide on how to approach this task:

Preparation: Before beginning the disassembly, ensure you have the necessary tools and equipment. This may include specialized tools for removing bolts and fasteners, such as torque wrenches and impact drivers. Also, have a clear workspace with good lighting to facilitate the process. It is essential to wear appropriate personal protective equipment (PPE) to protect yourself from any potential hazards during the disassembly.

Initial Steps: Start by locating the access points for the motor. These could be panels, covers, or specific release mechanisms designed to allow easy access to the motor. Carefully remove these panels or covers, ensuring you keep track of any screws or fasteners used to secure them. Follow the manufacturer's instructions to identify the correct order and method of removal. This step is crucial to avoid any accidental damage to the motor or its components.

Motor Dismantling: Once you have access to the motor, begin the disassembly process. This may involve removing the stator, rotor, or any other internal components. The manufacturer's guidelines will provide detailed instructions on how to carefully separate these parts. Take your time and be gentle to avoid any damage. Look for any signs of wear, corrosion, or damage that could have occurred during the vehicle's operation. Documenting the condition of the motor at this stage can be valuable for future reference.

Component Inspection: As you dismantle the motor, inspect each component thoroughly. Check for any signs of overheating, corrosion, or mechanical damage. Look for any loose connections or worn-out parts that may require replacement. Pay attention to the wiring harnesses and ensure they are intact and securely connected. This inspection process is vital to identify potential issues that could affect the motor's performance or longevity.

Documentation and Safety: Throughout the disassembly process, maintain detailed records of the steps taken and any observations made. This documentation will be valuable for future reference and can help in troubleshooting or identifying patterns in motor failures. Ensure that all tools and components are handled with care to prevent any accidents or further damage.

Remember, the key to successful motor disassembly is patience and adherence to the manufacturer's guidelines. This approach ensures that the inspection process is thorough and safe, providing valuable insights into the health of the electric motor.

Unlocking EV Battery Investing: Strategies for a Sustainable Future

You may want to see also

Wiring Harness Extraction: Identify and carefully separate the complex wiring system

When it comes to dismantling an electric vehicle, one of the most intricate and delicate processes is the extraction of the wiring harness. This system is the backbone of the vehicle's electrical network, connecting various components and ensuring the proper functioning of the car. Here's a step-by-step guide on how to carefully separate and identify the wiring harness:

Step 1: Visual Inspection and Documentation

Start by thoroughly examining the wiring harness. Locate the main bundle of wires, often referred to as the 'main harness'. Identify the various sub-harnesses that branch out from the main one, each serving a specific area or component of the vehicle. Document the layout and connections by taking detailed notes or photographs. This step is crucial as it helps you understand the intricate network and ensures you don't accidentally sever important connections.

Step 2: Locate Critical Components

Identify and mark the positions of critical components connected to the wiring harness. These may include the battery, motor control unit, power electronics, sensors, and actuators. Understanding the function of each component will help you decide which parts to prioritize when separating the harness. For instance, the battery might require special attention due to its high voltage and potential hazards.

Step 3: Carefully Cut and Separate

Using sharp and precise cutting tools, carefully sever the wiring harness at strategic points. Start with the sub-harnesses, cutting them off from the main harness while preserving the individual wires. Take your time to avoid damaging the insulation or exposing bare wires. For more delicate connections, consider using a wire cutter or a hot-knife tool to minimize the risk of short circuits. Ensure that you leave enough length on each wire to facilitate proper disposal or potential reuse.

Step 4: Organize and Label

As you separate the wiring harness, organize the wires and components into manageable groups. Label each bundle or section clearly, indicating its original location and function. This organization will make the disposal or recycling process more efficient and safer. Proper labeling also ensures that you can quickly identify and reuse specific wires or components in the future if needed.

Step 5: Handle with Care

Throughout the extraction process, exercise extreme caution to avoid any electrical hazards. Electric vehicles operate at high voltages, and improper handling can lead to short circuits or injuries. Wear appropriate personal protective equipment, such as insulated gloves and safety goggles, to minimize risks. Additionally, ensure that the work area is well-lit and free from flammable materials to prevent accidents.

By following these steps, you can effectively identify and carefully separate the complex wiring system of an electric vehicle, making the scrapping process more efficient and safer. Remember, each vehicle model may have unique wiring configurations, so adapting these steps to the specific make and model is essential.

Unlocking EV Affordability: Strategies for Developing Nations

You may want to see also

Frame Structure: Understand the vehicle's frame to access and remove key components

To begin the process of scrapping an electric vehicle, it's crucial to understand the vehicle's frame structure, as this knowledge will enable you to access and remove key components efficiently. The frame of an electric vehicle is typically a robust and intricate system designed to support the vehicle's weight and provide structural integrity. Here's a step-by-step guide to help you navigate this process:

- Familiarize Yourself with the Vehicle's Anatomy: Start by studying the vehicle's manual or technical specifications. Electric vehicles often have unique frame designs, especially with the placement of batteries and other heavy components. Identify the key areas, including the battery pack, motor, transmission, and any other heavy modules. Understanding the layout will help you plan the removal process.

- Locate the Frame Components: The frame of an electric vehicle is usually composed of various metal panels, beams, and supports. These components are designed to distribute the vehicle's weight and provide rigidity. Identify the main frame rails, crossmembers, and any additional structural elements. Knowing these components will help you locate the access points for removing parts without causing damage.

- Accessing the Frame: To access the internal components, you'll need to carefully remove the exterior panels. This process may involve prying off body panels, removing screws or fasteners, and carefully lifting or cutting away the panels. Take your time and be gentle to avoid damage to the vehicle's interior or other components. Focus on the areas around the battery pack, as this is a critical component that requires precise handling.

- Removing Key Components: Once you have access to the frame, start by disconnecting the electrical connections to the battery pack and other modules. This step is crucial to prevent any short circuits or damage. Then, carefully lift and remove the battery pack, ensuring you follow the manufacturer's guidelines for handling and disposing of the batteries safely. Next, access the motor and transmission by removing any necessary panels or covers, and then disconnect the relevant wiring and fasteners.

- Safety and Precision: Throughout the process, prioritize safety and precision. Electric vehicles have complex systems, and improper handling can lead to accidents or damage. Use the appropriate tools and be cautious when removing components to avoid any hazards. Additionally, consider the environmental impact of your work and ensure you dispose of materials responsibly.

Understanding the frame structure is essential for a successful and safe scrapping process. It allows you to work efficiently, access critical components, and ensure the proper disposal of materials. Remember, each electric vehicle model may have unique characteristics, so always refer to the vehicle's documentation for specific instructions.

Navigating California's EV Battery Warranty: A Step-by-Step Guide to Filing a Complaint

You may want to see also

Recycling Processes: Learn about end-of-life recycling methods for EV materials

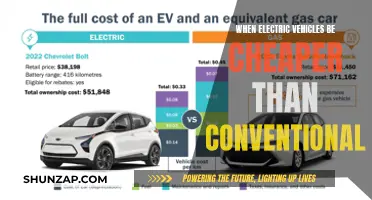

The end-of-life recycling process for electric vehicles (EVs) is a crucial aspect of sustainable transportation, ensuring that valuable materials are recovered and potential environmental impacts are minimized. When an EV reaches the end of its useful life, it can be recycled to extract a variety of materials, contributing to a circular economy. Here's an overview of the recycling processes involved:

- Dismantling and Sorting: The first step in recycling an EV is to carefully dismantle it, separating different components and materials. This process requires skilled technicians who can identify and isolate various parts, including the battery pack, electric motor, wiring, and other electronic systems. The dismantling process is meticulous, ensuring that each component is handled appropriately for subsequent recycling. After dismantling, the materials are sorted into different categories, such as metals, plastics, and electronics.

- Battery Recycling: One of the most critical aspects of EV recycling is the proper handling and recycling of battery packs. Lithium-ion batteries, commonly used in EVs, contain valuable materials like lithium, cobalt, and nickel, as well as potentially hazardous substances. Specialized facilities use advanced techniques to disassemble battery cells, recover cathode and anode materials, and recycle or repurpose them. This process ensures that rare earth metals are reclaimed, reducing the need for mining and minimizing environmental degradation.

- Metal Recycling: EVs are composed of various metals, including aluminum, copper, steel, and rare earth metals. These metals can be recycled and reused in the manufacturing of new vehicles or other products. Metal recycling involves shredding the vehicle's body and components to recover these materials. For example, aluminum and steel can be melted and remolded for use in new car parts or construction materials. Copper wiring can be extracted and sold for reuse in various industries.

- Plastic Recycling: Plastic components in EVs, such as interior panels, wiring harnesses, and exterior panels, can be recycled. Plastic recycling processes vary depending on the type of plastic used. Some plastics can be ground into flakes and then processed into new products, while others may be shredded and combined with new plastic to create new items. Proper recycling of plastics ensures that these materials can be reused in various applications, reducing the demand for virgin plastic production.

- Electronic Waste Management: EVs are equipped with advanced electronic systems, including sensors, control units, and infotainment systems. These electronics contain valuable materials and can be recycled to recover precious metals like gold and silver. Electronic waste (e-waste) recycling facilities use specialized techniques to extract and recycle these materials, ensuring proper disposal of hazardous components.

- End-of-Life Vehicle (ELV) Standards and Regulations: Recycling processes for EVs are often governed by strict regulations and standards to ensure environmental protection and material recovery. Many countries have implemented ELV directives that mandate specific recycling rates and procedures for manufacturers. These regulations encourage the development of efficient recycling infrastructure and promote the responsible end-of-life management of EVs.

In summary, the recycling of electric vehicles involves a comprehensive process of dismantling, sorting, and specialized recycling techniques for various materials. By implementing these methods, valuable resources can be recovered, contributing to a more sustainable approach to EV manufacturing and disposal. As the EV market continues to grow, efficient and environmentally friendly recycling processes will play a vital role in minimizing the environmental impact of these vehicles throughout their lifecycle.

Unlock EV Savings: Your Guide to Electric Vehicle Tax Credits

You may want to see also

Frequently asked questions

Scrapping an EV involves a series of steps to ensure proper disposal and recycling. It typically starts with a thorough inspection to assess the vehicle's condition and identify any potential hazards. Then, specialized equipment is used to safely dismantle the car, separating different components like the battery, motor, and electronics. These parts are then sent for recycling and recovery of valuable materials.

Before scrapping, it's essential to prepare your EV by disconnecting any power sources and ensuring it is in a safe, secure location. Remove any personal belongings and valuable items from the vehicle. You might also want to consider draining the battery to a safe level, especially for older models, to prevent any potential hazards during the dismantling process.

Yes, EV batteries require special handling and disposal methods due to their chemical composition. These batteries should never be thrown in regular waste streams. Specialized recycling facilities can safely extract and recycle the battery's materials, ensuring environmental protection. It's crucial to follow local regulations and guidelines for EV battery disposal.

The recycling process of an EV aims to recover valuable metals and materials. For instance, lithium-ion batteries can be recycled to retrieve metals like cobalt, nickel, and lithium. The motor and electronics may contain precious metals like platinum and palladium. These recovered materials can then be used in various industries, promoting a circular economy and reducing the need for mining new resources.

Absolutely! Many EV owners choose to sell or donate usable parts to keep the vehicle out of the scrapping process. Functional components like the motor, battery, or even the car's body can be valuable to other enthusiasts or businesses. This approach promotes sustainability and can provide financial benefits, allowing you to recover some value from your EV before it's completely dismantled.