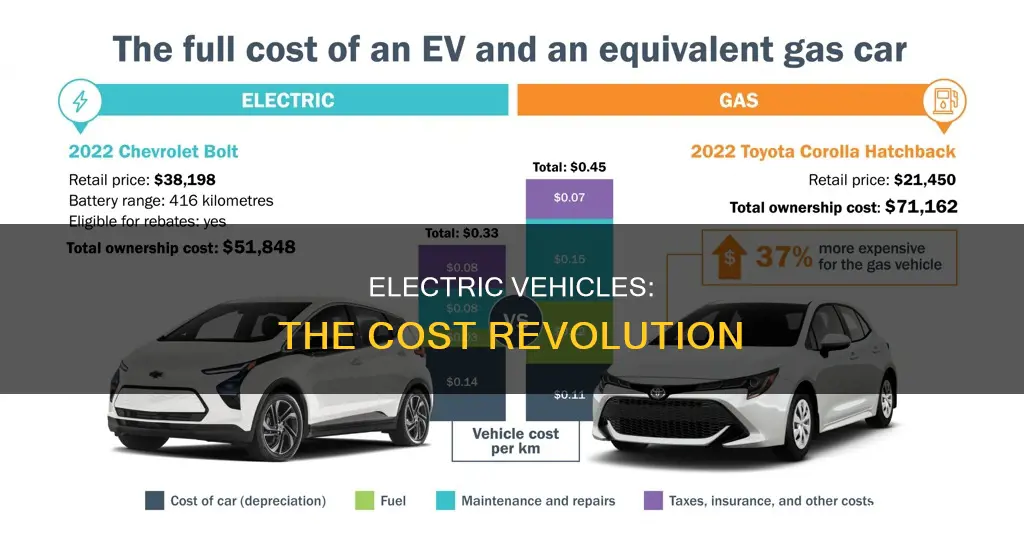

The future of transportation is rapidly approaching as electric vehicles (EVs) become increasingly affordable and accessible. The question on many minds is when the price of EVs will drop to a point where they are cheaper to purchase and own than conventional vehicles. This pivotal moment is not just about the initial cost of the car but also includes the long-term savings on fuel, maintenance, and even insurance. As technology advances and production scales, the cost of batteries and other key components is expected to decrease, making electric cars more competitive in the market. This shift will not only benefit individual consumers but also contribute to a more sustainable and environmentally friendly transportation ecosystem.

What You'll Learn

- Battery Technology: Improved battery efficiency and reduced costs drive EV affordability

- Manufacturing Scale: Mass production lowers EV prices, making them competitive with traditional cars

- Market Competition: Increased competition among EV manufacturers leads to price drops

- Government Incentives: Tax credits and subsidies make EVs more accessible and affordable

- Technological Advancements: Innovations in materials and design reduce EV production costs

Battery Technology: Improved battery efficiency and reduced costs drive EV affordability

The rapid advancement in battery technology is a key factor in the ongoing journey towards making electric vehicles (EVs) more affordable and accessible to the masses. Improved battery efficiency and reduced costs are driving forces behind the growing popularity of EVs, challenging the dominance of conventional internal combustion engine (ICE) vehicles.

Battery efficiency has seen remarkable progress, primarily through innovations in materials science and manufacturing processes. One significant development is the use of lithium-ion batteries, which have become the standard for EVs due to their high energy density and relatively low cost. Researchers and engineers are now focusing on enhancing the performance of these batteries by increasing their energy storage capacity while reducing the weight and volume they occupy. This involves the development of advanced cathode and anode materials, such as nickel-manganese-cobalt (NMC) and lithium-rich layered oxides, which offer higher energy densities compared to traditional lithium-cobalt-oxide (LCO) batteries.

Another critical aspect of improving battery efficiency is extending the vehicle's range. This is achieved by optimizing the battery's charge-discharge cycles, implementing more efficient power electronics, and adopting smart energy management systems. These systems can monitor and adjust power distribution, ensuring that the battery operates at its most efficient level, thereby maximizing the vehicle's range on a single charge. For instance, regenerative braking systems capture and store energy that would otherwise be lost during braking, contributing to a more efficient overall driving experience.

Reducing battery costs is equally important in making EVs more affordable. The cost of lithium-ion batteries has already decreased significantly over the years, and further reductions are being pursued through various strategies. One approach is to streamline manufacturing processes, including the automation of assembly lines and the optimization of raw material sourcing. This not only reduces production costs but also minimizes waste, making the manufacturing process more sustainable. Additionally, researchers are exploring alternative battery chemistries that could offer higher energy densities and lower production costs, such as solid-state batteries and redox flow batteries.

The combination of improved battery efficiency and reduced costs has a direct impact on EV affordability. As battery technology advances, EVs become more competitive in terms of price compared to conventional vehicles. This is particularly evident in the mass production of EVs, where economies of scale drive down costs. With each new generation of EVs, manufacturers can produce more vehicles at lower prices, making them more accessible to a broader consumer base. Moreover, the declining cost of batteries allows for the integration of additional features and technologies, enhancing the overall driving experience and further increasing the appeal of electric vehicles.

India's Electric Revolution: Are We Charged and Ready?

You may want to see also

Manufacturing Scale: Mass production lowers EV prices, making them competitive with traditional cars

The concept of electric vehicles (EVs) becoming cost-competitive with conventional internal combustion engine (ICE) cars is gaining traction, and one of the key factors driving this trend is manufacturing scale. As the demand for EVs increases, manufacturers are able to streamline production processes, reduce costs, and ultimately make electric cars more affordable for consumers.

Mass production of EVs has led to significant economies of scale. When a manufacturer produces a large volume of a particular EV model, the cost of production per unit decreases. This is because fixed costs, such as research and development, tooling, and infrastructure, are spread across a higher number of vehicles. As a result, the price per EV unit drops, making it more financially viable for consumers to purchase electric cars. For instance, the Tesla Model 3, one of the most popular EVs, has seen its price decrease over time due to increased production volumes, making it a more attractive option compared to many conventional cars in the same segment.

Another aspect of manufacturing scale is the optimization of supply chains and component sourcing. With higher production volumes, manufacturers can negotiate better deals with suppliers, ensuring a steady supply of raw materials and components at lower costs. This includes batteries, which are a significant component of EVs and often contribute to a large portion of the vehicle's overall cost. As manufacturers secure better prices for batteries and other parts, the overall production cost of EVs decreases, making them more price-competitive with traditional cars.

Furthermore, mass production allows for process improvements and technological advancements. Manufacturers can invest in research and development to enhance production techniques, improve quality control, and reduce waste. This includes the implementation of automated assembly lines, advanced robotics, and efficient manufacturing processes. By optimizing these aspects, EV manufacturers can lower production times, increase efficiency, and ultimately reduce the cost of manufacturing, which is then passed on to consumers in the form of lower prices.

The impact of manufacturing scale on EV prices is already being felt in the market. As more car manufacturers enter the electric vehicle space and production volumes increase, we are witnessing a rapid decline in EV prices. This trend is expected to continue as technology improves, and economies of scale become more pronounced. With conventional cars still carrying a higher price tag, the race to make EVs affordable is on, and manufacturing scale is a critical factor in achieving this goal.

Powering Electric Vehicles: Understanding the Battery Management System

You may want to see also

Market Competition: Increased competition among EV manufacturers leads to price drops

The market dynamics surrounding electric vehicles (EVs) are rapidly evolving, and one of the key factors driving this transformation is the increasing competition among EV manufacturers. As more companies enter the EV space, the market becomes more saturated, leading to a natural outcome: price wars. This competitive environment is a significant contributor to the growing affordability of electric vehicles, making them a more attractive and viable alternative to conventional gasoline-powered cars.

In a highly competitive market, each manufacturer aims to differentiate its products and gain a competitive edge. This often involves reducing production costs and, subsequently, the selling prices of their EVs. With a wide range of options available, consumers benefit from a diverse selection of models, features, and price points. This diversity encourages manufacturers to innovate, improve efficiency, and drive down costs to remain competitive. As a result, the overall price of EVs has been steadily decreasing, making them more accessible to a broader audience.

The increased competition has led to a race to the bottom in terms of pricing, especially in the mass-market segment. Established automakers and new entrants alike are vying for market share, and one of the most effective strategies to achieve this is by offering competitive prices. This has resulted in a downward pressure on EV prices, forcing manufacturers to re-evaluate their production processes and supply chains to reduce costs further. For instance, economies of scale come into play as manufacturers produce more vehicles, allowing them to negotiate better deals with suppliers and reduce per-unit production costs.

Additionally, the competitive market encourages manufacturers to focus on cost-saving measures in various aspects of their operations. This includes optimizing battery technology, improving manufacturing processes, and streamlining supply chains. For example, advancements in battery chemistry and design have led to more efficient and cost-effective energy storage solutions, which are then reflected in lower vehicle prices. Similarly, efficient manufacturing processes and the adoption of automation can reduce labor costs and increase production speed, ultimately contributing to reduced vehicle prices.

As the market competition intensifies, consumers can expect to see even more significant price drops in the future. With a growing number of players in the EV space, the pressure to offer competitive pricing will persist. This trend is likely to continue as the technology matures and the market becomes more established, ultimately benefiting consumers who will have access to a wider range of affordable electric vehicles. The increased competition among EV manufacturers is, therefore, a powerful force driving the price reduction of electric vehicles, making them a more accessible and economically viable choice for the masses.

The Future of Transportation: When Will All Vehicles Go Electric?

You may want to see also

Government Incentives: Tax credits and subsidies make EVs more accessible and affordable

Government incentives play a crucial role in promoting the adoption of electric vehicles (EVs) and making them more affordable for consumers. One of the primary methods used by governments to encourage the shift towards EVs is through financial incentives, such as tax credits and subsidies. These incentives are designed to reduce the upfront cost of purchasing EVs, making them more accessible to a wider range of consumers.

Tax credits are a popular incentive strategy. When a government offers a tax credit for EV purchases, it directly reduces the amount of tax owed by the buyer. This can be a significant financial benefit, especially for those in higher tax brackets. For instance, a government might provide a tax credit of $5,000 for the purchase of an electric car, which can substantially lower the overall cost for the buyer. This incentive not only makes EVs more affordable but also encourages consumers to consider electric options over conventional vehicles.

Subsidies are another powerful tool in the government's arsenal to promote EV adoption. These subsidies often come in the form of direct financial assistance or grants to manufacturers and consumers. For manufacturers, subsidies can help cover the higher production costs associated with EVs, encouraging more companies to invest in and produce electric vehicles. This increased production can lead to economies of scale, driving down the overall cost of EVs. Consumers, on the other hand, may receive subsidies in the form of reduced registration fees, lower license plate costs, or even cash rebates when they purchase an EV. These subsidies can make the initial investment in an electric vehicle more manageable, especially for those on a tighter budget.

The combination of tax credits and subsidies creates a compelling financial argument for consumers to choose EVs over conventional cars. By significantly reducing the purchase price and ongoing costs, governments can make EVs more attractive and competitive in the market. This approach not only benefits individual consumers but also contributes to a larger environmental goal by encouraging the transition to cleaner transportation methods.

In summary, government incentives in the form of tax credits and subsidies are essential in bridging the price gap between electric and conventional vehicles. These incentives make EVs more affordable, accessible, and desirable to a broader audience, ultimately accelerating the adoption of electric transportation and fostering a more sustainable future.

Trump's Electric Vehicle Critics: A Green Revolution or a Threat?

You may want to see also

Technological Advancements: Innovations in materials and design reduce EV production costs

The rapid evolution of electric vehicles (EVs) is driven by a multitude of technological advancements, with a significant focus on reducing production costs. One of the key areas of innovation is materials science, where researchers are constantly exploring new and more efficient materials for EV components. For instance, the development of lightweight, high-strength batteries is crucial for improving energy density and reducing overall vehicle weight. Scientists are experimenting with novel materials like silicon-based anodes, which offer higher energy storage capacity compared to traditional graphite anodes, and solid-state electrolytes, which promise faster charging and higher safety levels. These advancements not only enhance the performance of EVs but also contribute to cost reduction by minimizing the amount of expensive materials required.

Design innovations are also playing a pivotal role in making EVs more affordable. Engineers are employing advanced manufacturing techniques, such as 3D printing and automated assembly lines, to streamline production processes. These methods enable the creation of complex, lightweight structures with minimal material waste, reducing both production time and costs. Additionally, the integration of artificial intelligence (AI) and machine learning algorithms in design software allows for rapid prototyping and optimization, ensuring that every component is designed with efficiency and cost-effectiveness in mind.

Another significant development is the use of sustainable and recycled materials in EV manufacturing. Automotive manufacturers are increasingly adopting recycled plastics and metals, which not only reduces the reliance on virgin resources but also lowers production costs. For example, recycled lithium-ion batteries can be reprocessed and used as raw materials for new batteries, reducing the need for expensive extraction processes. This circular economy approach not only benefits the environment but also contributes to the long-term sustainability and cost-effectiveness of EV production.

Furthermore, the design of EVs is becoming more modular, allowing for easier customization and maintenance. Modular designs enable the separation of individual components, making it simpler to upgrade or replace specific parts without replacing the entire vehicle. This not only reduces the overall cost of ownership but also extends the lifespan of the EV, as components can be repaired or replaced as needed, rather than replaced en masse.

In summary, the continuous advancements in materials and design are pivotal in driving down the production costs of electric vehicles. Through the development of innovative materials, efficient manufacturing processes, sustainable practices, and modular designs, the EV industry is making significant strides towards making electric transportation more accessible and affordable for the masses. These technological breakthroughs are essential in the journey towards a future where EVs are not only environmentally friendly but also economically viable alternatives to conventional vehicles.

Unveiling the Materials: Inside Electric Vehicle Construction

You may want to see also

Frequently asked questions

The cost of electric vehicles has been decreasing steadily over the years, and it's expected that this trend will continue. Many experts predict that by 2025, EVs will be cost-competitive with conventional gasoline or diesel cars, especially with the potential for lower running costs and government incentives.

The primary factor is the battery technology and its associated costs. As battery production scales up and becomes more efficient, the price per kilowatt-hour of battery capacity decreases. Additionally, the increasing demand for EVs is driving innovation and economies of scale, which further reduces prices.

Consumers can take advantage of various incentives and rebates offered by governments to promote EV adoption. These may include tax credits, reduced registration fees, and even subsidies for purchasing electric vehicles. Researching and comparing different models, considering used EV options, and taking advantage of lease programs can also make EVs more affordable.

Absolutely! EVs have lower fuel and maintenance costs over their lifetime. Electricity is generally cheaper than gasoline or diesel, and electric motors have fewer moving parts, resulting in reduced maintenance expenses. Additionally, the value of EVs tends to depreciate slower than conventional cars, making them a more cost-effective long-term investment.