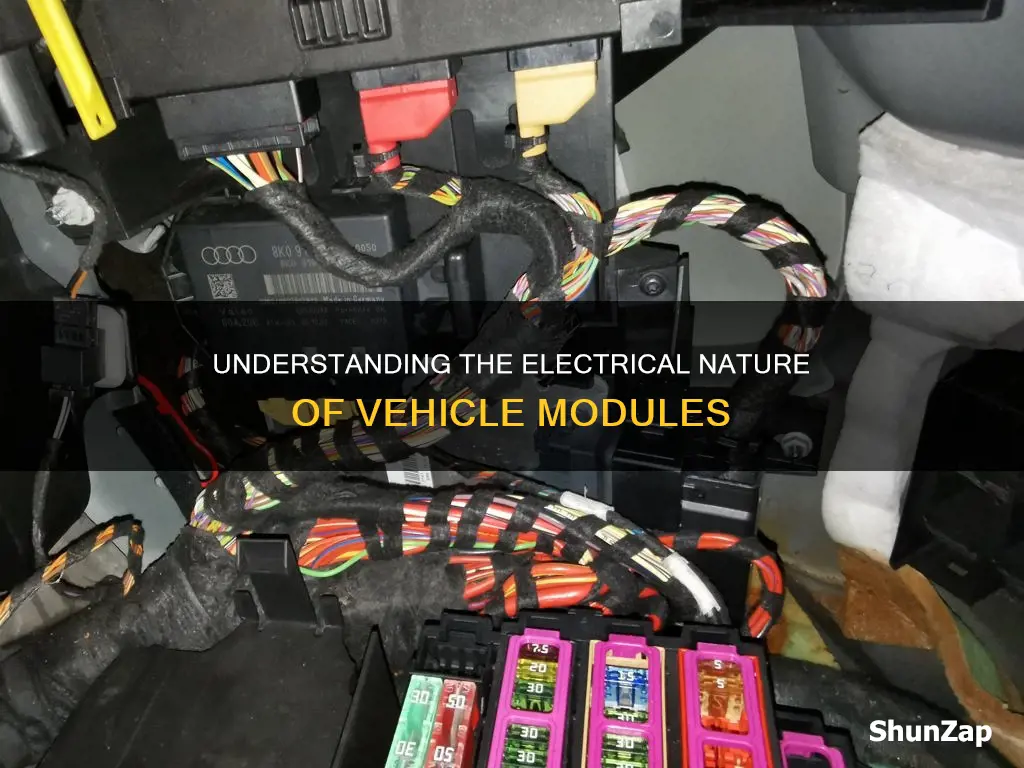

The question of whether a module on a vehicle is considered an electrical component is an important one, especially in the context of vehicle maintenance and repair. Electrical components are integral to modern vehicles, powering everything from the engine to the dashboard displays. Modules, which are essentially electronic control units (ECUs) that manage and control various vehicle functions, are a crucial part of this electrical system. Understanding the electrical nature of these modules is key to diagnosing and fixing issues related to vehicle performance, safety, and comfort. This module-based approach to vehicle design has led to more efficient and sophisticated automotive systems, making the classification of these components as electrical parts even more significant.

| Characteristics | Values |

|---|---|

| Definition | A module on a vehicle is typically an electronic assembly that contains one or more electronic components and is designed to perform a specific function or control a particular system. |

| Electrical Nature | Yes, a vehicle module is generally considered an electrical component as it relies on electricity to function and control various parts of the vehicle's systems. |

| Functionality | Modules can include sensors, actuators, control units, communication interfaces, and more, all of which are electrical in nature. |

| Power Source | Modules draw power from the vehicle's electrical system, often through wiring harnesses and connectors. |

| Integration | They are often integrated into the vehicle's architecture, providing a compact and efficient way to manage and control various functions. |

| Examples | Engine control modules, transmission control units, ABS modules, airbag control units, and infotainment systems. |

| Regulation | Electrical components, including vehicle modules, are often subject to regulations and standards to ensure safety and performance. |

| Maintenance | Proper maintenance and diagnosis of electrical components, such as modules, require specialized tools and knowledge of vehicle electronics. |

What You'll Learn

- Definition: Modules are electronic assemblies that control vehicle functions, often containing sensors and actuators

- Power Source: Electrical power is supplied to modules via wiring harnesses and fuses

- Communication: Modules communicate with the vehicle's central computer using CAN bus or similar protocols

- Diagnostics: Modern modules can be diagnosed using OBD-II ports or specialized tools for fault codes

- Reliability: Proper installation and maintenance ensure modules function reliably, preventing electrical failures

Definition: Modules are electronic assemblies that control vehicle functions, often containing sensors and actuators

Modules are integral components of modern vehicles, playing a crucial role in controlling and managing various functions. These electronic assemblies are designed to perform specific tasks, often involving the interaction between sensors and actuators. In simple terms, a module is a compact unit that houses electronic circuits, microcontrollers, and other components, all working together to ensure the vehicle's smooth operation.

Within a vehicle's intricate network, modules act as the brain, making decisions and coordinating actions. They receive input from sensors, which detect various parameters like speed, temperature, or engine performance. These sensors provide critical data, allowing the module to make informed decisions and trigger appropriate responses. For instance, a module might control the fuel injection system, adjusting the fuel flow based on engine speed and load, ensuring optimal performance and fuel efficiency.

The design of these modules often includes actuators, which are mechanical components that convert electronic signals into physical actions. For example, an actuator might be responsible for adjusting the vehicle's suspension, changing the tire pressure, or operating the power steering system. By integrating sensors and actuators, modules enable precise control over these functions, enhancing the overall driving experience and vehicle safety.

In the context of vehicle maintenance and repairs, understanding the role of modules is essential. When a vehicle's function is compromised, it often indicates an issue with one or more modules. Technicians use diagnostic tools to communicate with these modules, retrieving error codes and data to identify the problem. This process allows for efficient troubleshooting and targeted repairs, ensuring the vehicle's electrical system remains in optimal condition.

Furthermore, the development of advanced driver-assistance systems (ADAS) has further emphasized the importance of modules. ADAS features like adaptive cruise control, lane-keeping assist, and automatic emergency braking rely on sophisticated modules to process sensor data and make split-second decisions. These modules are at the forefront of vehicle technology, contributing to improved safety and driving convenience.

Unlocking EV Affordability: Strategies for Developing Nations

You may want to see also

Power Source: Electrical power is supplied to modules via wiring harnesses and fuses

Electrical power is the lifeblood of any vehicle's modern systems, and it is distributed through a complex network of wiring harnesses and fuses to various modules and components. These harnesses are essentially bundles of wires that carry electrical signals and power from the vehicle's battery or alternator to the different parts that need it. Each harness is carefully designed to ensure that the correct voltage and current reach the intended destinations, allowing for the proper functioning of various modules.

The wiring harnesses are typically color-coded and labeled to make identification and installation easier. They are designed to be robust and flexible, capable of withstanding the rigors of the automotive environment, including vibrations, temperature fluctuations, and exposure to various chemicals. The harnesses are also often protected by insulation and shielding to prevent electrical interference and ensure the reliability of the power supply.

Fuses play a critical role in this system, acting as safety devices to protect the wiring and electrical components from potential damage caused by excessive current. They are strategically placed along the wiring harnesses and are designed to melt and break the circuit if the current exceeds a safe level. This prevents overheating, short circuits, and potential fires, making it an essential safety feature in vehicles.

When a module requires power, it connects to the wiring harness via specific terminals or connectors. These connections are designed to ensure a secure and reliable power supply while also allowing for easy maintenance and repairs. The fuses are often located close to the modules they protect, providing a quick and effective response to any potential issues.

In summary, the power source for vehicle modules is a well-organized and intricate system. Wiring harnesses and fuses work together to deliver electrical power efficiently and safely, ensuring that each module receives the necessary energy to function as intended. This setup is a testament to the sophisticated engineering that goes into modern vehicles, where every component, no matter how small, plays a vital role in the overall performance and safety of the automobile.

Unlock Massachusetts EV Tax Savings: A Comprehensive Guide

You may want to see also

Communication: Modules communicate with the vehicle's central computer using CAN bus or similar protocols

In modern vehicles, various modules are integral components that facilitate specific functions and systems. These modules are designed to communicate with the vehicle's central computer, often referred to as the Engine Control Unit (ECU) or the Vehicle Control Module (VCM). Effective communication between these modules and the central computer is crucial for the overall performance, safety, and efficiency of the vehicle. This communication is primarily achieved through a network known as the Controller Area Network (CAN) bus, which is a widely used protocol in automotive applications.

The CAN bus is a robust and reliable communication system that enables modules to exchange data and instructions. It operates on a network of nodes, where each node represents a vehicle module. These nodes transmit and receive data packets, ensuring that all connected modules receive the necessary information to function correctly. The protocol defines specific rules and timing for data transmission, allowing for efficient and synchronized communication throughout the vehicle.

Modules in a vehicle can vary widely, including engine control modules, transmission control modules, anti-lock braking system (ABS) modules, airbag control modules, and infotainment system modules, among others. Each module has its own set of responsibilities, such as monitoring engine performance, controlling gear shifts, managing braking systems, or operating entertainment features. To ensure seamless operation, these modules must communicate their respective data and commands to the central computer using the CAN bus protocol.

When a module detects an issue or requires specific instructions, it transmits a message over the CAN bus. This message contains relevant data, such as error codes, sensor readings, or control signals. The central computer, acting as the master node, receives these messages and processes the information accordingly. It then sends appropriate responses or commands back to the respective modules, allowing for real-time adjustments and optimizations. This two-way communication ensures that the vehicle's systems work in harmony, providing a smooth and safe driving experience.

The use of CAN bus and similar communication protocols in vehicles has revolutionized the automotive industry. It enables advanced features like electronic stability control, adaptive cruise control, and automated parking assistance. These systems rely on the seamless communication between various modules and the central computer. As vehicle technology continues to evolve, the importance of efficient communication protocols like CAN bus will only increase, further enhancing the capabilities and safety of modern automobiles.

Maximizing Massachusetts EV Tax Benefits: A Comprehensive Guide

You may want to see also

Diagnostics: Modern modules can be diagnosed using OBD-II ports or specialized tools for fault codes

Modern vehicles are equipped with an array of electronic modules, each controlling specific functions and systems. These modules are integral to the vehicle's performance and can often be the source of various issues. Diagnosing these modules is crucial for mechanics and car enthusiasts alike, and there are several methods to achieve this. One of the most common and accessible ways to diagnose these modules is through the On-Board Diagnostics (OBD-II) port.

The OBD-II port is a standardized diagnostic interface found in most vehicles manufactured since 1996. It allows mechanics and car owners to connect a diagnostic tool or scanner to the vehicle's onboard computer system. By accessing the OBD-II port, you can retrieve real-time data, view diagnostic trouble codes (DTCs), and monitor various vehicle parameters. This method is user-friendly and often provides immediate insights into the vehicle's health. When a module malfunction occurs, it triggers a fault code, which is stored in the vehicle's computer. These fault codes are essentially error messages that indicate the specific issue with a particular module.

OBD-II scanners are readily available and can be connected to the port to read these fault codes. The scanner then translates the codes into understandable messages, allowing users to identify the problem. For instance, a fault code related to the engine control module might indicate an issue with fuel injection, sensor readings, or ignition timing. This information is invaluable for mechanics, as it narrows down the potential causes and guides the repair process.

In addition to OBD-II ports, specialized tools are also used for module diagnostics. These tools often provide more advanced features and can offer a more comprehensive diagnosis. They may include functions such as live data streaming, which displays real-time sensor data, and advanced scanning capabilities that can read and clear fault codes. Specialized tools might also have the ability to communicate with individual modules, allowing for more precise testing and calibration.

Using these diagnostic methods, mechanics can efficiently identify and resolve issues related to vehicle modules. Whether it's through the OBD-II port or specialized tools, the process involves connecting the diagnostic equipment, retrieving fault codes, and interpreting the results. This approach not only saves time but also ensures that the root cause of the problem is accurately identified, leading to more effective and targeted repairs.

Securing Autopilot: Preventing the Theft of Electric Vehicles

You may want to see also

Reliability: Proper installation and maintenance ensure modules function reliably, preventing electrical failures

The reliability of vehicle modules is a critical aspect of automotive engineering, ensuring the safe and efficient operation of modern vehicles. Proper installation and maintenance practices are essential to guarantee that these components function reliably and prevent electrical failures, which can lead to costly repairs and potential safety hazards.

When installing vehicle modules, it is crucial to follow manufacturer guidelines and best practices. Each module has specific requirements for placement, wiring connections, and mounting techniques. For instance, some modules might need to be mounted in a way that provides adequate ventilation to prevent overheating, while others may require specific types of connectors to ensure a secure and reliable connection. Adhering to these instructions is vital, as improper installation can lead to issues such as poor signal transmission, incorrect voltage regulation, or even physical damage to the module.

Regular maintenance is another key factor in ensuring module reliability. Over time, vehicle modules can experience degradation due to various factors like extreme temperatures, vibration, and corrosion. Routine inspections and maintenance routines should include checking for any signs of damage, corrosion, or loose connections. For example, examining the module's wiring harness for any frayed or damaged wires, ensuring that all connections are secure and free from corrosion, and verifying that the module is not overheating during operation. By addressing these potential issues proactively, vehicle owners can prevent electrical failures and maintain the overall performance and longevity of their vehicles.

Furthermore, keeping the vehicle's electrical system clean and well-maintained is essential. Dirt, dust, and moisture can accumulate around modules, especially in areas with poor ventilation or frequent exposure to the elements. This buildup can lead to insulation breakdown, short circuits, or improper module function. Regular cleaning and sealing of module connections, as well as ensuring that the vehicle's electrical system is protected from environmental contaminants, are simple yet effective measures to enhance reliability.

In summary, the reliability of vehicle modules is paramount for the safe and efficient operation of modern vehicles. Proper installation, following manufacturer guidelines, and regular maintenance are essential practices to ensure these electrical components function reliably. By addressing potential issues and providing adequate care, vehicle owners can prevent electrical failures, maintain optimal performance, and extend the lifespan of their vehicles' modules.

Troubleshooting Electrical Issues: A Comprehensive Guide to Diagnosing Vehicle Problems

You may want to see also

Frequently asked questions

Yes, a module on a vehicle is indeed an electrical component. Modules are typically electronic devices that control and manage specific functions or systems within a vehicle's electrical architecture. They are designed to receive input signals, process data, and output commands to various actuators or sensors, all of which rely on electrical power and signals to function.

Vehicle modules often have more complex functionality compared to standard electrical components. They are designed to handle specific tasks, such as engine control, transmission management, climate control, or entertainment systems. These modules are integrated into the vehicle's network, communicating with other modules and the central computer system to ensure proper operation and coordination.

Absolutely. Vehicle modules can be replaced or upgraded, especially if they malfunction or become obsolete. Modern vehicles often have diagnostic ports that allow mechanics to access the vehicle's computer system and identify any issues with the modules. Upgrading a module can improve performance, add new features, or fix software-related problems.

No, different vehicle modules may have varying power requirements and sources. Some modules might draw power directly from the vehicle's battery, while others may have dedicated power supplies or receive power through specific wiring harnesses. The electrical architecture of a vehicle is designed to accommodate these diverse power needs.

Vehicle modules play a crucial role in optimizing performance and ensuring the safe operation of a vehicle. They help regulate engine speed, control fuel injection, manage emissions, monitor sensor data, and coordinate various systems. By processing and interpreting data, these modules enable vehicles to respond efficiently, provide feedback to the driver, and maintain optimal performance under different conditions.