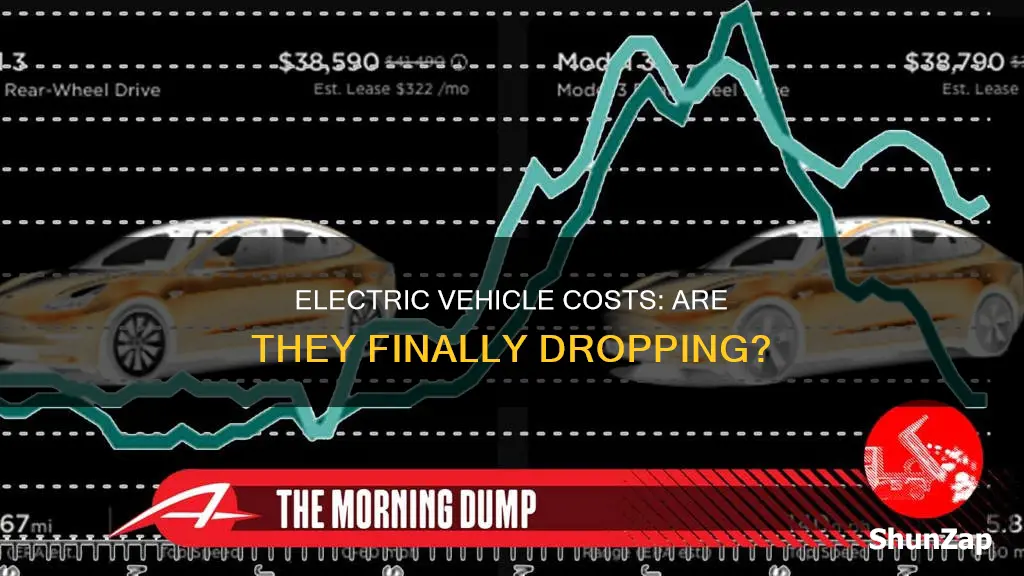

The cost of electric vehicles (EVs) has been a significant barrier to their widespread adoption, but recent trends suggest that this is changing. Over the past few years, advancements in technology and increased production volumes have led to a steady decline in the prices of EVs, making them more accessible to a broader market. This shift is particularly notable in the automotive industry, where electric cars are now competing more directly with traditional internal combustion engine vehicles. The falling cost of EVs is a crucial development in the global transition to sustainable transportation, as it addresses a key concern for potential buyers and accelerates the shift towards a greener future. This paragraph introduces the topic by highlighting the decreasing cost of electric vehicles and its potential impact on the automotive market and environmental sustainability.

| Characteristics | Values |

|---|---|

| Market Trend | The cost of electric vehicles (EVs) has been steadily decreasing over the past decade, with a significant drop in prices observed in 2022. |

| Battery Technology | Advances in battery chemistry and manufacturing processes have led to improved energy density, reduced costs, and longer battery life. |

| Scale of Production | Mass production of EVs has driven down costs due to economies of scale, with manufacturers benefiting from lower material and production expenses. |

| Government Incentives | Many governments worldwide offer subsidies, tax credits, and incentives to promote EV adoption, further reducing the overall cost for consumers. |

| Supply Chain Optimization | Optimized supply chains and reduced reliance on rare earth minerals have contributed to cost savings in EV production. |

| Competition | Increased competition among EV manufacturers has led to price wars, with companies offering more affordable models to gain market share. |

| Used Market | The growing used EV market provides more affordable options for consumers, as older models become more accessible and cost-effective. |

| Charging Infrastructure | The development of charging networks and the reduction in charging times have made EVs more convenient and attractive to potential buyers. |

| Environmental Benefits | While not a direct cost factor, the environmental impact of EVs is a driving force behind their adoption, potentially influencing long-term cost reductions. |

| Future Projections | Industry analysts predict that the cost of EVs will continue to decline, making them more accessible to a wider range of consumers in the coming years. |

What You'll Learn

- Battery Technology: Advances in battery chemistry and design reduce EV costs

- Manufacturing Efficiency: Streamlined production processes lower production expenses

- Supply Chain Optimization: Improved supply chain management reduces raw material costs

- Government Incentives: Tax credits and subsidies make EVs more affordable

- Market Competition: Increased competition drives down prices and encourages innovation

Battery Technology: Advances in battery chemistry and design reduce EV costs

The cost of electric vehicles (EVs) has been a significant barrier to their widespread adoption, but recent advancements in battery technology are driving down these costs and making EVs more accessible to the masses. One of the primary focuses of EV manufacturers and researchers is to improve battery chemistry and design, which has led to substantial progress in reducing the overall cost of EVs.

Battery chemistry plays a crucial role in determining the performance and cost of EV batteries. Traditional lithium-ion batteries, which are currently the most common type used in EVs, have been the subject of extensive research to optimize their chemistry. Scientists and engineers are exploring new cathode materials, such as nickel-rich cathodes, which offer higher energy density and lower production costs compared to traditional cobalt-based cathodes. By utilizing more abundant and less expensive elements, these advancements aim to reduce the overall battery cost while maintaining or even improving performance.

In addition to cathode materials, advancements in anode technology are also contributing to cost reduction. Silicon-based anodes, for instance, have gained attention due to their high theoretical capacity. However, silicon anodes have faced challenges related to volume expansion during charging and discharging cycles. Researchers are now developing innovative designs, such as silicon nanowires or porous silicon structures, to address these issues. These new anode materials and designs can enhance the battery's cycle life, reduce waste, and ultimately lower the cost per kilowatt-hour of energy storage.

Battery design is another critical aspect of reducing EV costs. Engineers are working on optimizing the battery pack layout and architecture to increase energy density and reduce material waste. This includes developing more efficient cooling systems to manage heat dissipation, which is essential for maintaining battery performance and longevity. Furthermore, advancements in manufacturing processes, such as the adoption of automated assembly lines and the use of more sustainable materials, contribute to cost savings and improved production efficiency.

The combination of improved battery chemistry and innovative design concepts is resulting in more efficient and cost-effective EV batteries. These advancements not only benefit EV manufacturers by reducing production costs but also provide consumers with more affordable and high-performance electric vehicles. As battery technology continues to evolve, we can expect further reductions in EV costs, making them a more viable and attractive transportation option for a broader range of consumers. This progress in battery technology is a key driver in the ongoing efforts to make electric mobility more accessible and sustainable.

Maximize Your EV Tax Credit: A Step-by-Step Guide to Reporting

You may want to see also

Manufacturing Efficiency: Streamlined production processes lower production expenses

The cost of electric vehicles (EVs) has been a topic of interest for both consumers and manufacturers, and there are several factors contributing to the trend of falling prices. One significant aspect is the improvement in manufacturing efficiency, which plays a crucial role in reducing production expenses. Streamlined production processes are at the heart of this efficiency gain.

Manufacturers are adopting advanced technologies and automation to optimize their assembly lines. For instance, the use of robotics and automated guided vehicles (AGVs) has revolutionized the automotive industry. These machines can perform repetitive tasks with precision and speed, reducing human error and increasing overall productivity. By automating certain processes, manufacturers can minimize labor costs and improve the consistency of vehicle production.

Streamlining also involves re-engineering production methods to eliminate waste and reduce time. This includes implementing just-in-time inventory systems, where raw materials and components are delivered precisely when needed, minimizing storage costs and reducing the risk of obsolescence. Additionally, manufacturers are focusing on modular design, allowing for easier customization and faster assembly, which can lead to significant cost savings.

Another strategy is the consolidation of production facilities. By centralizing manufacturing operations, companies can optimize logistics, reduce transportation costs, and improve overall efficiency. This approach also enables better control over the supply chain, ensuring a steady supply of components and reducing the chances of production delays.

In summary, the cost of electric vehicles is decreasing due to a combination of factors, with manufacturing efficiency being a key driver. Streamlined production processes, including automation, waste reduction, and optimized logistics, contribute to lower production expenses. As these efficiency measures continue to evolve, we can expect further cost reductions, making electric vehicles more accessible and affordable for consumers worldwide.

India's Electric Revolution: Are We Charged and Ready?

You may want to see also

Supply Chain Optimization: Improved supply chain management reduces raw material costs

The cost of electric vehicles (EVs) has been a topic of interest and concern for both consumers and manufacturers. While the initial price tag of EVs was often higher compared to traditional internal combustion engine (ICE) vehicles, recent trends indicate a positive shift. The question of whether the cost of EVs is falling is indeed relevant, and it's worth exploring the factors that contribute to this potential decrease.

One significant aspect is supply chain optimization, which plays a crucial role in reducing raw material costs. Improved supply chain management can lead to more efficient processes, better cost control, and ultimately, lower prices for consumers. Here's how this optimization can contribute to the cost reduction of electric vehicles:

Streamlined Sourcing and Procurement: Effective supply chain management involves strategic sourcing and procurement practices. By optimizing the supply chain, manufacturers can identify and secure raw materials at more competitive prices. This includes negotiating contracts with suppliers, ensuring a steady supply of essential components, and potentially reducing the overall cost of production. For instance, companies might focus on local or regional suppliers to minimize transportation costs and establish long-term partnerships to benefit from volume-based discounts.

Inventory Management and Waste Reduction: Efficient inventory management is another critical aspect of supply chain optimization. By implementing just-in-time inventory systems, manufacturers can reduce the holding costs associated with excess stock. This approach minimizes the risk of raw material waste and ensures that resources are utilized efficiently. Additionally, with improved inventory management, companies can quickly respond to market demands, reducing the need for costly last-minute procurement and potential price hikes.

Process Optimization and Quality Control: Supply chain optimization also involves refining manufacturing processes and enhancing quality control measures. By streamlining production, manufacturers can reduce the time and resources required to produce each vehicle. This efficiency can lead to cost savings, especially when combined with the right quality control practices. Implementing advanced manufacturing techniques, such as automation and lean manufacturing, can further reduce labor costs and minimize defects, resulting in a more cost-effective production process.

Logistics and Distribution: Optimizing the logistics and distribution network is essential to reducing transportation and delivery costs. This includes implementing efficient routing strategies, utilizing data-driven decision-making, and potentially exploring alternative transportation methods. By minimizing transportation expenses, manufacturers can contribute to the overall cost reduction of EVs. Additionally, efficient distribution ensures that vehicles reach dealerships or customers promptly, reducing the time and associated costs of holding inventory.

In summary, supply chain optimization, with its focus on improved management, sourcing, inventory control, and process efficiency, has the potential to significantly impact the cost of electric vehicles. As manufacturers continue to refine their supply chains, we may witness a continued decrease in the prices of EVs, making them more accessible and competitive in the market. This optimization strategy not only benefits consumers but also contributes to the long-term sustainability and growth of the electric vehicle industry.

Parking Privileges: Unlocking Free EV Parking Benefits

You may want to see also

Government Incentives: Tax credits and subsidies make EVs more affordable

The rising popularity of electric vehicles (EVs) is closely tied to the decreasing cost of these vehicles, which has been significantly influenced by government incentives. Tax credits and subsidies play a crucial role in making EVs more affordable for consumers, thereby encouraging the widespread adoption of electric transportation.

One of the primary ways governments stimulate the EV market is through tax credits. These credits directly reduce the purchase price of electric vehicles, making them more accessible to a broader range of consumers. For instance, many countries offer tax credits that can be substantial, often covering a significant percentage of the vehicle's cost. In the United States, the federal government provides a tax credit of up to $7,500 for the purchase of new electric cars, which can significantly lower the upfront cost for buyers. This incentive not only makes EVs more affordable but also accelerates the transition to electric mobility.

Subsidies are another powerful tool in the government's arsenal to promote EV adoption. These subsidies can take various forms, such as direct financial support, grants, or reduced registration fees. For example, some governments offer subsidies that cover a portion of the vehicle's price, effectively lowering the out-of-pocket expense for consumers. In certain regions, subsidies may also include incentives for the installation of home charging stations, further reducing the overall cost of ownership. By providing these subsidies, governments aim to make EVs more attractive and financially viable for potential buyers.

The impact of these government incentives is twofold. Firstly, they directly lower the financial barrier to entry for EV buyers, making the transition to electric vehicles more accessible. This is particularly beneficial for those who might otherwise be deterred by the higher initial costs compared to traditional gasoline-powered cars. Secondly, the incentives stimulate the market by increasing the demand for EVs, which in turn encourages manufacturers to produce more electric vehicles and potentially lower their prices due to increased production volumes.

In summary, tax credits and subsidies are essential components of government strategies to make electric vehicles more affordable and widely adopted. These incentives not only benefit individual consumers by reducing the cost of purchasing EVs but also contribute to a more sustainable and environmentally friendly transportation ecosystem. As the cost of electric vehicles continues to fall, driven in part by these government initiatives, the prospect of a greener and more cost-effective future for personal transportation becomes increasingly tangible.

Strategies to Lower EV Costs: Tips for Affordable Electric Vehicles

You may want to see also

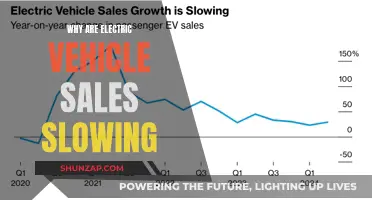

Market Competition: Increased competition drives down prices and encourages innovation

The electric vehicle (EV) market is experiencing a significant shift as more players enter the arena, leading to increased competition. This competitive environment is driving down prices and fostering innovation, which are crucial factors in making electric vehicles more accessible and affordable for the masses.

One of the primary effects of market competition is the pressure on companies to reduce costs. With numerous manufacturers vying for market share, each is striving to offer the best value to consumers. This often translates to lower prices for EV buyers. As the market becomes more saturated, the cost of production and development decreases due to economies of scale. Larger production volumes allow for reduced per-unit costs, making electric vehicles more economically viable. For instance, the average price of electric cars has been steadily decreasing over the years, making them more competitive against traditional gasoline vehicles.

Innovation is another beneficiary of increased competition. When multiple companies compete, they invest in research and development to differentiate their products and gain a competitive edge. This results in rapid advancements in technology, design, and performance. For electric vehicles, this could mean improved battery efficiency, faster charging times, and enhanced driving range. For example, the introduction of new battery chemistries and designs has led to more powerful and longer-lasting batteries, addressing a critical consumer concern.

Moreover, competition encourages companies to focus on customer satisfaction and experience. With a diverse range of options available, consumers have more choices and can demand better quality and features. This shift in consumer behavior further drives manufacturers to enhance their products and services, ensuring they remain competitive. As a result, the market becomes more dynamic and responsive to consumer needs.

In summary, the growing competition in the electric vehicle sector is a powerful force for change. It not only makes EVs more affordable but also propels innovation and improves the overall customer experience. As the market continues to evolve, consumers can expect even more competitive pricing, advanced technologies, and a wider variety of electric vehicles to choose from. This competitive landscape is essential for the long-term success and widespread adoption of electric mobility.

Mastering Short Electrical Wiring: Extending Vehicle Connections Efficiently

You may want to see also

Frequently asked questions

Yes, the cost of electric vehicles (EVs) has been steadily decreasing over the years, making them more accessible to a wider range of buyers. This trend is primarily due to technological advancements, increased production volumes, and government incentives promoting the adoption of electric mobility.

Several factors are driving down the cost of electric vehicles. Firstly, battery technology has improved significantly, allowing for higher energy density and lower production costs. Secondly, economies of scale come into play as more EVs are manufactured, reducing per-unit costs. Additionally, government subsidies and tax incentives for EV buyers have made them more affordable.

AA: Industry experts predict that the cost of electric vehicles will continue to decline, especially as technology matures and production processes become more efficient. With ongoing research and development, it is likely that battery prices will drop further, and other components will become more cost-effective, making EVs even more competitive in the market.

Absolutely! Several automotive manufacturers now offer affordable electric vehicle options. For instance, models like the Nissan Leaf, Chevrolet Bolt, and Hyundai Ioniq Electric provide excellent value for money, often starting from below $30,000. These vehicles offer a balance between performance, range, and price, making them attractive choices for cost-conscious consumers.

Electric vehicles are becoming increasingly cost-competitive with their internal combustion engine counterparts. While the initial purchase price of EVs might be higher, they offer significant long-term savings due to lower fuel and maintenance costs. Additionally, as electricity prices continue to fall, the running costs of EVs become even more attractive compared to traditional gasoline or diesel cars.