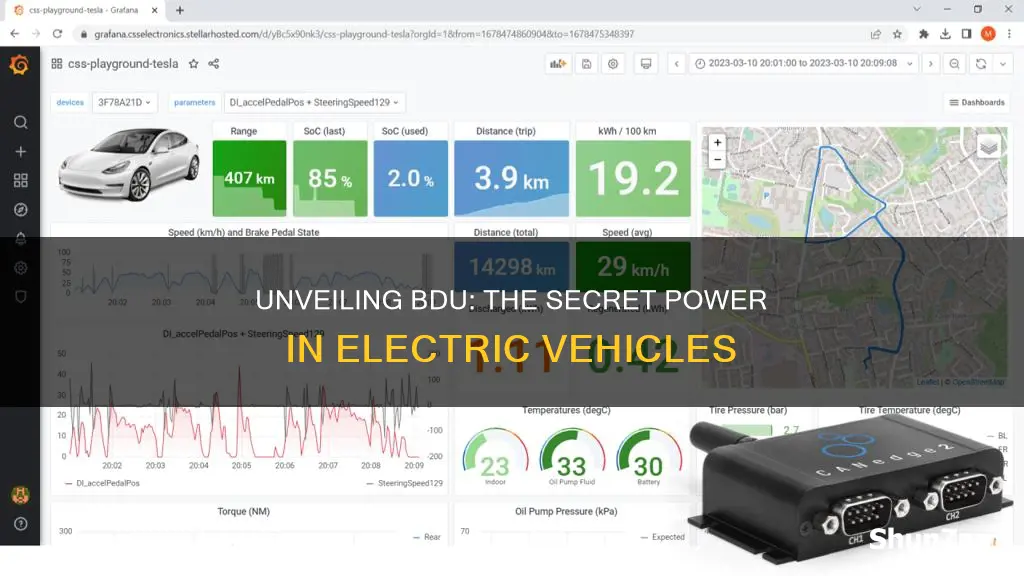

BDU, or Battery Data Unit, is a crucial component in electric vehicles (EVs) that plays a vital role in monitoring and managing the battery's performance and health. It is an electronic device that collects and analyzes data related to the battery's state of charge, temperature, voltage, and other critical parameters. By providing real-time insights, BDU enables efficient battery management, optimizing charging and discharging cycles, and ensuring the longevity and safety of the EV's battery system. This technology is essential for enhancing the overall efficiency and reliability of electric vehicles.

| Characteristics | Values |

|---|---|

| Definition | BDU stands for Battery Data Unit, a term used in the context of electric vehicles (EVs) to describe a unit of measurement for battery performance and efficiency. |

| Purpose | It provides a standardized way to communicate and compare battery-related data across different EV models and manufacturers. |

| Measurement | BDU is typically measured in Wh (watt-hours) or kWh (kilowatt-hours), representing the energy capacity of the battery. |

| Performance Indicator | It helps consumers understand the range an EV can achieve on a single charge, which is crucial for potential buyers. |

| Efficiency | BDU values can indicate the efficiency of the battery, showing how much energy is converted into useful power during driving. |

| Charging Time | Higher BDU values often correlate with faster charging times, as larger batteries can store more energy. |

| Safety | BDU specifications are essential for ensuring the safety of EV batteries, as they provide insights into the battery's health and potential risks. |

| Market Standardization | Many EV manufacturers use BDU as a standard term to provide consistent information to customers, making it easier to compare models. |

| Regulatory Compliance | BDU values are often used to meet regulatory requirements and standards for EV performance and emissions. |

| Research and Development | Researchers and engineers use BDU data to optimize battery technology, improve performance, and develop new EV designs. |

What You'll Learn

- Battery Design: BDU refers to battery design units, focusing on optimizing energy storage

- Charging Efficiency: BDU can also mean battery charging units, enhancing charging speed and efficiency

- Range Extenders: Battery-driven units (BDU) may include range extenders for extended vehicle range

- Thermal Management: BDU can relate to thermal management systems, controlling battery temperature for performance

- Safety Mechanisms: Battery-driven units often incorporate safety features to protect against overheating and short circuits

Battery Design: BDU refers to battery design units, focusing on optimizing energy storage

BDU, or Battery Design Unit, is a critical concept in the field of electric vehicle (EV) technology, specifically in the realm of battery design and optimization. It refers to the fundamental building blocks and design principles that engineers and scientists employ to enhance the energy storage capabilities of batteries used in EVs. The primary goal of BDU is to maximize the energy density, efficiency, and overall performance of batteries, ensuring that electric vehicles can travel longer distances on a single charge.

In the context of battery design, BDU involves a meticulous process of selecting and arranging various components to create a high-performance energy storage system. This includes choosing the right type of battery chemistry, such as lithium-ion, lead-acid, or nickel-metal hydride, each with its own advantages and limitations. For instance, lithium-ion batteries offer high energy density and efficiency but may have safety concerns, while lead-acid batteries are more affordable but less energy-dense. BDU experts must carefully consider these factors to tailor the battery design to the specific requirements of the EV.

One key aspect of BDU is the arrangement of battery cells. This involves stacking or arranging individual cells in a way that optimizes energy output and manages heat dissipation effectively. The design must consider the number of cells, their orientation, and the interconnection methods to ensure efficient power delivery and longevity. Advanced BDU techniques might include modular battery designs, where multiple cells are combined in a standardized manner, allowing for easy replacement and customization.

Additionally, BDU focuses on improving the overall efficiency of the battery system. This includes minimizing energy losses during charging and discharging cycles, optimizing the use of available space within the EV, and implementing smart thermal management systems. By reducing internal resistance and improving charge/discharge rates, BDU can enhance the battery's power density, allowing for faster charging and improved performance during acceleration and high-demand driving conditions.

In summary, BDU is a comprehensive approach to battery design, aiming to create high-performance, efficient, and reliable energy storage systems for electric vehicles. It involves careful selection of battery chemistry, strategic cell arrangement, and innovative design solutions to meet the ever-growing demands of the automotive industry. As technology advances, BDU will continue to play a pivotal role in pushing the boundaries of EV battery performance and driving the widespread adoption of electric mobility.

Electric Vehicle Resale Value: Strategies for Accurate Forecasting

You may want to see also

Charging Efficiency: BDU can also mean battery charging units, enhancing charging speed and efficiency

BDU, in the context of electric vehicles, can indeed stand for Battery Charging Units, which play a crucial role in optimizing the charging process and improving overall charging efficiency. These units are designed to enhance the speed and effectiveness of charging electric vehicle batteries, ensuring a more convenient and time-efficient experience for drivers.

The primary function of BDU (Battery Charging Units) is to provide a controlled and efficient charging environment. When an electric vehicle is connected to a charging station, the BDU system manages the power flow, ensuring that the battery is charged at the optimal rate. This is particularly important as overcharging can lead to reduced battery life and potential safety hazards. By regulating the charging process, BDUs help maintain the health and longevity of the battery pack.

One of the key advantages of BDU is its ability to optimize charging speed. Traditional charging methods often result in slower charging times, which can be inconvenient for vehicle owners. BDU systems employ advanced algorithms and power management techniques to maximize the charging rate while ensuring the battery's safety. This technology can significantly reduce the time required to charge an electric vehicle, making it more practical for daily use.

In addition to speed, BDU also focuses on improving charging efficiency. Charging efficiency refers to the effectiveness of the charging process in converting electrical energy into stored battery power. BDUs achieve higher efficiency by minimizing energy losses during charging. This is crucial as it directly impacts the overall range and performance of the electric vehicle. With improved efficiency, drivers can expect a more reliable and consistent driving experience.

Furthermore, BDU systems can adapt to different charging scenarios and vehicle models. They can communicate with the vehicle's onboard systems to understand the battery's status and adjust charging parameters accordingly. This adaptability ensures that the charging process is tailored to the specific needs of the electric vehicle, further enhancing charging efficiency and overall user satisfaction.

Maximize Your EV Tax Credit: A Step-by-Step Guide to Reporting

You may want to see also

Range Extenders: Battery-driven units (BDU) may include range extenders for extended vehicle range

Battery-driven units (BDUs) are an essential component in the evolution of electric vehicles (EVs), offering a solution to the range anxiety often associated with these vehicles. These units are designed to power the vehicle's electric motor and can be integrated with various systems to enhance the overall performance and efficiency of EVs. One of the key features of BDUs is their ability to incorporate range extenders, which are particularly useful for extending the vehicle's range beyond what a standard battery pack can provide.

Range extenders are small, battery-driven generators that can be used to recharge the main battery pack while the vehicle is in operation. This technology is especially beneficial for long-distance travel, as it allows EVs to cover greater distances without the need for frequent charging stops. The range extender is typically a compact, lightweight unit that can be mounted in various positions within the vehicle, ensuring minimal impact on the overall design and aesthetics.

The operation of a range extender is straightforward. It utilizes a small internal combustion engine (ICE) or a fuel cell to generate electricity, which is then used to recharge the main battery pack. This process ensures that the vehicle's battery remains topped up, providing the necessary power to the electric motor. During this operation, the range extender can be designed to run on either gasoline, diesel, or alternative fuels, making it a versatile solution for different EV models.

Incorporating range extenders into BDUs offers several advantages. Firstly, it significantly increases the vehicle's range, making EVs more practical for daily use and long-distance travel. This feature can attract a broader consumer base, as it addresses the primary concern of limited range in early EVs. Secondly, the use of a range extender allows for more efficient energy management, as the vehicle can optimize power usage between the main battery and the extender, reducing overall fuel consumption.

Designing and implementing range extenders requires careful consideration of various factors. Engineers must ensure that the extender's size and weight do not compromise the vehicle's performance and handling. Additionally, the integration of the extender with the main battery system needs to be seamless to provide a smooth and efficient power supply. Despite the challenges, range extenders have the potential to revolutionize the EV market, making electric vehicles more appealing to a wider audience.

Unlocking EV Savings: A Guide to Claiming Your Subsidy

You may want to see also

Thermal Management: BDU can relate to thermal management systems, controlling battery temperature for performance

The BDU (Battery Data Unit) in the context of electric vehicles (EVs) is a crucial component that plays a significant role in optimizing the vehicle's performance and efficiency, particularly in thermal management. Thermal management is a critical aspect of EV design, as it directly impacts the battery's performance, longevity, and overall safety. The BDU is an integral part of this system, providing real-time data and insights to ensure the battery operates within optimal temperature ranges.

In an electric vehicle, the battery pack generates heat during operation, and maintaining the right temperature is essential for several reasons. Firstly, it ensures the battery operates at its peak efficiency. Lithium-ion batteries, commonly used in EVs, have an optimal temperature range where they perform best. If the temperature is too low, the chemical reactions within the battery slow down, reducing power output. Conversely, if the temperature is too high, it can lead to performance degradation and even safety concerns, such as thermal runaway.

BDU is designed to monitor and control the temperature of the battery pack. It does this by collecting and analyzing data from various sensors placed throughout the battery system. These sensors measure temperature, current, voltage, and other critical parameters. The BDU then processes this data to provide insights into the battery's health and performance. For instance, it can detect when the battery temperature is rising too quickly and take appropriate action to prevent overheating.

One of the key functions of the BDU in thermal management is to activate cooling systems when necessary. This can include liquid cooling, where a coolant circulates through the battery pack to absorb heat, or air cooling, which uses fans to dissipate heat. By precisely controlling the cooling process, the BDU ensures that the battery temperature remains within the desired range, even during high-demand driving conditions. This not only improves the vehicle's performance but also extends the battery's lifespan by reducing thermal stress.

Additionally, the BDU can contribute to energy efficiency. By optimizing the battery's temperature, it can help reduce energy losses associated with temperature variations. This is particularly important in regenerative braking systems, where the kinetic energy of the vehicle is converted back into electrical energy. Efficient thermal management ensures that this energy is stored effectively, improving the overall efficiency of the EV. In summary, the BDU's role in thermal management is vital for maintaining the performance, safety, and efficiency of electric vehicle batteries.

Smith Electric Vehicles: A Journey from Success to Struggles

You may want to see also

Safety Mechanisms: Battery-driven units often incorporate safety features to protect against overheating and short circuits

Battery-driven units, particularly those in electric vehicles, are designed with advanced safety mechanisms to ensure the well-being of both the vehicle and its occupants. One of the primary concerns in these systems is preventing overheating, which can lead to performance degradation and, in extreme cases, fire hazards. To mitigate this risk, manufacturers employ various strategies. For instance, many BDU (Battery-Driven Unit) systems incorporate temperature sensors that constantly monitor the battery's thermal status. These sensors detect any abnormal rise in temperature and trigger a response mechanism, such as reducing the charging rate or activating cooling fans, to maintain optimal operating conditions.

In addition to temperature control, short circuit protection is another critical aspect of safety. Short circuits can occur due to various reasons, including manufacturing defects, physical damage, or electrical faults. To address this, BDU systems often feature circuit breakers or fuses that can detect and interrupt the flow of electricity in the event of a short circuit. This rapid response helps prevent excessive current from causing damage to the battery or the vehicle's electrical system.

Overcurrent protection is another essential safety feature. It involves monitoring the current flowing through the battery and taking action if it exceeds safe limits. This can be achieved through the use of current sensors and control algorithms that adjust the charging or discharging rates accordingly. By managing the current, the system can prevent damage to the battery cells and ensure a longer lifespan.

Furthermore, some BDU systems are equipped with advanced battery management systems (BMS) that provide comprehensive protection. The BMS can monitor and control various parameters, including voltage, current, and temperature, to ensure the battery operates within safe boundaries. It can also optimize charging and discharging processes, improving overall efficiency and safety.

In summary, the safety mechanisms in battery-driven units are designed to safeguard against overheating and short circuits, which are potential risks associated with electric vehicle batteries. Through the use of sensors, control systems, and protective devices, these mechanisms ensure the safe operation of the vehicle, enhance the longevity of the battery, and contribute to the overall reliability of electric transportation.

Boosting EV Efficiency: Tips for Optimal Battery Performance

You may want to see also

Frequently asked questions

BDU stands for Battery Data Unit, which is a crucial component in electric vehicles (EVs) that manages and stores data related to the vehicle's battery performance and health. It acts as a central hub for monitoring and optimizing the battery's performance, ensuring efficient energy management and extending the vehicle's range.

The BDU plays a vital role in enhancing the efficiency and reliability of electric vehicles. It collects and analyzes data such as battery voltage, current, temperature, and state of charge. By processing this information, the BDU can provide real-time insights to the vehicle's control system, allowing for optimized power distribution, improved performance, and efficient energy usage.

Absolutely! BDU is essential for monitoring and maintaining the health of the vehicle's battery pack. It tracks various parameters like battery capacity, cycle life, and temperature distribution. By continuously monitoring these factors, the BDU can detect early signs of degradation, optimize charging patterns, and provide alerts to the driver or maintenance team, ensuring the longevity and reliability of the electric vehicle's battery.