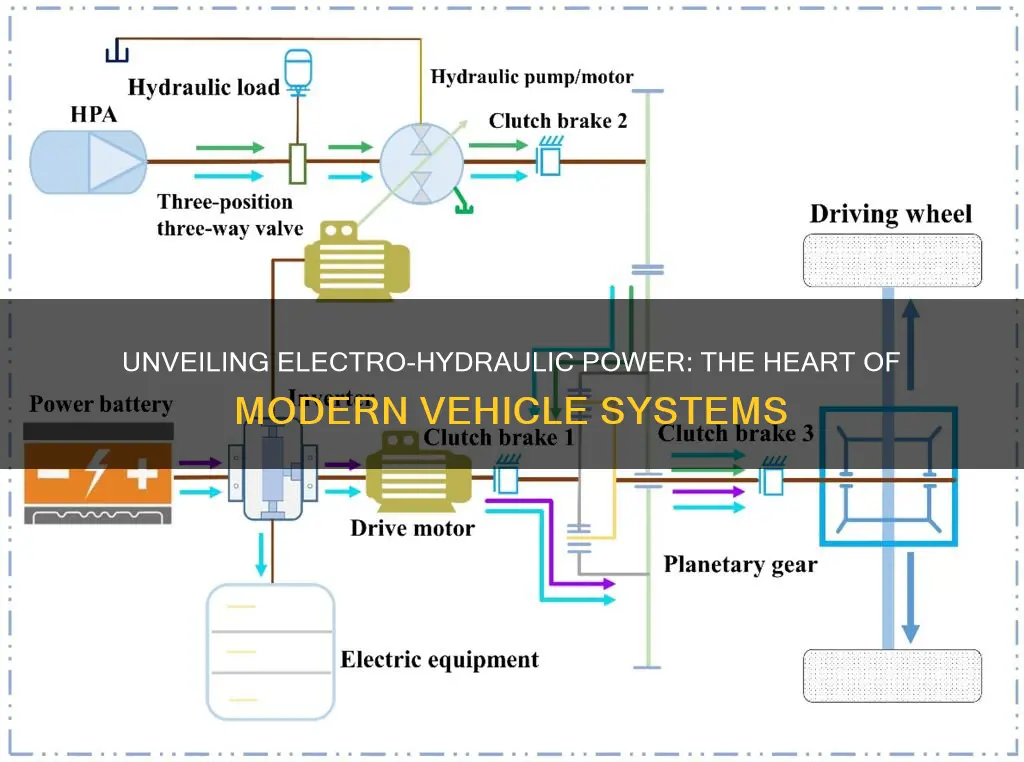

The electro-hydraulic system in vehicles is a sophisticated technology that integrates electrical and hydraulic components to enhance vehicle performance and control. This system utilizes electrical signals to activate and control hydraulic fluid, which then operates various vehicle functions, such as braking, steering, and suspension. By combining the precision of electrical systems with the power and force of hydraulics, this technology enables precise control over critical vehicle components, ensuring optimal performance, safety, and efficiency. Understanding the electro-hydraulic functioning of a vehicle system is crucial for mechanics and vehicle owners to maintain and optimize the vehicle's performance and longevity.

What You'll Learn

- Hydraulic Power: How fluid pressure is used to generate force for vehicle systems

- Electro-Mechanical Control: Electronic components control hydraulic valves and actuators

- Brake Systems: Hydraulic brakes convert kinetic energy into heat, slowing the vehicle

- Suspension and Steering: Hydraulic cylinders adjust ride height and steering response

- Engine Control: Electro-hydraulic systems optimize engine performance and fuel efficiency

Hydraulic Power: How fluid pressure is used to generate force for vehicle systems

Hydraulic power is a fundamental concept in modern vehicle systems, utilizing the principles of fluid pressure to generate force and control various mechanical functions. This system is a sophisticated network of components that work in harmony to provide precise and powerful operations, especially in heavy-duty vehicles and machinery. The core idea is to transmit power through incompressible fluids, typically oil, which can be easily directed and controlled under pressure.

In a vehicle's hydraulic system, a pump is the primary component that creates the necessary fluid pressure. This pump is often driven by the vehicle's engine, ensuring a constant and reliable power source. When activated, the pump forces the hydraulic fluid through a series of carefully designed passages and channels, creating pressure that can be harnessed for various tasks. The beauty of this system lies in its ability to amplify force; even a relatively small input can result in a substantial output due to the incompressibility of the fluid and the principles of Pascal's law.

One of the most common applications of hydraulic power in vehicles is in the braking system. When a driver applies pressure to the brake pedal, it activates a master cylinder, which then forces hydraulic fluid through brake lines to the individual brakes on each wheel. This pressure is transmitted through the fluid, allowing for precise control and modulation of braking force, ensuring safe and responsive stopping power. The hydraulic system's ability to distribute force evenly and efficiently makes it ideal for such critical safety mechanisms.

Hydraulic systems are also prevalent in vehicle suspension and steering mechanisms. In suspension, hydraulic cylinders are used to absorb shocks and provide a smooth ride. When a wheel encounters an obstacle, the hydraulic fluid's pressure is adjusted to extend or retract the cylinder, offering a dampening effect and maintaining stability. Similarly, power steering systems utilize hydraulic pressure to assist in steering, making it easier for drivers to maneuver the vehicle, especially at low speeds or when parking.

The electro-hydraulic functioning of a vehicle system involves the integration of electrical components to control and regulate the hydraulic processes. Sensors and actuators are employed to monitor fluid pressure, temperature, and flow rates, ensuring optimal performance and safety. This electronic control allows for precise adjustments, enabling the system to adapt to varying loads and driving conditions. Modern vehicles often feature advanced hydraulic systems that are fully integrated with the vehicle's electronic control unit (ECU), allowing for dynamic adjustments and improved overall efficiency.

Unraveling the Mystery: What's PHEV Mean for Electric Vehicles?

You may want to see also

Electro-Mechanical Control: Electronic components control hydraulic valves and actuators

Electro-hydraulic systems in vehicles are a sophisticated integration of electronic and hydraulic technologies, enabling precise control and enhanced performance. At the heart of this system are electronic components that play a pivotal role in managing the hydraulic valves and actuators, which are responsible for various vehicle functions.

The electronic control unit (ECU) is the brain of the electro-hydraulic system. It receives input signals from various sensors, such as speed, temperature, and pressure sensors, and processes this data to make decisions. These decisions are then translated into commands for the hydraulic valves and actuators. For instance, when the driver operates the accelerator pedal, the ECU interprets the input and sends a signal to the hydraulic actuator, which in turn activates the corresponding hydraulic valve. This valve regulates the flow of hydraulic fluid, allowing for precise control of the vehicle's engine or other mechanical systems.

Electronic components, such as microcontrollers and digital signal processors, are used to control the timing and magnitude of the hydraulic valve's movement. These components ensure that the valves open and close at the right time and with the required force, optimizing the system's performance. The use of electronic controls also enables the system to adapt to changing conditions, such as varying loads or environmental factors, by adjusting the hydraulic pressure accordingly.

Hydraulic valves are a critical component in this setup. They are designed to direct the flow of hydraulic fluid to different actuators, such as cylinders or motors, based on the ECU's commands. These valves can be solenoid-operated, meaning an electric current activates a solenoid, which then moves a valve pin to open or close the valve. This mechanism allows for rapid and precise control of fluid flow, ensuring the vehicle's systems respond efficiently.

The actuators, such as hydraulic cylinders or motors, are responsible for converting the hydraulic energy into mechanical motion. When the hydraulic valves direct the fluid to the actuators, they extend or retract, providing the necessary force and movement. This mechanical action can be utilized for various purposes, including braking, steering, suspension control, and gear shifting in transmissions. The electronic control system ensures that the actuators receive the appropriate amount of hydraulic pressure to perform their tasks accurately.

In summary, electro-hydraulic systems in vehicles rely on electronic components to manage the complex interplay between hydraulic valves and actuators. This control system enables precise and responsive vehicle operations, contributing to improved performance, efficiency, and overall driving experience.

Green Incentives: Why Go Electric?

You may want to see also

Brake Systems: Hydraulic brakes convert kinetic energy into heat, slowing the vehicle

The hydraulic brake system is a critical component of a vehicle's safety mechanism, responsible for slowing down and stopping the vehicle by converting kinetic energy into heat. When you apply the brakes, a series of intricate processes are set in motion, all designed to ensure a safe and controlled deceleration.

At its core, the hydraulic brake system utilizes a network of tubes and cylinders filled with brake fluid, which acts as the medium for transmitting force. When the brake pedal is depressed, it activates the master cylinder, creating a vacuum that forces the brake fluid through the lines to the individual wheel cylinders or calipers. This process is similar to how a simple hydraulic lift works, where applying pressure at one point (the master cylinder) results in an equal and opposite reaction at another (the wheel cylinders).

The wheel cylinders or calipers then apply pressure to the brake rotors or discs, which are attached to the wheels. These rotors are made of a sturdy material like cast iron or composite and are designed to rotate with the wheels. When the brake pads or shoes make contact with the rotors, friction is generated, causing the rotors to slow down and eventually stop the wheel's rotation, thus slowing down the vehicle.

The beauty of this system lies in its ability to distribute the force evenly across all four wheels (or more, depending on the vehicle type). This ensures that the vehicle decelerates uniformly, providing better control and stability. As the brakes are applied, the kinetic energy of the moving vehicle is transformed into heat energy, which is dissipated through the rotors and pads, eventually cooling down as it spreads into the surrounding air.

It's important to note that regular maintenance and inspection of the hydraulic brake system are crucial to ensure optimal performance and safety. Over time, brake fluid can absorb moisture, leading to reduced braking efficiency. Additionally, wear and tear on brake pads, rotors, and other components can affect the overall braking power. Therefore, drivers should be vigilant about checking brake fluid levels and replacing worn-out parts to maintain the integrity of the hydraulic brake system.

Unveiling the Power of All-Electric Vehicles: A Comprehensive Guide

You may want to see also

Suspension and Steering: Hydraulic cylinders adjust ride height and steering response

The electro-hydraulic system in a vehicle is a sophisticated mechanism that plays a crucial role in enhancing the driving experience and overall vehicle performance. One of its key functions is the adjustment of ride height and steering response, which is facilitated by hydraulic cylinders. These cylinders are integral components of the suspension and steering systems, providing precise control over the vehicle's ride comfort and handling.

In the suspension system, hydraulic cylinders are strategically placed to control the movement of the vehicle's wheels relative to the chassis. When the vehicle encounters bumps or uneven road surfaces, the suspension system absorbs the impact, ensuring a smoother ride. Hydraulic cylinders are used to dampen this movement and provide a more comfortable driving experience. The cylinders work by extending and retracting, allowing the suspension to compress and rebound, thus maintaining optimal contact between the tires and the road. This adjustment of ride height is crucial for maintaining stability, especially during high-speed driving or when navigating sharp turns.

The steering system also benefits from the electro-hydraulic functioning. Hydraulic cylinders are employed in power steering units to assist the driver in turning the steering wheel. When the driver applies force to the steering wheel, the hydraulic cylinder responds by providing the necessary hydraulic pressure to turn the steering gear, making the steering effort less strenuous. This system ensures that the steering response is precise and proportional to the driver's input, allowing for better control and maneuverability.

The electro-hydraulic system's ability to adjust ride height and steering response is achieved through the use of electronic controls and sensors. These sensors monitor the vehicle's speed, acceleration, and steering angle, providing real-time data to the electronic control unit (ECU). The ECU then calculates the appropriate hydraulic pressure required to adjust the suspension and steering accordingly. This electronic control allows for dynamic adjustments, ensuring that the vehicle's suspension and steering are optimized for various driving conditions.

In summary, the electro-hydraulic functioning of a vehicle system, particularly in the context of suspension and steering, is a sophisticated process that enhances driving comfort and control. Hydraulic cylinders, in conjunction with electronic controls, enable precise adjustments to ride height and steering response, contributing to a more stable and responsive driving experience. This technology is a testament to the continuous innovation in automotive engineering, aiming to provide drivers with a safer and more enjoyable journey.

Upstart VinFast: Redefining the Electric Vehicle Industry

You may want to see also

Engine Control: Electro-hydraulic systems optimize engine performance and fuel efficiency

Electro-hydraulic systems play a crucial role in modern vehicle engineering, particularly in engine control and management. These systems utilize the combination of electrical and hydraulic technologies to precisely regulate various engine functions, resulting in improved performance, fuel efficiency, and overall vehicle dynamics. By integrating these two powerful technologies, engineers can achieve a level of control and responsiveness that was once unimaginable.

At the heart of an electro-hydraulic engine control system is the ability to precisely manage the flow of hydraulic fluid. This fluid is used to actuate various engine components, such as valves and pistons, with remarkable accuracy. The electrical component comes into play by controlling the pressure and direction of the hydraulic fluid through the use of pumps, actuators, and valves. This level of control allows for fine-tuning of engine parameters, ensuring optimal performance under various driving conditions.

One of the key advantages of electro-hydraulic systems is their ability to optimize fuel efficiency. By precisely controlling the engine's intake and exhaust processes, these systems can minimize fuel consumption without compromising power output. For instance, they can adjust the fuel injection timing, optimize air-fuel mixture, and manage the engine's idle speed, all of which contribute to better fuel economy. This level of control is especially beneficial for vehicles, as it reduces environmental impact and operating costs.

In terms of engine performance, electro-hydraulic systems offer enhanced responsiveness and power delivery. The electrical control unit can rapidly adjust the hydraulic pressure to actuate engine components, resulting in faster engine response times. This is particularly advantageous during acceleration, as the system can quickly deliver the required power to the wheels, improving overall vehicle performance. Additionally, the precision of these systems allows for better control over engine speed and torque, ensuring a smooth and responsive driving experience.

Furthermore, electro-hydraulic technology enables advanced features such as variable valve timing and lift. By adjusting the hydraulic pressure, the system can vary the valve opening and closing times, optimizing the engine's performance across different operating ranges. This technology is especially beneficial for engines used in high-performance vehicles, where precise control over combustion and power output is essential. The result is a more efficient and powerful engine, capable of delivering exceptional performance while maintaining fuel efficiency.

In summary, electro-hydraulic systems in vehicle engines provide a sophisticated means of controlling and optimizing engine performance. By integrating electrical and hydraulic technologies, these systems offer precise management of engine functions, leading to improved fuel efficiency, enhanced responsiveness, and overall better vehicle dynamics. As automotive engineering continues to evolve, the role of electro-hydraulic systems will undoubtedly become even more prominent, shaping the future of efficient and powerful transportation.

Electric Vehicle Lease: Is It Worth It?

You may want to see also

Frequently asked questions

The electro-hydraulic system is an advanced technology used in modern vehicles, particularly in heavy-duty applications like trucks, buses, and construction machinery. It combines electrical and hydraulic components to control and operate various vehicle functions, such as braking, steering, and suspension. This system allows for precise and efficient control, enabling improved performance, safety, and comfort.

This system operates by using an electric motor to power a hydraulic pump, which generates pressurized hydraulic fluid. This fluid is then directed to different actuators or cylinders throughout the vehicle. The electric control unit (ECU) plays a crucial role in receiving input from sensors and sending signals to the motor, ensuring the system responds accurately to driver commands.

Electro-hydraulics offer several benefits. They provide faster response times compared to traditional hydraulic systems, ensuring quicker and more precise control. The system can also offer improved safety through advanced braking and steering assistance. Additionally, electro-hydraulics contribute to better fuel efficiency and reduced maintenance requirements due to the absence of leaks and the use of sealed systems.

The Electric Control Unit (ECU) is the brain of the electro-hydraulic system. It receives input from various sensors, such as speed, pressure, and temperature sensors, to monitor the vehicle's performance. The ECU then processes this data and sends the appropriate signals to the electric motor, ensuring the hydraulic system operates as desired. It also has the capability to adjust parameters in real-time, optimizing the system's performance and safety.