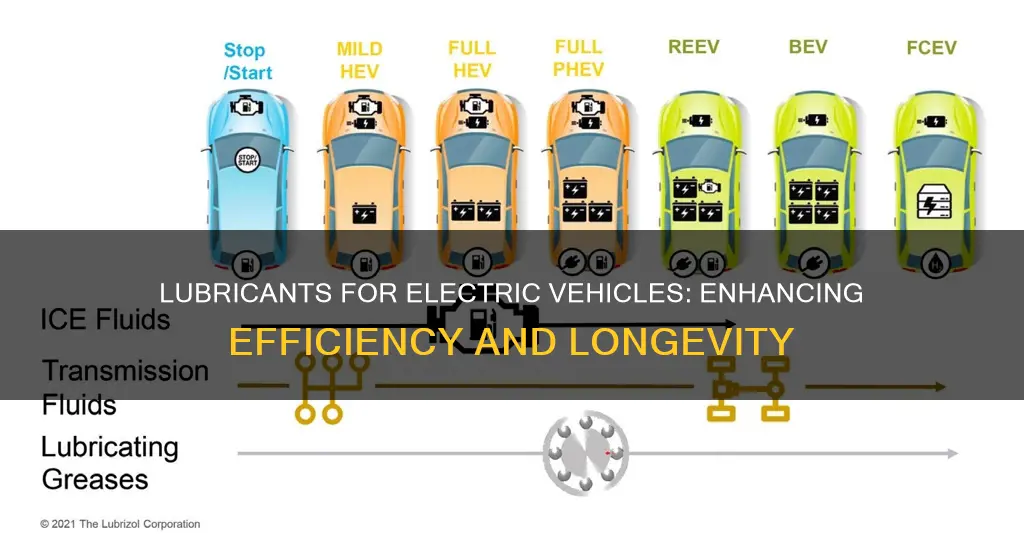

When it comes to electric vehicles, the choice of lubricant is crucial for ensuring optimal performance and longevity. Unlike traditional internal combustion engines, electric vehicles rely on sophisticated systems that require specific lubricants to function efficiently. The primary concern is to minimize friction and wear in the motor, transmission, and other mechanical components. Therefore, the lubricant must possess unique properties to address the unique challenges of electric vehicle mechanics. This includes the ability to withstand high temperatures, provide excellent anti-wear protection, and maintain stability in varying operating conditions. The right lubricant can significantly contribute to the overall efficiency and reliability of electric vehicles, making it a critical aspect of their maintenance.

What You'll Learn

- Lubricant Types: Synthetic oils, bio-based lubricants, and polytetrafluoroethylene (PTFE) greases are common choices

- EV Motor Lubrication: Focus on reducing friction in electric motors, ensuring efficient operation

- Gearbox Maintenance: Lubricants for CVTs and DCTs are crucial for smooth gear shifting

- Cooling Systems: Lubricants help dissipate heat, maintaining optimal temperatures in EV cooling systems

- Battery Lubrication: Special lubricants protect battery components, enhancing longevity and performance

Lubricant Types: Synthetic oils, bio-based lubricants, and polytetrafluoroethylene (PTFE) greases are common choices

When it comes to lubricants for electric vehicles (EVs), the choice of lubricant is crucial to ensure optimal performance and longevity of the vehicle's components. Here, we explore the various types of lubricants commonly used in EVs, focusing on synthetic oils, bio-based lubricants, and polytetrafluoroethylene (PTFE) greases.

Synthetic Oils: Synthetic oils are a popular choice for EVs due to their exceptional performance characteristics. These oils are engineered to provide superior lubrication, even in extreme temperatures. They offer excellent thermal stability, ensuring that the lubricant remains effective under the high-heat conditions often encountered in electric motors. Synthetic oils also have a low viscosity, allowing for smooth operation and reduced friction. This is particularly important in EVs, where efficient energy transfer is essential. Additionally, synthetic oils are known for their resistance to oxidation and breakdown, ensuring that the lubricant remains effective over extended periods, which is crucial for the long-term reliability of the vehicle.

Bio-Based Lubricants: As the name suggests, bio-based lubricants are derived from renewable biological sources, such as plant oils and animal fats. These lubricants offer several advantages for EVs. Firstly, they are biodegradable, making them environmentally friendly and reducing the potential environmental impact of vehicle maintenance. Bio-based lubricants also provide good lubrication properties, including low viscosity and excellent thermal stability. They are particularly useful in EV applications where traditional mineral oils might not be suitable due to their potential environmental concerns. The use of bio-based lubricants can contribute to a more sustainable and eco-conscious approach to EV maintenance.

Polytetrafluoroethylene (PTFE) Greases: PTFE greases, also known as Teflon greases, are a specialized type of lubricant commonly used in high-performance applications. In the context of EVs, these greases are often employed in specific areas where traditional lubricants might not provide the required performance. PTFE greases offer exceptional resistance to high temperatures and maintain their lubricating properties even under extreme conditions. This makes them ideal for use in EV components like gears, bearings, and joints that experience significant stress and heat. The non-stick nature of PTFE ensures that components remain well-lubricated without the risk of excessive wear or tear.

The choice of lubricant for EVs depends on various factors, including the specific vehicle design, operating conditions, and environmental considerations. Synthetic oils provide excellent thermal stability and low viscosity, making them versatile for different EV components. Bio-based lubricants offer an eco-friendly alternative with good lubrication properties, while PTFE greases excel in high-performance, temperature-sensitive applications. Understanding these lubricant types and their unique characteristics allows EV manufacturers and maintenance professionals to make informed decisions, ensuring the optimal performance and longevity of electric vehicles.

Unlocking EV Potential: Overcoming Range Anxiety and Charging Infrastructure Challenges

You may want to see also

EV Motor Lubrication: Focus on reducing friction in electric motors, ensuring efficient operation

Electric vehicles (EVs) rely on efficient and reliable electric motors for their smooth operation, and proper lubrication plays a crucial role in maintaining these motors' performance and longevity. The primary goal of EV motor lubrication is to minimize friction within the motor, which directly impacts its efficiency and overall lifespan. Friction is a natural byproduct of mechanical movement, but in electric motors, it can lead to increased energy consumption, reduced efficiency, and even premature wear and tear.

The lubrication process in electric motors involves using specialized lubricants designed to withstand the unique challenges of these high-performance systems. Unlike traditional internal combustion engines, electric motors operate at much higher speeds and under varying loads, requiring lubricants that can provide consistent protection. The lubricant's primary function is to create a protective film between moving parts, reducing direct contact and, consequently, friction. This film acts as a barrier, preventing metal-to-metal contact and minimizing wear and tear on critical components like bearings, gears, and the rotor.

When selecting a lubricant for EV motors, several key factors come into play. Firstly, the lubricant should have excellent thermal stability to handle the high operating temperatures of electric motors without breaking down. This ensures that the lubricant remains effective over the entire temperature range the motor experiences. Secondly, the lubricant must possess superior anti-wear properties to protect against friction-induced damage. It should also have good anti-corrosion characteristics to prevent the formation of rust and other corrosive substances, which can accelerate wear and reduce motor efficiency.

Synthetic lubricants, such as polyalphaolefin (PAO) and polyol ester (POE) oils, are commonly used in EV motors due to their exceptional performance characteristics. These synthetic oils offer superior thermal stability, low viscosity, and excellent low-temperature performance, making them ideal for the demanding conditions of electric motors. Additionally, they provide excellent protection against wear and corrosion, ensuring the motor's longevity and efficient operation.

In summary, EV motor lubrication is a critical aspect of maintaining the efficiency and reliability of electric vehicles. By using specialized lubricants that reduce friction, protect against wear, and maintain stability under varying temperatures, EV manufacturers can ensure that their motors operate optimally, contributing to the overall success and longevity of the electric vehicle market. Proper lubrication practices are essential to keeping these motors running smoothly and efficiently for years to come.

Unraveling the Mystery: How Voltage Regulators Power Your Car's Electrical Journey

You may want to see also

Gearbox Maintenance: Lubricants for CVTs and DCTs are crucial for smooth gear shifting

The maintenance of an electric vehicle's gearbox is a critical aspect of ensuring optimal performance and longevity. Among the various components that require attention, the transmission plays a pivotal role in delivering smooth gear shifts and efficient power transmission. This is particularly true for Continuously Variable Transmissions (CVTs) and Dual-Clutch Transmissions (DCTs), which are prevalent in modern electric vehicles. These transmission types demand specific lubricants to function optimally and provide a seamless driving experience.

CVTs and DCTs rely on specialized lubricants to facilitate smooth gear shifting and reduce friction between moving parts. The primary function of these lubricants is to minimize wear and tear, ensuring that the transmission operates efficiently over an extended lifespan. For CVTs, a unique challenge arises due to their design, which often includes a belt or chain-driven system. This system requires a lubricant that can effectively reduce friction between the belt and pulley surfaces while also providing adequate protection against wear and tear.

DCTs, on the other hand, utilize two separate gear sets, each with its own clutch and gear mechanism. The lubricant for DCTs must be capable of reducing friction between the clutch plates and providing sufficient cooling to prevent overheating during high-performance driving. The right lubricant ensures that the clutches engage and disengage smoothly, allowing for quick and precise gear changes.

When it comes to choosing the appropriate lubricant, it is essential to consider the manufacturer's recommendations. Original Equipment Manufacturer (OEM) specifications are crucial, as they are designed to meet the specific requirements of the vehicle's transmission. Using the recommended lubricant ensures that the gearbox operates optimally, maintaining the vehicle's performance and reliability.

In summary, gearbox maintenance, especially for CVTs and DCTs, is a critical task for electric vehicle owners. The use of the correct lubricant is vital for achieving smooth gear shifts, reducing wear, and ensuring the overall longevity of the transmission system. By adhering to manufacturer guidelines and staying proactive with maintenance, electric vehicle owners can enjoy a seamless and efficient driving experience.

Apple's Electric Vehicle: Rumors, Speculations, and the Future of Apple Cars

You may want to see also

Cooling Systems: Lubricants help dissipate heat, maintaining optimal temperatures in EV cooling systems

The cooling system is a critical component of any electric vehicle (EV), ensuring that the battery, motor, and other electrical components operate efficiently and safely. Effective cooling is essential to prevent overheating, which can lead to reduced performance, damage to the vehicle, and even safety hazards. Lubricants play a vital role in the cooling system's performance, particularly in dissipating heat and maintaining optimal temperatures.

In EV cooling systems, lubricants are used in various ways. One primary function is to reduce friction between moving parts, which can generate heat. By minimizing friction, lubricants help to ensure that the cooling system operates smoothly and efficiently. This is especially important in the high-speed, high-torque environments of electric motors and batteries.

Cooling system lubricants are designed to withstand the extreme conditions found in EVs. They must be able to handle high temperatures, pressures, and chemical environments. These lubricants are typically synthetic, formulated to provide excellent thermal stability and oxidation resistance. They are engineered to resist breakdown under high temperatures, ensuring that the cooling system continues to function effectively even when the vehicle is operating at peak performance.

The role of lubricants in the cooling system extends beyond friction reduction. They also contribute to the overall efficiency of the cooling process. Effective lubricants help to ensure that heat is efficiently transferred from the components to the cooling fluid (often a specialized coolant). This coolant then carries the heat away from the vehicle, maintaining optimal temperatures. The right lubricant can enhance the heat transfer capabilities of the cooling system, ensuring that the EV's performance remains consistent and reliable.

In summary, lubricants are essential components of EV cooling systems, playing a critical role in heat dissipation and temperature control. They help to ensure that the vehicle's electrical components operate efficiently and safely, contributing to the overall reliability and performance of the electric vehicle. By understanding the specific requirements of EV cooling systems, engineers can select the appropriate lubricants to optimize the vehicle's cooling performance.

Parking Privileges: Unlocking Free EV Parking Benefits

You may want to see also

Battery Lubrication: Special lubricants protect battery components, enhancing longevity and performance

The electric vehicle (EV) market is rapidly growing, and with it, the demand for efficient and long-lasting battery systems. One crucial aspect often overlooked is the role of lubrication in maintaining and optimizing these battery components. Battery lubrication is a specialized process that involves using specific lubricants to ensure the smooth operation and extended lifespan of EV batteries.

In the intricate world of EV batteries, various components work in harmony to store and release energy efficiently. These components include electrodes, separators, and current collectors, all of which require precise lubrication to function optimally. The right lubricant acts as a protective barrier, reducing friction and preventing excessive wear and tear. This is particularly important in the high-performance, high-stress environment of an EV battery.

Special lubricants designed for EV batteries are typically synthetic and engineered to meet the unique demands of these systems. These lubricants are formulated to withstand the extreme temperatures and chemical environments present within the battery. For instance, they must remain stable under high-temperature conditions, which are common during charging and discharging cycles. Additionally, these lubricants should be compatible with the various materials used in the battery, such as lithium-ion, to ensure no adverse reactions or degradation of performance.

The benefits of proper lubrication are significant. Firstly, it minimizes the risk of internal short circuits, which can occur due to the degradation of current collectors or electrodes. Lubricants help maintain the integrity of these components, ensuring they remain in good condition and do not come into contact with each other prematurely. Secondly, lubrication reduces the likelihood of corrosion, which can severely impact battery performance and longevity. By providing a protective layer, lubricants keep the battery's internal surfaces clean and free from corrosive elements.

Furthermore, the use of specialized lubricants can enhance the overall efficiency of the EV battery. With reduced friction, the movement of ions and electrons becomes smoother, leading to improved charge and discharge rates. This results in faster charging times and extended driving ranges for electric vehicles. In summary, battery lubrication is a critical yet often overlooked aspect of EV maintenance. By utilizing the right lubricants, EV manufacturers can ensure the reliability and performance of their battery systems, ultimately contributing to the widespread adoption and success of electric vehicles.

Boosting EV Speed: Tips for Faster, More Efficient Driving

You may want to see also

Frequently asked questions

Electric vehicle motors often use synthetic lubricants specifically designed for high-performance and low-friction applications. These lubricants are typically synthetic oils or greases that provide excellent thermal stability, low viscosity, and anti-wear properties, ensuring efficient operation and longevity of the motor.

The lubrication requirements for electric vehicles can vary depending on the manufacturer's recommendations and driving conditions. Generally, it is advised to change the lubricant (oil or grease) every 50,000 to 100,000 miles or as per the EV manufacturer's guidelines. Regular maintenance ensures optimal performance and prevents excessive wear.

While regular motor oil might work, it is not ideal for electric vehicles. Synthetic lubricants are preferred due to their superior performance in extreme temperatures and reduced friction. Using the recommended synthetic lubricant ensures compatibility with the EV's components and helps maintain efficiency.

The transmission and drivetrain in electric vehicles often require specialized lubricants. These systems may use a combination of synthetic oils and greases to ensure smooth operation and prevent excessive wear. It's crucial to use the correct lubricant type and viscosity as specified by the manufacturer.

Battery systems in electric vehicles typically do not require traditional lubricants. However, some manufacturers might use specialized lubricants for specific components like battery cooling systems. It's essential to consult the EV manufacturer's recommendations for any battery-related lubrication needs.