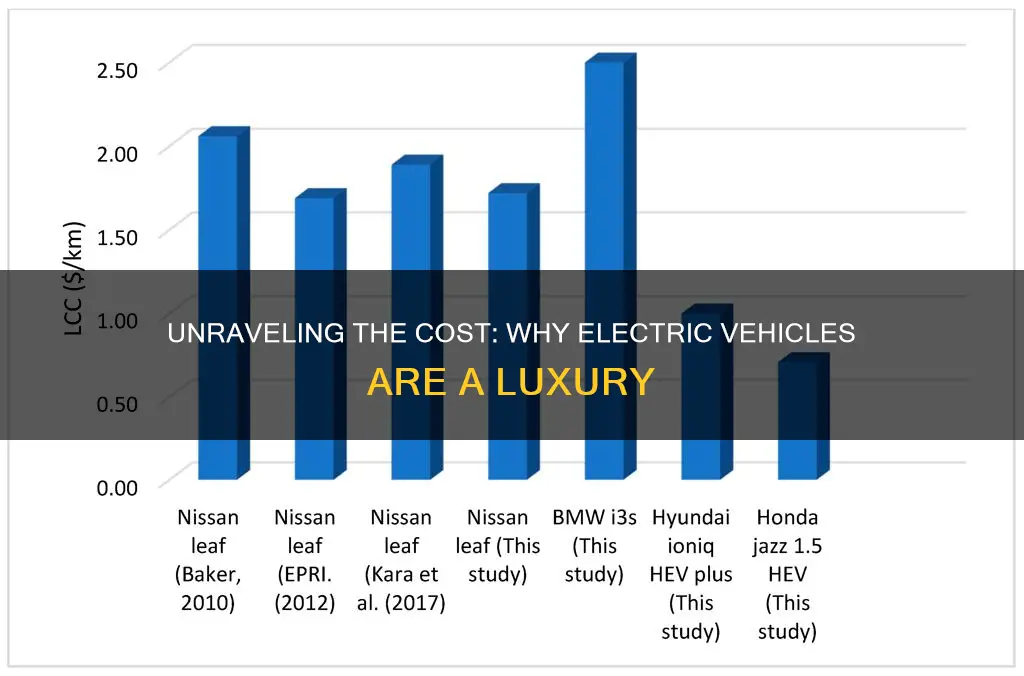

Electric vehicles (EVs) have gained significant popularity in recent years, but their high price tags often raise questions. The cost of EVs can be attributed to several factors, including advanced technology, battery production, and infrastructure. These vehicles utilize cutting-edge components like powerful electric motors, sophisticated battery packs, and advanced driver-assistance systems, which contribute to their higher upfront costs. Additionally, the production of lithium-ion batteries, a critical component in EVs, is energy-intensive and requires specialized materials, further increasing manufacturing expenses. Furthermore, the development of charging infrastructure and the need for extensive research and development to meet safety and performance standards also play a role in the higher price points of electric vehicles. Understanding these factors is essential to grasp why EVs are currently more expensive than traditional gasoline-powered cars.

What You'll Learn

- Battery Technology: High-capacity batteries are costly, impacting EV prices

- Production Costs: Manufacturing EVs requires specialized equipment and skilled labor

- Supply Chain: Limited supply of raw materials drives up production costs

- Research & Development: Extensive R&D for innovation contributes to higher prices

- Government Incentives: Tax credits and subsidies can make EVs more affordable

Battery Technology: High-capacity batteries are costly, impacting EV prices

The high cost of electric vehicles (EVs) is a topic of much discussion and research, and one of the primary factors contributing to this expense is battery technology. At the heart of every EV is a battery, and the development of high-capacity, efficient batteries is a complex and costly process. These batteries are the power source for the vehicle, and their performance directly influences the overall driving experience and the car's value.

Battery technology has advanced significantly in recent years, but the challenge remains that high-capacity batteries are expensive to produce. This is primarily due to the use of advanced materials and the intricate manufacturing processes required. For instance, lithium-ion batteries, which are commonly used in EVs, rely on lithium, cobalt, and nickel as key components. These materials are not only rare but also subject to price volatility, which can significantly impact the cost of production. The extraction and processing of these materials involve specialized equipment and processes, adding to the overall expense.

The manufacturing process itself is intricate and requires precision. High-capacity batteries demand a high level of craftsmanship and specialized equipment to ensure optimal performance and safety. The assembly involves layering various components, including electrodes, separators, and electrolytes, which must be carefully aligned and connected. This level of precision and the specialized equipment needed contribute to the higher production costs. Moreover, the development and implementation of advanced battery management systems, which optimize performance and extend battery life, further add to the complexity and expense.

Another aspect to consider is the research and development (R&D) investment required to improve battery technology. Companies are constantly striving to enhance battery capacity, energy density, and charging efficiency. This R&D often involves extensive testing, experimentation, and innovation, all of which contribute to the high costs associated with battery production. As a result, these expenses are often passed on to consumers, making EVs more expensive compared to traditional internal combustion engine vehicles.

Despite the challenges, ongoing advancements in battery technology are driving down costs and improving efficiency. Researchers and engineers are exploring new materials, such as solid-state electrolytes and lithium-sulfur compounds, which could offer higher energy densities and lower production costs. Additionally, improvements in manufacturing processes and supply chain management are helping to reduce expenses. While the high cost of batteries remains a significant barrier to widespread EV adoption, the continuous development and refinement of battery technology will likely lead to more affordable and accessible electric vehicles in the future.

Hawaii's Electric Future: Unveiling Local EV Production

You may want to see also

Production Costs: Manufacturing EVs requires specialized equipment and skilled labor

The high cost of electric vehicles (EVs) can be attributed to several factors, and one of the primary reasons is the production process itself. Manufacturing EVs involves a complex assembly of various components, which demands specialized equipment and a highly skilled workforce. This aspect of production contributes significantly to the overall expense of these vehicles.

Specialized equipment is essential for the manufacturing process as it enables the precise assembly of EV components. For instance, the production of electric motors, batteries, and power electronics requires advanced machinery and tools that are specifically designed for these tasks. These machines often have tight tolerances and precise specifications, ensuring that the final product meets the required standards. The investment in such specialized equipment is substantial, and manufacturers need to recover these costs, which are then reflected in the vehicle's price.

Skilled labor is another critical factor in the production of EVs. Building an electric vehicle requires a team of highly trained professionals, including engineers, technicians, and assembly workers. These individuals possess specialized knowledge and expertise in areas such as electronics, mechanics, and battery technology. Their skills are crucial for ensuring the quality and reliability of the vehicle's performance. Skilled labor is often more expensive, and the need for extensive training and experience contributes to the higher production costs.

The manufacturing process of EVs involves intricate steps, from the initial assembly of the battery pack to the final integration of the electric motor and power train. Each stage requires precise coordination and specialized techniques. For example, the assembly of lithium-ion batteries demands careful handling and specific procedures to ensure safety and performance. The complexity of the production process, coupled with the requirement for skilled labor, results in higher operational costs for manufacturers.

In summary, the production costs associated with manufacturing EVs are substantial due to the need for specialized equipment and skilled labor. The investment in advanced machinery and the recruitment of highly trained professionals contribute to the overall expense of these vehicles. While the initial costs may be higher, the long-term benefits of reduced environmental impact and improved performance make EVs a desirable and sustainable choice for many consumers.

Electric Vehicles: Powering the Future, Yet Lacking Essential Features

You may want to see also

Supply Chain: Limited supply of raw materials drives up production costs

The high cost of electric vehicles (EVs) is a multifaceted issue, and one significant factor is the supply chain, particularly the limited availability of raw materials. The production of EVs requires a diverse range of materials, including lithium, cobalt, nickel, and rare earth elements. These materials are essential for the batteries, motors, and other critical components that power electric vehicles. However, the supply of these materials is constrained, leading to increased production costs.

The primary challenge lies in the geographical distribution of these raw materials. Lithium, for instance, is primarily sourced from South America, particularly Chile and Argentina. Cobalt, another crucial element, is predominantly found in the Democratic Republic of Congo. These regions are often politically unstable, and the extraction processes can be environmentally damaging. As a result, the supply of these materials is not only limited but also subject to geopolitical risks and environmental concerns.

The limited supply of raw materials has led to a situation where the prices of these commodities have skyrocketed. For example, lithium prices have more than doubled in the past few years, and cobalt prices have seen similar increases. These higher raw material costs are then passed on to the manufacturers, who, in turn, reflect these increased expenses in the form of higher vehicle prices. This is especially true for the production of lithium-ion batteries, which are the heart of most electric vehicles.

Furthermore, the demand for these raw materials is not only growing due to the increasing popularity of EVs but also from other industries, such as the energy storage sector and the development of new technologies. This dual demand further exacerbates the supply chain issues, as the limited availability of raw materials cannot keep up with the rising demand. As a result, manufacturers are often forced to pay higher prices for these materials, which directly impacts the overall cost of producing electric vehicles.

To address this challenge, the industry is exploring various strategies. One approach is to diversify the supply chain by identifying new sources of raw materials and developing more sustainable extraction methods. Another strategy involves recycling and reusing materials, which can help reduce the reliance on virgin resources. Additionally, advancements in technology and manufacturing processes are being pursued to optimize the use of these materials, thereby reducing the overall cost of production. Despite these efforts, the limited supply of raw materials remains a significant hurdle in making electric vehicles more affordable and accessible to a broader market.

Dominos' Electric Vehicle Mystery: Unveiling the Green Delivery Fleet's Location

You may want to see also

Research & Development: Extensive R&D for innovation contributes to higher prices

The high cost of electric vehicles (EVs) is often attributed to the extensive research and development (R&D) efforts invested in their creation. This is a critical aspect of the EV industry, as it directly impacts the overall price and performance of these vehicles. The R&D process for EVs is complex and multifaceted, requiring a deep understanding of various technologies and their integration.

One of the primary reasons for the high R&D costs is the development of advanced battery technology. Electric vehicles rely on powerful and efficient batteries to store energy, and the research in this field aims to improve energy density, charging speed, and overall battery life. Scientists and engineers are constantly pushing the boundaries to create more sustainable and cost-effective battery solutions, which is a significant factor in the higher price tags of EVs. For instance, developing solid-state batteries or improving lithium-ion technology requires substantial investment in materials science, chemistry, and engineering.

Additionally, the R&D process for EVs involves creating sophisticated electric powertrains. These powertrains must be highly efficient, powerful, and reliable, which demands extensive testing and refinement. Engineers work tirelessly to optimize motor performance, power electronics, and energy management systems, ensuring that the vehicle can deliver the desired range and performance while maintaining efficiency. This level of innovation and customization contributes to the higher production costs, as it requires specialized equipment and skilled labor.

Furthermore, the R&D focus on enhancing the driving experience and safety features also plays a role in the elevated prices. EVs are equipped with advanced driver-assistance systems, autonomous driving capabilities, and sophisticated infotainment systems. Developing and integrating these technologies requires significant R&D investments, ensuring that the vehicles meet or exceed the safety and comfort standards expected by consumers. As a result, the overall cost of production increases, reflecting the cutting-edge features and innovations that set EVs apart from traditional internal combustion engine vehicles.

In summary, the high cost of electric vehicles is, in part, a result of the extensive R&D efforts required to drive innovation in battery technology, electric powertrains, and advanced vehicle systems. While these investments contribute to the initial higher prices, they also position EVs as cutting-edge, sustainable, and technologically advanced alternatives to conventional automobiles. As the industry continues to evolve, the balance between R&D expenditure and market competitiveness will be crucial in shaping the future of electric mobility.

Boosting EV Range: Power Sources, Tech Innovations, and Sustainable Practices

You may want to see also

Government Incentives: Tax credits and subsidies can make EVs more affordable

The high cost of electric vehicles (EVs) is often attributed to various factors, including research and development, battery technology, and the relatively small scale of production. However, governments around the world have recognized the importance of promoting EVs to reduce carbon emissions and improve air quality. To encourage consumers to make the switch, many countries have implemented financial incentives in the form of tax credits and subsidies.

Tax credits are a direct financial benefit to consumers, reducing the overall cost of purchasing an EV. For instance, in the United States, the federal government offers a tax credit of up to $7,500 for the purchase of new electric vehicles. This credit can significantly lower the upfront cost, making EVs more accessible to a wider range of buyers. Similarly, in the UK, the Plug-in Car Grant provides up to £3,000 towards the cost of an electric car, which has been instrumental in boosting sales and reducing the average price of EVs on the market. These tax incentives not only make EVs more affordable but also stimulate the market by increasing demand and encouraging manufacturers to invest in EV production.

Subsidies, on the other hand, can take various forms, such as direct payments, grants, or reduced registration fees. For example, some governments offer cashback programs where consumers receive a percentage of the vehicle's price as a subsidy. This approach has been successful in countries like Norway, where the government provides a substantial subsidy, often exceeding the cost of a basic EV, making them highly competitive against traditional vehicles. Additionally, reduced registration fees and road tax for EVs are another form of subsidy, further lowering the long-term running costs for EV owners. These subsidies not only make EVs more attractive financially but also help in building a robust charging infrastructure, which is essential for the widespread adoption of electric vehicles.

The combination of tax credits and subsidies has proven to be a powerful tool in making electric vehicles more affordable and desirable. By reducing the initial purchase price and lowering ongoing costs, governments are effectively addressing two major barriers to EV adoption. This approach not only benefits individual consumers but also contributes to a more sustainable future by accelerating the transition to cleaner transportation methods. As a result, many countries are witnessing a rapid growth in the EV market, indicating that these government incentives are playing a crucial role in making electric mobility a reality for the masses.

EV Credit: Filing for Tax Benefits: A Guide

You may want to see also

Frequently asked questions

The primary reason is the cost of the battery pack, which is a significant component of an EV's price. These batteries are expensive to manufacture and purchase, and they account for a substantial portion of the vehicle's overall cost. Additionally, EVs often have more advanced technology and features, which contribute to the higher price tag.

Yes, many governments worldwide offer incentives to promote the adoption of electric vehicles. These incentives can include tax credits, rebates, or grants that reduce the upfront cost of buying an EV. Such programs aim to make electric vehicles more affordable and encourage consumers to make the switch from conventional cars.

Not necessarily. While it is true that EVs have fewer moving parts, which can lead to lower maintenance costs over time, the initial expense of replacing the battery pack can be high. However, as technology advances, battery costs are expected to decrease, making EVs more cost-effective in the long run. Regular maintenance, such as tire changes and brake services, is similar to that of traditional vehicles.

For some, yes. The higher upfront cost of EVs can be a significant consideration for buyers, especially those on a tight budget. However, the long-term savings and environmental benefits of electric vehicles are often cited as compelling reasons to make the investment. Many buyers also take advantage of lease or financing options, making ownership more accessible.

Absolutely. As the market for EVs grows, more and more used electric cars are becoming available. Buying a used EV can significantly reduce the cost, and with proper care, these vehicles can be reliable and efficient. Additionally, some manufacturers offer used car programs, providing certified pre-owned EVs with warranties, making them an attractive and cost-effective option.