Electric vehicles (EVs) have revolutionized the automotive industry, offering a cleaner and more sustainable mode of transportation. One intriguing aspect of EVs is their absence of traditional gear systems, which is a stark contrast to conventional internal combustion engine (ICE) vehicles. The question arises: why don't electric vehicles have gears? The answer lies in the fundamental differences between the two types of powertrains. Electric motors, powered by batteries, deliver instant torque, allowing EVs to accelerate swiftly and smoothly without the need for complex gear mechanisms. This design choice not only enhances performance but also contributes to the overall efficiency and simplicity of electric powertrains, making EVs a compelling and innovative choice in the automotive landscape.

What You'll Learn

- Motor Efficiency: Electric motors directly transmit power, eliminating the need for gear changes

- Torque Control: Electric vehicles can adjust torque instantly, bypassing the need for gear shifts

- Regenerative Braking: This feature recharges the battery, reducing the need for traditional braking systems

- Single-Speed Transmission: A single-speed transmission is sufficient for electric vehicles due to their instant torque

- Performance Consistency: Electric motors provide consistent performance across all speeds, eliminating the need for multiple gears

Motor Efficiency: Electric motors directly transmit power, eliminating the need for gear changes

Electric vehicles (EVs) have revolutionized the automotive industry, offering a more sustainable and efficient mode of transportation. One of the key reasons behind their success is the absence of traditional gearboxes, which is a significant departure from conventional internal combustion engine (ICE) vehicles. This design choice is primarily driven by the unique characteristics of electric motors and their ability to provide efficient power transmission.

Electric motors are inherently designed to directly transmit power to the wheels, eliminating the need for complex gear systems. Unlike ICE vehicles, where gears are essential for matching the engine's rotational speed to the required vehicle speed, electric motors can deliver full torque from a standstill. This is made possible by the direct current (DC) or alternating current (AC) supply, which provides a consistent and powerful output. As a result, EVs can accelerate quickly and smoothly, offering a responsive driving experience without the need for gear changes.

The efficiency of electric motors is a critical factor in their design. These motors are highly efficient at converting electrical energy into mechanical power, with minimal energy loss. This efficiency is further enhanced by the absence of gear changes, as gears can introduce friction and energy dissipation during the transmission process. By directly transmitting power, electric motors ensure that more of the electrical energy is converted into useful work, resulting in improved overall vehicle efficiency.

In traditional ICE vehicles, gear changes are necessary to maintain optimal engine speed and performance across various driving conditions. However, this process can lead to energy losses and reduced efficiency. Electric vehicles, on the other hand, can maintain a constant and optimal motor speed through the use of sophisticated control systems. These systems adjust the motor's speed and torque to match the driving conditions, ensuring efficient power delivery without the need for manual gear shifts.

The elimination of gear changes in electric vehicles has several advantages. Firstly, it simplifies the vehicle's mechanical system, reducing the number of moving parts and potential failure points. This simplicity contributes to lower maintenance requirements and increased reliability. Secondly, the direct power transmission allows for a more seamless and instantaneous response to driver inputs, enhancing the overall driving experience. Lastly, the absence of gear changes enables electric vehicles to achieve higher energy efficiency, making them more environmentally friendly and cost-effective in the long run.

Kia's Electric Revolution: Why PA Lags Behind

You may want to see also

Torque Control: Electric vehicles can adjust torque instantly, bypassing the need for gear shifts

Electric vehicles (EVs) have revolutionized the automotive industry, offering a unique driving experience that differs significantly from traditional internal combustion engine (ICE) cars. One of the most intriguing aspects of EVs is their ability to eliminate the need for traditional gearboxes, which are a staple in manual and automatic transmissions of conventional vehicles. This innovation is primarily attributed to their advanced torque control systems, which play a pivotal role in enhancing performance and efficiency.

Torque, a fundamental concept in mechanics, refers to the rotational force that drives the wheels and determines a vehicle's acceleration and towing capacity. In traditional cars, gear changes are necessary to manage torque effectively. Lower gears provide high torque for quick acceleration, while higher gears optimize speed and fuel efficiency. However, this process involves a mechanical shift, which can introduce delays and inefficiencies.

In contrast, electric vehicles harness the power of instant torque adjustment. When an EV driver presses the accelerator pedal, the electric motor responds immediately by delivering the required torque to the wheels. This rapid response is made possible by the direct connection between the motor and the wheels, eliminating the need for a complex transmission system. The motor's ability to adjust torque instantly ensures a smooth and powerful acceleration experience, providing a significant advantage over conventional vehicles.

The absence of gear shifts in EVs also contributes to improved efficiency. With no mechanical friction or energy loss associated with gear changes, electric motors can maintain higher efficiency levels. This efficiency is further enhanced by the ability to optimize torque distribution, ensuring that the vehicle's power is utilized effectively, especially during frequent stop-and-go driving or when navigating challenging terrain.

Moreover, the instant torque control in electric vehicles provides a unique driving feel. The motor's direct response to the driver's input creates a seamless and linear acceleration, eliminating the traditional 'gear shift' sensation. This characteristic is particularly appealing to drivers who value a smooth and responsive driving experience, making EVs a popular choice for urban commuters and enthusiasts seeking a more dynamic drive.

Beyond the Range: Uncovering EV's Hidden Limitations

You may want to see also

Regenerative Braking: This feature recharges the battery, reducing the need for traditional braking systems

Regenerative braking is a game-changer for electric vehicles (EVs), offering a more efficient and sustainable way to slow down and stop. This innovative technology harnesses the power of the vehicle's electric motor to recharge the battery during deceleration, effectively reducing the need for traditional friction-based braking systems. By converting kinetic energy back into electrical energy, regenerative braking not only improves the overall efficiency of the vehicle but also enhances its performance and driving experience.

When an EV is driven, the electric motor not only propels the vehicle forward but also acts as a generator during braking. As the driver applies the brakes, the motor switches to generator mode, capturing the kinetic energy that would otherwise be lost as heat. This energy is then fed back into the vehicle's battery pack, replenishing its charge. The process is similar to how a generator works in a power plant, but on a much smaller scale, tailored specifically for the vehicle's needs.

The beauty of regenerative braking lies in its ability to extend the vehicle's range. By reusing the energy that would typically be wasted during braking, EVs can travel further on a single charge. This is particularly beneficial for electric cars, which often have smaller, more efficient batteries compared to their internal combustion engine counterparts. With regenerative braking, the battery is not only recharged during deceleration but also during periods of low speed or idling, further optimizing energy usage.

This feature also contributes to a smoother and more responsive driving experience. Unlike traditional braking systems, which rely on physical friction to slow down the vehicle, regenerative braking provides a more linear and controlled deceleration. This is especially noticeable in stop-and-go traffic or when driving in urban areas, where frequent braking is required. The instant feedback and precision of regenerative braking can enhance driver confidence and make city driving more enjoyable.

Furthermore, regenerative braking systems are designed to work in conjunction with the vehicle's traditional braking mechanism, typically a disc or drum brake. This means that while regenerative braking significantly reduces the need for frequent, hard braking, the conventional brakes are still essential for emergency situations or when the vehicle's speed exceeds the regenerative braking system's capabilities. This dual-braking system ensures that EVs can offer the best of both worlds: efficient, eco-friendly braking and reliable safety.

The Pioneers of Electric Vehicles: A Historical Journey

You may want to see also

Single-Speed Transmission: A single-speed transmission is sufficient for electric vehicles due to their instant torque

Electric vehicles (EVs) have revolutionized the automotive industry, and one of the key reasons for their unique design is the absence of traditional gearboxes. This design choice is primarily attributed to the nature of electric powertrains and their ability to deliver instant torque.

In conventional internal combustion engine (ICE) vehicles, gears are essential to match the engine's speed and torque to the vehicle's requirements. However, electric motors operate very differently. They provide a high level of torque from a standstill, which means that a single gear ratio can effectively handle the entire speed range of the vehicle. This is in contrast to ICE vehicles, where multiple gears are needed to manage the varying torque and speed requirements during acceleration, cruising, and deceleration.

The instant torque of electric motors allows for a simple and efficient drivetrain. A single-speed transmission can be designed to optimize the vehicle's performance and efficiency. This transmission can handle the full range of speeds and torques required by the EV, from slow city driving to high-speed highway cruising. The absence of multiple gears reduces the complexity of the drivetrain, making it lighter, more compact, and more reliable.

Furthermore, the single-speed design simplifies the overall vehicle architecture. With fewer moving parts, the risk of mechanical failure is reduced, and maintenance requirements are lower. This is particularly advantageous for electric vehicles, as they are known for their reliability and low maintenance needs compared to traditional ICE cars.

In summary, the instant torque provided by electric motors is the primary reason why EVs can function efficiently with a single-speed transmission. This design choice not only simplifies the vehicle's mechanics but also contributes to the overall performance, efficiency, and reliability of electric vehicles, making them a compelling and sustainable transportation option.

NMC vs. NCA: Unlocking EV Battery Potential

You may want to see also

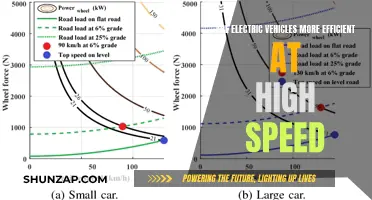

Performance Consistency: Electric motors provide consistent performance across all speeds, eliminating the need for multiple gears

Electric vehicles (EVs) have revolutionized the automotive industry, and one of the key reasons for their success is the absence of traditional gearboxes. This design choice is primarily attributed to the unique characteristics of electric motors, which offer a level of performance consistency that internal combustion engines (ICEs) cannot match.

Electric motors are inherently designed to deliver maximum torque from a standstill, a feature that is highly advantageous for EVs. Unlike ICEs, which require a specific gear ratio to match the engine's power band, electric motors can provide a constant and linear power output across a wide speed range. This means that when an EV accelerates, the electric motor delivers its full torque instantly, resulting in smooth and rapid speed increases. The absence of gears allows for a seamless and efficient power transfer, eliminating the need for complex gear changes and providing a more responsive driving experience.

The performance consistency of electric motors is a direct result of their design and operation. These motors use a combination of permanent magnets and electromagnets to generate torque. By controlling the flow of electricity to the electromagnets, the motor's speed and torque can be precisely adjusted. This fine-grained control enables the motor to maintain a consistent power output, regardless of the vehicle's speed. As a result, EVs can accelerate quickly and efficiently, providing a thrilling driving experience without the need for multiple gears.

Furthermore, the elimination of gears contributes to the overall efficiency and reliability of electric vehicles. Gearboxes, while efficient in their own right, introduce additional complexity and potential points of failure. With fewer moving parts, electric motors reduce the risk of mechanical issues and require less maintenance over their lifetime. This simplicity also allows for more compact and lightweight designs, further enhancing the overall performance and handling of EVs.

In summary, the consistent performance of electric motors across all speeds is a game-changer for the automotive industry. It enables EVs to offer a unique driving experience, combining instant torque, smooth acceleration, and efficient power transfer. This performance consistency, coupled with the reliability and efficiency of electric motors, is a significant factor in the widespread adoption and success of electric vehicles.

California Carpool Sticker: A Guide to Electric Vehicle Access

You may want to see also

Frequently asked questions

Electric vehicles are powered by electric motors, which provide a seamless and efficient power delivery system. Unlike ICEs, which require a mechanical transmission to transfer power from the engine to the wheels, electric motors can directly drive the wheels, eliminating the need for gears. This design simplifies the drivetrain, reduces weight, and improves overall efficiency.

The absence of gears in EVs offers several advantages. Firstly, it provides instant torque, resulting in quick acceleration and a responsive driving experience. Electric motors deliver full torque from a standstill, unlike ICEs, which require a certain engine speed (rpm) to generate maximum torque. Secondly, EVs often use single-speed transmissions, which simplify the drivetrain and allow for more efficient power transfer. This results in smooth and linear power delivery, making EVs fun to drive and offering a unique driving feel.

While the gearless design has its benefits, there are a few considerations. One challenge is the limited ability to adjust gear ratios on the fly, as electric motors provide a fixed relationship between speed and torque. This can impact performance in certain driving conditions, especially when starting from a standstill on steep inclines. However, advancements in technology, such as regenerative braking and sophisticated control systems, help mitigate these limitations. Additionally, the lack of traditional gears means that EVs may not offer the same level of low-end torque as ICE vehicles, but this is often compensated by the instant power delivery of electric motors.