Electric vehicles (EVs) have gained significant popularity in recent years, and one of the key factors contributing to their growing appeal is their weight. Compared to traditional internal combustion engine (ICE) vehicles, EVs are generally lighter. This is primarily due to the absence of heavy engine components and the use of lightweight materials in their construction. The reduced weight of EVs offers several advantages, including improved handling, enhanced acceleration, and increased energy efficiency. This paragraph introduces the topic of the weight of electric vehicles, highlighting the reasons behind their lighter nature and the benefits that arise from this design choice.

What You'll Learn

- Battery Weight: Lighter batteries enable longer range and faster charging

- Material Innovation: Advanced materials reduce vehicle weight without compromising safety

- Design Optimization: Streamlined designs minimize weight while maintaining structural integrity

- Efficiency Gains: Lighter EVs consume less energy, improving overall efficiency

- Performance Impact: Reduced weight enhances acceleration and handling

Battery Weight: Lighter batteries enable longer range and faster charging

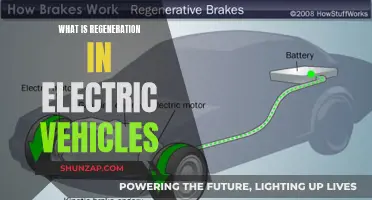

The weight of batteries is a critical factor in the performance and efficiency of electric vehicles (EVs). Lighter batteries have a significant impact on the overall weight distribution of the vehicle, which in turn affects its handling, acceleration, and range. One of the primary benefits of reducing battery weight is the potential for increased range. Electric vehicles rely on their batteries to power the electric motor, and a lighter battery pack means less weight to carry around, allowing for more efficient energy use. This efficiency translates to a longer driving range on a single charge, which is a major concern for potential EV buyers.

The concept of battery weight and range is closely tied to the energy density of the battery itself. Energy density refers to the amount of energy that can be stored in a given volume or weight. Lighter batteries with higher energy density can store more energy, enabling longer journeys without the need for frequent recharging. This is particularly advantageous for long-distance travel, where range anxiety is a common issue among EV owners.

Faster charging is another advantage that comes with lighter batteries. When a battery is lighter, it can accept and deliver power more efficiently during the charging process. This is because the reduced weight allows for quicker movement of ions within the battery, facilitating faster charging rates. As a result, EV owners can spend less time waiting for their vehicles to recharge, making the overall charging experience more convenient.

Additionally, the weight of the battery pack influences the overall performance and handling of the vehicle. A lighter battery distribution can improve the vehicle's power-to-weight ratio, resulting in quicker acceleration and better responsiveness. This is especially beneficial for sports-oriented EVs, where acceleration and handling are key selling points.

In summary, lighter batteries in electric vehicles offer a range of benefits, including increased driving range, faster charging times, and improved vehicle performance. As technology advances, the focus on reducing battery weight and improving energy density will continue to drive innovation in the EV market, making electric vehicles more appealing to a wider range of consumers.

Unlocking EV Tax Credits: A Guide to Maximizing Your Federal Benefits

You may want to see also

Material Innovation: Advanced materials reduce vehicle weight without compromising safety

The quest for lighter electric vehicles (EVs) is a driving force behind material innovation in the automotive industry. As the demand for more efficient and sustainable transportation grows, engineers and scientists are exploring advanced materials that can reduce vehicle weight while maintaining, and in some cases, enhancing safety. This pursuit of lightweighting is crucial for improving overall vehicle performance, range, and efficiency, which are key considerations for EV manufacturers.

One of the primary materials that have been instrumental in achieving this goal is carbon fiber. Carbon fiber composites have found their way into various automotive applications, particularly in high-performance EVs. These composites offer an exceptional strength-to-weight ratio, allowing for significant weight reduction without sacrificing structural integrity. For instance, the use of carbon fiber in the chassis and body panels of luxury EVs has become increasingly common, providing a stiffer and lighter alternative to traditional steel or aluminum components. This not only improves the vehicle's handling and acceleration but also contributes to a more efficient energy usage, as less power is required to accelerate the reduced vehicle mass.

Beyond carbon fiber, researchers and engineers are also exploring other advanced materials such as high-strength steel alloys and advanced polymers. These materials are designed to provide excellent strength and durability while being significantly lighter than conventional options. For example, advanced high-strength steel (AHSS) alloys offer improved formability and strength, enabling the creation of complex body structures that enhance crash safety. These steels can be used in critical areas like the vehicle's backbone, ensuring structural rigidity and passenger protection during collisions.

Additionally, the development of lightweight batteries is another crucial aspect of material innovation in EVs. Battery manufacturers are focusing on using advanced lithium-ion chemistries and innovative cell designs to reduce weight and increase energy density. This not only improves the overall weight distribution of the vehicle but also extends the driving range, addressing a significant concern for potential EV buyers. By utilizing lightweight materials in battery construction, such as advanced polymers and carbon fiber-reinforced composites, manufacturers can achieve a more balanced and efficient power source.

The integration of these advanced materials requires careful engineering and manufacturing processes. Automotive manufacturers are investing in research and development to optimize the use of these lightweight materials, ensuring they meet or exceed traditional safety standards. This includes rigorous testing and simulation to validate the structural integrity of vehicles built with these innovative materials. As a result, the industry is witnessing a new era of EVs that offer improved performance, extended range, and enhanced safety, all while being significantly lighter than their conventional counterparts.

Can Australia Lead the EV Revolution? Exploring Local Manufacturing Potential

You may want to see also

Design Optimization: Streamlined designs minimize weight while maintaining structural integrity

The pursuit of lightweight design in electric vehicles (EVs) is a critical aspect of their development, aiming to enhance performance, efficiency, and overall driving experience. This optimization process involves a meticulous approach to structural design, ensuring that every component contributes to the vehicle's weight reduction without compromising safety and durability. The primary goal is to achieve a harmonious balance between weight minimization and structural integrity, allowing EVs to offer a seamless blend of agility and robustness.

Streamlined designs play a pivotal role in achieving this objective. By employing aerodynamic principles and innovative engineering techniques, designers can create shapes that reduce drag, thereby decreasing the vehicle's overall weight. This is particularly evident in the sleek, curved exteriors of modern EVs, which not only enhance aesthetics but also contribute to improved fuel efficiency and reduced wind resistance. The use of lightweight materials, such as advanced composites and alloys, further aids in weight reduction, ensuring that the vehicle's structure remains robust yet lighter.

One of the key challenges in design optimization is maintaining structural integrity while minimizing weight. This involves a careful consideration of the vehicle's architecture, ensuring that critical components like the chassis, body, and battery pack are designed to withstand various loads and stresses. Advanced manufacturing techniques, such as laser welding and automated fiber placement, enable the creation of lightweight yet robust structures. These methods allow for precise control over the placement of materials, ensuring optimal strength-to-weight ratios in critical areas.

In the pursuit of lightweight designs, engineers must also consider the impact of weight distribution. A well-balanced weight distribution ensures optimal handling and stability, contributing to a more refined driving experience. This involves a meticulous arrangement of components, ensuring that the center of gravity is positioned low and central, enhancing the vehicle's agility and overall performance. By optimizing weight distribution, designers can further enhance the EV's dynamic capabilities, making it more responsive and enjoyable to drive.

Additionally, the use of advanced simulation tools and computational methods aids in the design process. These technologies enable engineers to virtually test and analyze different design iterations, predicting structural behavior and identifying potential weaknesses. Through this iterative process, designers can refine their creations, ensuring that the final product meets the desired weight reduction goals while adhering to strict safety standards. This approach not only accelerates the development cycle but also ensures a more efficient and effective design optimization process.

Exploring the World of Electric Cars: A Comprehensive Guide

You may want to see also

Efficiency Gains: Lighter EVs consume less energy, improving overall efficiency

The concept of electric vehicles (EVs) being lighter is not just a trend but a strategic design choice that significantly impacts their performance and efficiency. Lighter EVs have numerous advantages, and one of the most notable is the efficiency gains they offer. When an EV is designed with a focus on weight reduction, it directly contributes to improved energy consumption and overall efficiency.

In the world of automotive engineering, weight is a critical factor. Lighter vehicles require less energy to accelerate and maintain speed, which is a fundamental principle of physics. This is especially true for EVs, as they rely on electric motors and batteries for power. By reducing the weight of the vehicle, engineers can optimize the energy usage, ensuring that the electric motor works more efficiently. This efficiency gain is crucial for extending the range of EVs, a major concern for potential buyers.

The process of making EVs lighter involves several design considerations. One approach is to use lightweight materials such as advanced composites, high-strength steel, and aluminum alloys. These materials offer excellent strength-to-weight ratios, allowing engineers to create sturdy yet lightweight structures. For instance, the use of carbon fiber in certain EV models provides exceptional strength while significantly reducing weight. This strategic material choice is a key factor in achieving efficiency gains.

Additionally, the design of the EV's body and chassis plays a vital role. Streamlined shapes and optimized aerodynamics reduce drag, which is the force that opposes the motion of the vehicle. Lower drag coefficients mean less energy is required to overcome air resistance, further improving efficiency. This is particularly important for EVs, as reducing drag can lead to a noticeable increase in range.

The benefits of lighter EVs extend beyond just energy consumption. Improved efficiency also means reduced strain on the battery pack, allowing for longer-lasting performance. This is a significant advantage, as it addresses the concern of battery degradation over time. With lighter EVs, the battery can work more efficiently, providing a more consistent and reliable power source. As a result, drivers can enjoy longer journeys without the worry of frequent charging stops.

Unraveling the Mystery: WH MI in Electric Vehicles

You may want to see also

Performance Impact: Reduced weight enhances acceleration and handling

The reduced weight of electric vehicles has a significant performance impact, particularly in terms of acceleration and handling. This is a key advantage that sets electric cars apart from their traditional gasoline counterparts.

Firstly, the lower weight means that electric vehicles can accelerate more quickly. This is because the power-to-weight ratio is improved; with less mass to accelerate, the same amount of power can result in a more rapid increase in speed. This is a crucial factor in everyday driving, especially when merging onto highways or when quick reactions are needed in traffic. The instant torque delivery of electric motors further enhances this effect, providing a burst of power that can propel the vehicle forward with impressive acceleration.

Secondly, reduced weight contributes to improved handling and maneuverability. Lighter vehicles are generally easier to control and respond to driver inputs. This is particularly noticeable during cornering, where the reduced weight distribution allows for better weight transfer and a more stable ride. The handling characteristics of electric cars often provide a more responsive and engaging driving experience, making them fun to drive and offering a sense of precision and control.

The benefits of reduced weight in electric vehicles are further amplified by the efficient use of space and materials. Electric powertrains are often more compact and lightweight compared to traditional engines and transmissions. This efficient packaging allows for a lower center of gravity, which improves stability and handling. Additionally, the use of lightweight materials, such as carbon fiber and advanced composites, further reduces the overall weight without compromising on structural integrity.

In summary, the reduced weight of electric vehicles has a direct and positive impact on performance. It allows for quicker acceleration, improved handling, and a more engaging driving experience. These advantages are a result of the unique design and engineering approaches taken by electric car manufacturers, focusing on optimizing weight distribution and utilizing advanced materials. As the technology continues to evolve, we can expect further enhancements in performance, making electric vehicles even more appealing to drivers seeking a blend of efficiency and excitement.

The Dark Side of Electric Vehicle Ads: Misleading Claims and Greenwashing

You may want to see also

Frequently asked questions

Not necessarily. While many electric vehicles (EVs) do tend to be lighter due to the absence of a heavy internal combustion engine and associated components, this is not a universal rule. The weight of an EV depends on various factors, including its battery pack, electric motor, and other components. Some EVs might be lighter, but there are also heavier electric vehicles, especially those designed for specific performance or off-road capabilities.

The battery pack is a significant component in terms of weight. Modern electric vehicle batteries are typically made of lithium-ion cells, which are relatively lightweight. However, the number of cells and their overall arrangement can impact the vehicle's weight. Larger battery packs, which offer extended driving range, will generally add more weight. Manufacturers often optimize the battery design to minimize its impact on the vehicle's overall weight.

Yes, electric vehicles can offer some weight advantages. Firstly, EVs eliminate the need for heavy exhaust systems and associated components. Secondly, the electric motor and transmission in an EV are typically more compact and lightweight compared to a traditional engine and transmission. This reduction in weight can lead to improved handling, better acceleration, and increased efficiency.

Absolutely. Electric vehicle manufacturers often employ lightweight materials and innovative design techniques to reduce weight. For instance, many EVs use aluminum or carbon fiber composites for body panels and structural components, which are lighter than traditional steel. Additionally, the integration of various systems, such as the use of a single, centralized control unit, can help streamline the vehicle's architecture and reduce overall weight.