Electric vehicles (EVs) are revolutionizing the automotive industry, but their environmental impact and recyclability are important considerations. As the demand for EVs grows, it is crucial to understand the recycling potential of these vehicles to ensure a sustainable future. This paragraph will explore the recyclability of electric vehicles, examining the materials used in their construction and the processes in place to recycle them effectively. By delving into the challenges and opportunities, we can gain insights into how we can maximize the environmental benefits of EVs while minimizing their ecological footprint.

| Characteristics | Values |

|---|---|

| Recycling Potential | High. Electric vehicles (EVs) are designed with recyclable materials, and their components can be reused and repurposed. |

| Battery Recycling | Lithium-ion batteries, commonly used in EVs, can be recycled. However, the process is complex and requires specialized facilities. |

| End-of-Life Management | Many EV manufacturers offer take-back programs for retired batteries and vehicles, ensuring proper disposal and recycling. |

| Material Recovery | EVs use materials like aluminum, steel, copper, and rare earth elements, which can be recovered and recycled. |

| Environmental Impact | Recycling EVs can reduce the environmental impact compared to conventional vehicles, as it minimizes the need for raw material extraction. |

| Challenges | Recycling processes are still evolving, and there are challenges in collecting and transporting EV batteries to recycling centers. |

| Government Initiatives | Governments worldwide are promoting EV recycling through incentives and regulations, encouraging the development of recycling infrastructure. |

| Future Outlook | With the growing EV market, advancements in recycling technologies are expected to improve the efficiency and accessibility of EV recycling. |

What You'll Learn

- Battery Recycling: Efficient methods for recycling lithium-ion batteries

- Material Recovery: Techniques to extract valuable materials from EV components

- End-of-Life Management: Strategies for disposing of and recycling old electric cars

- Environmental Impact: Assessing the ecological benefits of EV recycling

- Infrastructure Development: Building recycling facilities to support EV waste management

Battery Recycling: Efficient methods for recycling lithium-ion batteries

The recycling of lithium-ion batteries from electric vehicles (EVs) is a crucial aspect of sustainable transportation, as it addresses the environmental impact of these powerful energy sources. With the growing popularity of EVs, the need to efficiently recycle their batteries has become increasingly important to minimize waste and ensure a circular economy. Here, we explore some efficient methods for recycling lithium-ion batteries, focusing on the processes that can effectively recover valuable materials while minimizing environmental harm.

One of the primary methods for recycling lithium-ion batteries is called 'hydrometallurgical processing.' This process involves dissolving the battery components in a chemical solution to separate the various metals and materials. The battery is first disassembled, and the lithium-ion cells are carefully removed. The cells are then immersed in a specific chemical solution, such as sulfuric acid, to dissolve the lithium cobalt oxide (LCO) cathode material. This step allows for the recovery of lithium, cobalt, and nickel, which can be reused in new batteries. The solution is then treated to recover these metals through various chemical processes, ensuring a high recovery rate. This method is energy-efficient and can handle large volumes of batteries, making it a preferred choice for industrial-scale recycling.

Another efficient technique is 'pyrometallurgy,' which utilizes high temperatures to melt and separate the battery materials. This process is particularly useful for recycling nickel-cadmium (Ni-Cd) and lead-acid batteries, which are commonly found in older EVs. Pyrometallurgy involves heating the battery components to extremely high temperatures, typically above 1000°C. This melting process separates the metals, allowing for the recovery of valuable materials like nickel, cobalt, and copper. The molten metal is then refined to obtain pure metals, which can be reused in various industries. While pyrometallurgy is effective, it requires careful handling due to the high temperatures involved and the potential release of toxic gases.

Mechanical processing is a more straightforward approach, focusing on physically separating the battery components. This method is often used in conjunction with other recycling techniques to enhance material recovery. It involves shredding or crushing the batteries to break them down into smaller pieces, making it easier to separate the various materials. The shredded battery is then sorted using mechanical separators, such as air classifiers or eddy current separators, to separate metals, plastics, and other components. This process ensures that the recovered materials are of high purity, making them suitable for reuse in manufacturing new batteries or other products.

In addition to these methods, research is ongoing to develop more advanced recycling technologies. For instance, some companies are exploring the use of supercritical water oxidation (SCWO) to break down battery materials at high temperatures and pressures, allowing for the recovery of lithium and other metals. Another innovative approach involves using biological processes, where certain bacteria can efficiently degrade and recycle battery materials. These emerging technologies aim to improve recycling efficiency, reduce energy consumption, and minimize the environmental impact of battery recycling.

In conclusion, recycling lithium-ion batteries from electric vehicles is essential for a sustainable future, and efficient methods are being developed to address this growing need. Hydrometallurgical processing, pyrometallurgy, mechanical processing, and emerging technologies like SCWO and biological recycling offer promising solutions. By implementing these efficient recycling methods, we can ensure that the valuable materials in EV batteries are recovered and reused, contributing to a circular economy and reducing the environmental impact of the transportation sector.

Maximizing Massachusetts EV Tax Benefits: A Comprehensive Guide

You may want to see also

Material Recovery: Techniques to extract valuable materials from EV components

The recycling of electric vehicles (EVs) is a crucial aspect of sustainable transportation, as it allows for the recovery of valuable materials and reduces the environmental impact of these vehicles. EVs are composed of various components, including batteries, motors, electronics, and structural parts, each containing different materials that can be recycled. The process of material recovery from EV components involves several techniques, which are essential to ensure a comprehensive and efficient recycling process.

One of the primary techniques for material recovery is disassembly, which involves carefully taking apart the vehicle to separate its components. This process requires skilled labor and specialized tools to handle the intricate design of EVs. The disassembly process begins with the removal of the battery pack, as it is a critical component containing hazardous materials. Specialized equipment is used to safely discharge and disconnect the battery, ensuring the safety of the recycling facility. Once the battery is removed, the vehicle's interior and exterior panels can be taken off, exposing the various electronic modules and motors.

After disassembly, the next step is material sorting and processing. This phase involves identifying and categorizing the different materials present in the EV components. Common materials in EVs include metals like aluminum, copper, and lithium, as well as plastics, ceramics, and rare earth elements. Advanced sorting techniques, such as magnetic separation, eddy current separation, and optical sorting, are employed to separate these materials efficiently. For instance, magnetic separation can extract iron and steel from the vehicle's frame and motors, while eddy current separation is used to remove non-ferrous metals like aluminum and copper.

The sorted materials then undergo further processing to recover their maximum value. For metals, this often involves shredding or granulating to reduce the size and prepare them for smelting or refining processes. Plastics, on the other hand, may be cleaned, sorted by type, and then recycled into new products. Rare earth elements, found in the vehicle's electronics and motors, can be extracted and recycled to produce new components, ensuring a circular economy for these valuable resources.

Finally, the recovered materials can be utilized in various ways. Metals, such as copper and aluminum, can be reused in manufacturing new vehicles or other products. Plastic components can be recycled into new automotive parts or other consumer goods. Rare earth elements, due to their limited availability, are particularly valuable and can be used in the production of high-tech devices and renewable energy technologies. This closed-loop recycling system ensures that the materials extracted from EVs are given new life, contributing to a more sustainable and circular economy.

Unlocking EV Tax Credit: Who Qualifies for Green Savings?

You may want to see also

End-of-Life Management: Strategies for disposing of and recycling old electric cars

The end-of-life management of electric vehicles (EVs) is a critical aspect of the automotive industry's sustainability efforts, as it addresses the growing number of EVs that will eventually require disposal and recycling. With the rapid adoption of electric cars, it is essential to establish efficient and environmentally friendly strategies for their end-of-life phase. Here's an overview of some key approaches to managing the disposal and recycling of old electric vehicles:

Recycling Processes and Materials: Electric vehicles are designed with various recyclable materials, including batteries, motors, and electronic components. When an EV reaches the end of its life, specialized recycling facilities can disassemble the vehicle to recover these valuable resources. The recycling process typically involves shredding the vehicle to reduce it to smaller pieces, which are then sorted and processed. The batteries, in particular, are a focus of recycling efforts due to their high-value materials like lithium, cobalt, and nickel. Advanced recycling techniques can extract and reuse these materials, reducing the need for mining and minimizing environmental impact.

Battery Recycling and Second-Life Applications: Battery recycling is a crucial aspect of EV end-of-life management. As EV batteries age, they may lose capacity and performance, making them unsuitable for continued use in vehicles. However, these batteries can find new life in other applications. Second-life battery packs can be utilized in energy storage systems, providing power for homes, businesses, or even feeding electricity back into the grid during peak demand. This approach extends the lifespan of the batteries and reduces the need for new material extraction. Many companies are investing in developing efficient recycling processes and second-life applications to ensure a sustainable future for EV batteries.

Disposal and Salvage: Proper disposal of non-recyclable components is essential to minimize environmental harm. While many parts of an EV can be recycled, some may contain hazardous materials that require specialized handling. For instance, the vehicle's engine, transmission, and certain electronic components might need to be disposed of or recycled separately. Salvage operations can recover usable parts, ensuring they are repurposed rather than discarded. This practice not only reduces waste but also provides an opportunity to extend the life of these components, potentially benefiting other industries or individuals in need of replacement parts.

Manufacturer Responsibility and Collaboration: Manufacturers of electric vehicles play a vital role in end-of-life management. They can develop comprehensive take-back programs, ensuring that retired EVs are properly recycled and their components are managed responsibly. Collaboration between automotive manufacturers, recycling companies, and government bodies is essential to establish standardized processes and infrastructure for EV recycling. This collaboration can lead to the development of specialized recycling facilities, trained personnel, and efficient collection systems, making the end-of-life management of EVs more accessible and environmentally friendly.

Consumer Awareness and Incentives: Educating consumers about the importance of proper EV disposal and recycling is crucial. Many people might not be aware of the environmental impact of discarding old electric cars or the available recycling options. Governments and automotive organizations can introduce incentives and awareness campaigns to encourage responsible end-of-life practices. These initiatives could include tax benefits for recycling, subsidies for second-life battery applications, or even manufacturer-led take-back programs, making it convenient and rewarding for EV owners to recycle their vehicles.

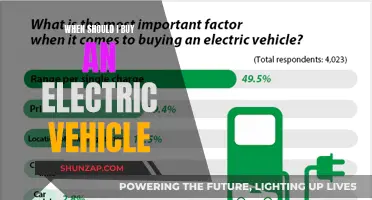

Electric Vehicles: A Smart Investment for a Sustainable Future?

You may want to see also

Environmental Impact: Assessing the ecological benefits of EV recycling

The environmental benefits of recycling electric vehicles (EVs) are significant and often overlooked. As the world transitions towards a more sustainable future, the proper disposal and recycling of EVs become crucial to minimizing their ecological footprint. Here's an assessment of the ecological advantages of EV recycling:

Reducing Environmental Pollution: One of the primary advantages of EV recycling is its role in reducing environmental pollution. Electric vehicles are designed to be more environmentally friendly than traditional internal combustion engine (ICE) cars. However, the manufacturing and disposal of EVs can still have an impact on the environment. Recycling processes aim to minimize this impact by recovering valuable materials from old EV batteries and components. For instance, lithium-ion batteries, commonly used in EVs, contain hazardous materials like lithium, cobalt, and nickel. Proper recycling ensures these materials are extracted and reused, preventing them from ending up in landfills or causing soil and water contamination.

Conservation of Natural Resources: Recycling EVs contributes to the conservation of natural resources. The manufacturing of electric vehicles requires substantial amounts of raw materials, including rare earth metals and precious metals. By recycling EVs, these valuable resources can be recovered and reused in new vehicle production. This process reduces the need for extensive mining and extraction, which often leads to habitat destruction and ecosystem disruption. For example, recycling EV batteries can provide a steady supply of lithium, a critical resource for the energy storage industry, ensuring its availability for future sustainable energy solutions.

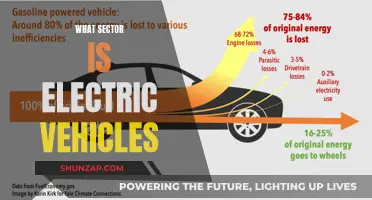

Lower Carbon Footprint: The ecological benefits of EV recycling extend to reducing the overall carbon footprint of the transportation sector. While EVs themselves produce zero tailpipe emissions, their production and disposal processes can still contribute to greenhouse gas emissions. Recycling helps mitigate this by reducing the energy-intensive manufacturing processes and minimizing the need for raw material extraction. Additionally, as the recycling industry improves, it can further lower the carbon emissions associated with EV disposal, making the entire lifecycle of these vehicles more environmentally friendly.

Promoting a Circular Economy: Implementing effective EV recycling practices encourages the development of a circular economy, where resources are utilized efficiently and waste is minimized. This approach aligns with the principles of sustainability and environmental conservation. By establishing robust recycling infrastructure, countries can ensure that EV batteries and components are responsibly managed, reducing the environmental impact of the automotive industry. Furthermore, the recycling industry can create new job opportunities and stimulate economic growth while contributing to a greener future.

In summary, recycling electric vehicles is an essential aspect of ensuring their environmental benefits are maximized. It helps reduce pollution, conserve natural resources, lower carbon emissions, and promote a sustainable circular economy. As the adoption of EVs continues to grow, investing in efficient recycling methods and infrastructure will be vital to maintaining a healthy and eco-conscious transportation system.

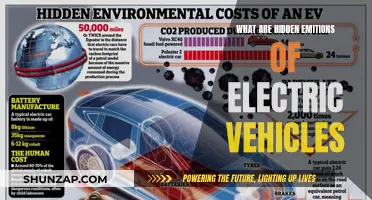

The Green Myth: Unveiling the True Environmental Impact of Electric Vehicles

You may want to see also

Infrastructure Development: Building recycling facilities to support EV waste management

The growing adoption of electric vehicles (EVs) brings with it a unique challenge: the need for efficient and specialized recycling infrastructure to manage the waste generated by these innovative vehicles. As the number of EVs on the road increases, so does the importance of establishing robust recycling facilities to ensure the sustainable end-of-life management of these vehicles. This is a critical aspect of the broader transition to a greener transportation ecosystem.

Infrastructure development plays a pivotal role in supporting the recycling of EVs. The process of recycling these vehicles is complex and requires specialized equipment and facilities to handle the unique components of EVs, such as lithium-ion batteries, advanced materials, and rare earth elements. Building comprehensive recycling centers can address the specific challenges associated with EV waste, ensuring that the environmental benefits of EVs are not undermined by improper disposal methods.

The first step in this infrastructure development is identifying suitable locations for these recycling facilities. Proximity to major EV manufacturing hubs or regions with high EV adoption rates can be advantageous. These locations can serve as central hubs for waste collection and recycling, reducing transportation costs and environmental impacts. Additionally, considering the availability of skilled labor and access to necessary resources is essential for the successful operation of these facilities.

Modern recycling facilities should be designed with advanced technology and processes to efficiently handle EV waste. This includes specialized equipment for battery disassembly and recycling, as well as systems for recovering valuable materials like cobalt, nickel, and lithium. The facilities should also have the capacity to process various EV models and components, ensuring a flexible and adaptable recycling system. Furthermore, implementing strict safety protocols is crucial to prevent accidents and protect workers and the environment.

In addition to the physical infrastructure, establishing comprehensive waste management networks is vital. This involves creating efficient collection systems for end-of-life EVs, ensuring that vehicles are properly transported to the recycling facilities. Collaboration between EV manufacturers, waste management companies, and government bodies can facilitate the development of these networks. By integrating recycling processes into the EV lifecycle, the industry can minimize environmental impact and maximize resource recovery.

In summary, building a robust infrastructure for EV recycling is essential to support the widespread adoption of electric vehicles. It involves strategic planning, specialized facility design, and the implementation of efficient waste management systems. By investing in these infrastructure developments, we can ensure that the benefits of EVs are sustained over the long term, contributing to a more sustainable and environmentally friendly future.

Is Atlanta Ready for the Electric Vehicle Revolution?

You may want to see also

Frequently asked questions

Yes, electric vehicles are recyclable, and the process involves specialized recycling techniques due to their unique components.

EV batteries typically contain lithium-ion cells, which can be recycled to recover valuable materials like lithium, cobalt, and nickel.

Recycling EVs requires more advanced processes as they have complex battery packs. These batteries need to be carefully disassembled and processed to extract materials while ensuring environmental safety.

One challenge is the large volume of batteries that need to be recycled, requiring efficient collection and transportation systems. Additionally, ensuring the proper disposal of hazardous materials is crucial.

Recovered materials can be reused in various industries. For instance, lithium can be used in new batteries, and other metals can find applications in electronics, construction, and even new vehicles, contributing to a more sustainable circular economy.