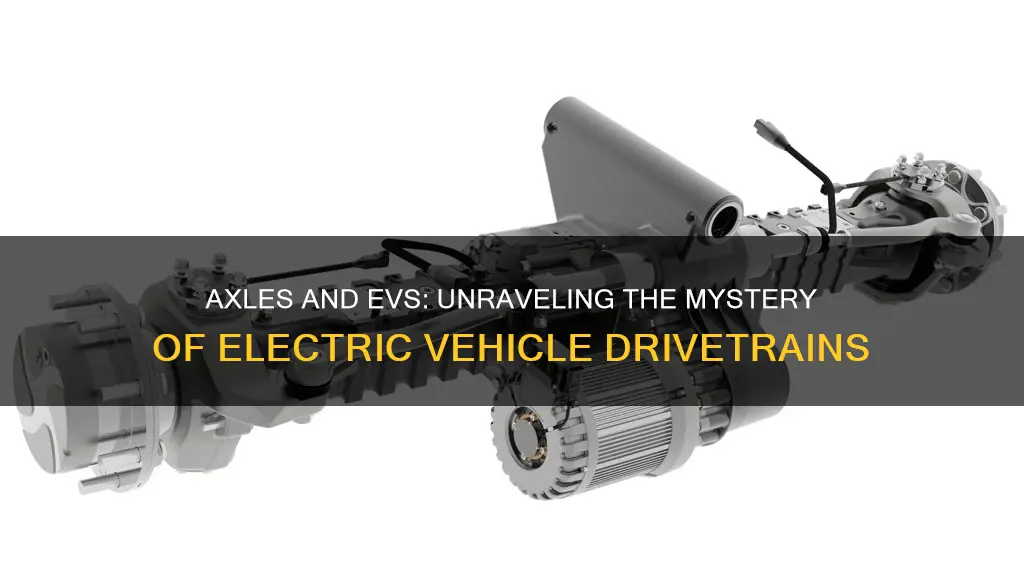

Electric vehicles (EVs) have revolutionized the automotive industry, but one question that often arises is whether they have axles. Unlike traditional internal combustion engine (ICE) vehicles, EVs operate on electric motors powered by batteries. The concept of an axle, which is a central component in conventional cars, is indeed different in electric vehicles. While EVs still utilize axles for wheel rotation and suspension, the absence of an internal combustion engine and its associated components leads to a unique design and functionality. This paragraph aims to explore the intricacies of axles in electric vehicles, shedding light on how they differ from their ICE counterparts and how they contribute to the overall performance and efficiency of electric cars.

| Characteristics | Values |

|---|---|

| Axle Configuration | Most electric vehicles (EVs) use a single axle for the front and rear wheels, similar to traditional cars. However, some EVs, especially those with extended ranges or specific design considerations, may have a dual-axle setup for the rear wheels. |

| Rear Axle Drive | In rear-wheel drive (RWD) EVs, the rear axle houses the electric motor and drives the rear wheels. This configuration is common in many popular EV models. |

| Front Axle Drive | Front-wheel drive (FWD) EVs typically have the electric motor and drive system on the front axle, providing power to the front wheels. This layout is often found in compact and affordable EVs. |

| All-Wheel Drive (AWD) | Some electric vehicles, particularly high-performance or off-road variants, offer all-wheel drive. In these cases, both the front and rear axles are powered, providing better traction and handling. |

| Axle Design | The design of the axles in EVs can vary. Some may have a more traditional solid axle design, while others might use independent suspension systems for improved ride quality and handling. |

| Weight Distribution | The placement of the electric motor and battery pack in EVs can influence weight distribution. This is crucial for handling, performance, and overall driving experience. |

| Axle Material | Modern EVs often use lightweight materials for axles, such as aluminum or advanced composites, to reduce overall vehicle weight and improve efficiency. |

| Axle Length | The length of the axles can vary depending on the vehicle's size, intended use, and design philosophy. |

| Axle Ratio | The ratio of the axle's length to its diameter can impact the vehicle's performance, especially in terms of acceleration and handling characteristics. |

| Axle-Related Innovations | EV manufacturers are constantly innovating with axle designs, including the use of advanced materials, improved cooling systems, and integrated drivetrain components to optimize performance and efficiency. |

What You'll Learn

- Axle Design: Electric vehicles often use unique axle designs for improved efficiency and performance

- Rear-Wheel Drive: Many EVs are rear-wheel drive, eliminating the need for a traditional front axle

- Motor Placement: Electric motors are typically mounted on the wheels, eliminating the need for an axle

- Independent Suspension: EVs often feature independent suspension, reducing the need for a rigid axle

- Hub Motor Systems: Some EVs use hub motors, where the motor is directly attached to the wheel, no axle needed

Axle Design: Electric vehicles often use unique axle designs for improved efficiency and performance

Electric vehicles (EVs) have revolutionized the automotive industry, and their unique requirements have led to innovative axle designs that enhance efficiency and performance. The traditional internal combustion engine (ICE) vehicles have been the standard for decades, but the rise of EVs has brought about a need for different mechanical systems to optimize power and range. One of the key areas of innovation is the axle, a critical component that connects the wheels to the vehicle's chassis.

Axle design in electric cars has evolved to accommodate the specific needs of electric powertrains. Unlike ICE vehicles, EVs do not require a complex transmission system to transfer power from the engine to the wheels. Instead, electric motors provide direct torque to the wheels, allowing for a more straightforward and efficient power transmission. This has led to the development of various axle configurations, each tailored to optimize performance and efficiency.

One notable trend in EV axle design is the use of single-speed transmissions or simplified gearboxes. In traditional ICE vehicles, complex transmissions are necessary to handle multiple gear ratios and provide the right torque at different speeds. However, electric motors offer a wide torque range, eliminating the need for multiple gears. As a result, EV manufacturers can design axles with fewer components, reducing weight and improving overall efficiency. This simplification also contributes to a more compact and lightweight vehicle structure.

Furthermore, electric vehicles often utilize advanced materials and manufacturing techniques to create specialized axles. For instance, the use of lightweight materials such as aluminum alloys and carbon fiber composites can significantly reduce the axle's weight without compromising strength. This weight reduction is crucial for improving the vehicle's overall efficiency, especially in electric powertrains where every kilogram matters. The design of the axle also considers the placement of the electric motor and other components to optimize weight distribution and ensure a balanced vehicle.

The unique axle designs in electric vehicles also focus on improving performance and handling. By utilizing advanced materials and manufacturing processes, engineers can create axles that provide better torque distribution and responsiveness. This is particularly important for high-performance EVs, where rapid acceleration and precise handling are essential. Additionally, the efficiency gains from optimized axle designs contribute to extended driving ranges, addressing a critical concern for potential EV buyers.

In summary, the axle design in electric vehicles has evolved to meet the demands of electric powertrains, resulting in unique and innovative solutions. These designs prioritize efficiency, performance, and lightweight construction. With the continuous advancements in EV technology, we can expect further improvements in axle engineering, making electric vehicles even more appealing to consumers.

Electric Vehicles: Revolutionizing Transportation with Cutting-Edge Technology

You may want to see also

Rear-Wheel Drive: Many EVs are rear-wheel drive, eliminating the need for a traditional front axle

The concept of rear-wheel drive (RWD) in electric vehicles (EVs) is a significant departure from traditional internal combustion engine (ICE) cars. In RWD EVs, the electric motor is typically mounted at the rear of the vehicle, driving only the rear wheels. This design choice has several advantages and is a key factor in the efficiency and performance of many modern EVs.

By eliminating the need for a front axle, RWD EVs can achieve a lower center of gravity, which improves handling and stability. This is particularly beneficial for high-performance EVs, as it allows for better weight distribution and a more agile driving experience. The absence of a front axle also contributes to a more compact and lightweight vehicle structure, which can enhance overall efficiency.

The rear-wheel drive layout in EVs often utilizes a single electric motor, which is more straightforward and efficient compared to the complex drivetrain systems found in traditional front-wheel drive (FWD) or all-wheel drive (AWD) vehicles. This simplicity can lead to reduced maintenance requirements and lower costs for EV owners.

Furthermore, RWD EVs can offer improved traction and performance on slippery surfaces. The rear-wheel drive configuration provides better weight transfer during acceleration and braking, allowing for more efficient use of the available torque. This is especially advantageous for high-performance EVs, where rapid acceleration and precise handling are desired.

In summary, rear-wheel drive is a prominent feature in many electric vehicles, offering a unique advantage by eliminating the traditional front axle. This design choice contributes to improved handling, efficiency, and performance, making RWD EVs a popular and innovative segment in the automotive industry.

Electric Vehicles: Revolutionizing the Automotive Industry

You may want to see also

Motor Placement: Electric motors are typically mounted on the wheels, eliminating the need for an axle

The placement of electric motors in electric vehicles (EVs) is a key factor in understanding the unique design and functionality of these vehicles. Unlike traditional internal combustion engine (ICE) cars, electric motors offer a different approach to power delivery, which influences their placement. One of the most notable differences is the absence of a traditional axle.

In conventional vehicles, the engine is usually mounted in the front or rear, and the power is transmitted to the wheels via an axle, which connects the wheels to the differential. However, electric motors operate on a different principle. These motors are often directly mounted onto the wheels themselves, eliminating the need for an axle. This design choice has several advantages and sets EVs apart from their conventional counterparts.

By placing the electric motor on the wheel, the power is transmitted directly to the wheel hub, providing a more efficient and direct drive system. This setup reduces the number of components and the length of the drive train, resulting in less energy loss and improved overall efficiency. The absence of an axle also means that the wheels can rotate independently, allowing for better handling and traction, especially in low-friction conditions.

This unique motor placement has another benefit: it contributes to a lower center of gravity. With the motor mounted on the wheel, the weight is distributed more evenly, improving the vehicle's stability and reducing the risk of rolling. This is particularly advantageous for high-performance EVs, where handling and cornering capabilities are essential.

In summary, the placement of electric motors on the wheels of electric vehicles eliminates the need for a traditional axle, offering a more efficient, direct drive system. This design choice not only reduces energy loss but also enhances vehicle stability and handling, showcasing the innovative approach that electric vehicles bring to the automotive industry.

Unleashing the Power of EVs: Strategies to Boost Demand and Revolutionize Transportation

You may want to see also

Independent Suspension: EVs often feature independent suspension, reducing the need for a rigid axle

Electric vehicles (EVs) have revolutionized the automotive industry, and one of the key aspects that set them apart from traditional internal combustion engine (ICE) vehicles is their suspension system. While the concept of an axle is still relevant in EVs, the way it is implemented has evolved significantly. One of the most notable differences is the use of independent suspension, which offers several advantages over the traditional rigid axle found in many ICE vehicles.

In conventional vehicles, a rigid axle is a common feature, connecting the wheels on either side of the vehicle. This design provides a simple and cost-effective solution for transmitting power and maintaining stability. However, it also has limitations, especially in the context of modern EVs. EVs often utilize independent suspension systems, which consist of multiple springs and shock absorbers attached to each wheel individually. This setup allows for better control and comfort, as each wheel can move independently, adapting to road imperfections and providing a smoother ride.

The primary benefit of independent suspension in EVs is the reduction of the need for a rigid axle. In traditional vehicles, the rigid axle serves as a structural component, but it can also lead to a harsher ride and less precise handling due to the limited flexibility. With independent suspension, EVs can achieve improved ride quality, better cornering capabilities, and enhanced overall performance. This is particularly advantageous for EVs, as they often prioritize efficiency and passenger comfort.

Independent suspension systems in EVs are designed to provide optimal control and stability. Each wheel's suspension allows for independent movement, ensuring that the vehicle can adapt to various road conditions. This level of flexibility is crucial for EVs, as they often have different weight distributions compared to ICE vehicles due to the placement of heavy batteries. The independent suspension helps maintain traction and stability, especially during high-speed maneuvers and when navigating through uneven terrain.

Furthermore, the use of independent suspension in EVs contributes to the overall efficiency and range of the vehicle. By optimizing the suspension design, EVs can reduce rolling resistance, improve energy efficiency, and enhance the overall driving experience. This technology is a significant factor in the success of modern EVs, as it addresses some of the historical challenges associated with traditional axle designs. As a result, EVs are becoming increasingly popular, offering a more sustainable and technologically advanced driving experience.

Unraveling BMS: Powering Electric Vehicles with Smart Battery Management

You may want to see also

Hub Motor Systems: Some EVs use hub motors, where the motor is directly attached to the wheel, no axle needed

The concept of hub motor systems is an innovative approach to electric vehicle (EV) design, offering a unique advantage in terms of mechanics and performance. In traditional internal combustion engine vehicles, an axle is a crucial component, transferring power from the engine to the wheels. However, in the world of EVs, the need for an axle can be eliminated through the use of hub motors.

Hub motors, also known as in-wheel motors, are electric motors that are integrated directly into the wheel hubs of a vehicle. This design choice has several implications and benefits. Firstly, by attaching the motor directly to the wheel, the need for a traditional transmission and axle is eliminated. This simplification of the drivetrain results in a more compact and lightweight vehicle, which can improve overall efficiency and performance.

The absence of an axle in hub motor systems brings about a unique driving experience. Since the motor is now part of the wheel itself, the power is transmitted directly to the wheel, providing instant torque and a more responsive drive. This setup allows for better control and handling, especially during acceleration and cornering, as the wheels can react more quickly to driver input.

Furthermore, the direct power transmission to the wheel can enhance traction and stability. With no intermediate components like an axle, the force is transferred more efficiently, ensuring that the wheels can grip the road surface effectively. This is particularly advantageous in low-traction conditions or during rapid maneuvers, where maintaining control and preventing wheel spin is crucial.

In summary, hub motor systems offer a novel way to power electric vehicles, eliminating the need for axles and providing a more efficient, responsive, and potentially safer driving experience. This technology showcases the continuous innovation in EV design, aiming to improve performance, handling, and overall driving pleasure.

Unveiling the Electric Vehicle Range: A Comprehensive Overview

You may want to see also

Frequently asked questions

Yes, electric vehicles, like traditional internal combustion engine (ICE) vehicles, typically have axles. An axle is a central shaft for a wheel or a gear, and it plays a crucial role in the vehicle's drivetrain. In EVs, the electric motor or the transmission is connected to the wheels via an axle, which allows for the transfer of power and enables the vehicle to move.

In electric vehicles, the axle system is responsible for transmitting the torque generated by the electric motor to the wheels. When the driver accelerates, the motor sends power through the transmission (if equipped) and then to the axle. The axle rotates, allowing the wheels to spin and propel the vehicle forward. This system is often more efficient and simpler compared to the complex gear arrangements in traditional ICE vehicles.

While the fundamental purpose of an axle remains the same, there can be some variations in design. Electric vehicles often use single-speed transmissions or simple gearboxes, which means the axle might have a fixed ratio. In contrast, conventional cars with manual transmissions may have multiple gears, requiring a more complex axle design. Additionally, some electric vehicles, especially those with rear-wheel drive, might have a solid axle, while front-wheel drive EVs often use independent front suspension with a drive shaft.