Copper plays a crucial role in the development and efficiency of electric vehicles (EVs). As a highly conductive metal, copper enables the transmission of electricity with minimal energy loss, which is essential for the operation of electric motors and the charging of batteries. Copper wiring and components are used throughout the EV's electrical system, from the battery pack to the motor and charging ports, ensuring efficient power distribution and optimal performance. This conductivity also contributes to the lightweight design of EVs, enhancing their overall efficiency and range. The use of copper in electric vehicles is a key factor in the widespread adoption of sustainable transportation, as it supports the reliable and sustainable operation of these vehicles.

What You'll Learn

- Copper's Role in EV Batteries: Copper enables higher energy density and faster charging in lithium-ion batteries

- Efficient Motor Wiring: Copper's conductivity reduces energy loss, improving motor efficiency and range

- Charging Infrastructure: Copper cables and connectors are essential for fast and safe charging stations

- Heat Management: Copper's thermal conductivity helps dissipate heat, ensuring battery and motor longevity

- Recycling and Sustainability: Copper's recyclability reduces environmental impact and supports the circular economy in EV production

Copper's Role in EV Batteries: Copper enables higher energy density and faster charging in lithium-ion batteries

The role of copper in electric vehicle (EV) batteries is a fascinating aspect of the technology that enables higher energy density and faster charging in lithium-ion batteries. Copper, a versatile and abundant metal, has become an essential component in the evolution of EV battery technology. Its unique properties make it a key enabler in the development of more efficient and powerful batteries.

One of the primary functions of copper in EV batteries is its role as a conductor. Copper is an excellent electrical conductor, allowing for efficient charge transfer within the battery. This property is crucial for the rapid and controlled movement of ions, which is essential for the charging and discharging processes. When an EV is plugged in, copper facilitates the flow of electrons, ensuring a quick and efficient charge. This enables the battery to store more energy in a shorter amount of time, resulting in faster charging times compared to batteries without copper.

In lithium-ion batteries, copper is often used as a current collector, a critical component that collects and distributes the electrical current generated during the charging and discharging cycles. This current collector is typically made of thin copper foil, which is coated onto the battery's anode and cathode. The copper foil provides a low-resistance path for the flow of electrons, ensuring that the battery can operate efficiently and safely. This design allows for a higher power output, which is vital for electric vehicles that require rapid acceleration and frequent starts.

Moreover, copper's role extends beyond conductivity. It also contributes to the overall structure and stability of the battery. Copper is used in the form of copper-clad steel or copper-coated aluminum foil, which provides structural support and protection for the battery's electrodes. This construction helps maintain the integrity of the battery, especially during the high-stress conditions of rapid charging and discharging. By ensuring the stability of the battery architecture, copper enables the development of batteries with higher energy density, allowing EVs to travel longer distances on a single charge.

The use of copper in EV batteries has led to significant advancements in the industry. It has allowed manufacturers to create more compact and lightweight batteries while maintaining or improving their performance. This is particularly important for electric vehicles, as it directly impacts their range and overall efficiency. With copper's ability to enhance energy density and charging speed, EV owners can enjoy a more convenient and satisfying driving experience.

In summary, copper plays a vital role in the development of electric vehicle batteries by enabling higher energy density and faster charging. Its excellent conductivity and structural support properties make it an indispensable material in the lithium-ion battery technology used in EVs. As the demand for electric vehicles continues to grow, the importance of copper in driving this technology forward becomes increasingly evident.

Illinois EV Tax Credit: A Green Incentive for Drivers

You may want to see also

Efficient Motor Wiring: Copper's conductivity reduces energy loss, improving motor efficiency and range

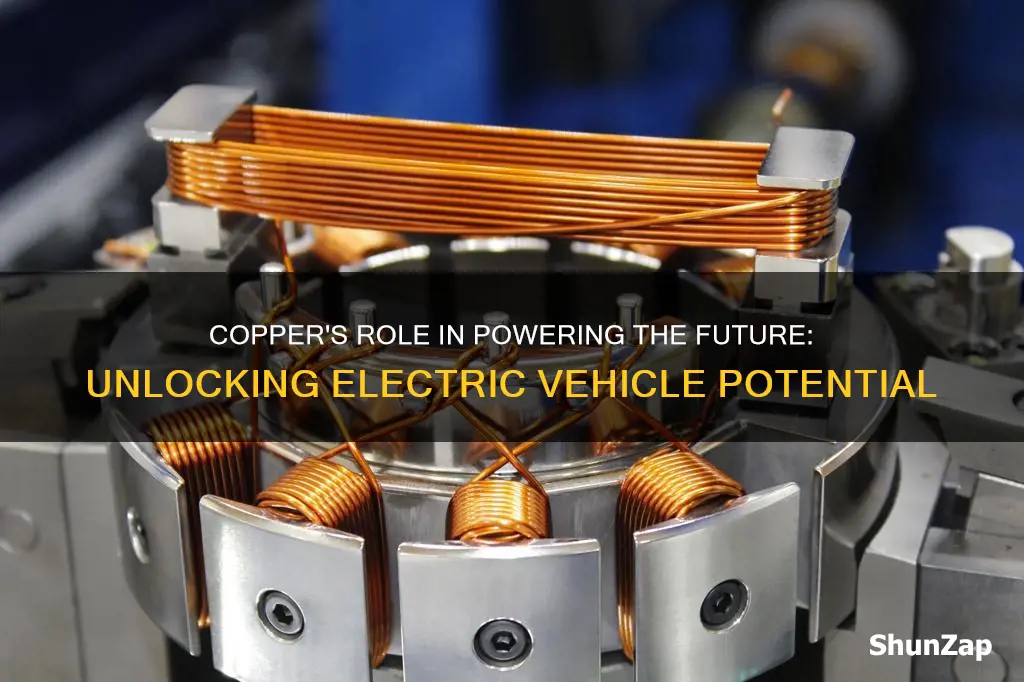

The role of copper in electric vehicles (EVs) is multifaceted, and one of its most critical applications is in the efficient wiring of electric motors. Copper's exceptional electrical conductivity plays a pivotal role in minimizing energy loss during the operation of these motors, thereby enhancing overall motor efficiency and extending the range of electric vehicles.

In electric motors, wiring is responsible for transmitting electrical power from the battery to the motor, enabling it to function. The efficiency of this process is crucial as any energy lost during transmission can result in reduced performance and range. Copper, with its superior conductivity, ensures that the electrical current encounters minimal resistance as it travels through the wiring. This reduction in resistance directly translates to a decrease in energy loss, allowing for more efficient power delivery to the motor.

The benefits of using copper in motor wiring are twofold. Firstly, copper's high conductivity ensures that the motor receives the precise amount of power required, optimizing its performance. This precision in power delivery is essential for maintaining the motor's efficiency, especially during varying load conditions. Secondly, the reduced energy loss due to copper's conductivity contributes to a more efficient overall system. This efficiency is vital for electric vehicles, as it directly impacts their range and ability to compete with traditional internal combustion engine vehicles.

The wiring used in electric motors is subject to high temperatures and mechanical stress, requiring materials that can withstand these demanding conditions. Copper meets these requirements, ensuring the longevity and reliability of the motor wiring. Its durability and resistance to corrosion make it an ideal choice for the harsh environments within electric vehicles. Additionally, copper's flexibility allows for easier installation and routing of wires, contributing to the overall design and manufacturing process of the vehicle.

In summary, copper's role in efficient motor wiring for electric vehicles is indispensable. Its superior conductivity directly reduces energy loss, leading to improved motor efficiency and extended range. Copper's ability to withstand the rigorous conditions of electric motors, combined with its flexibility and durability, makes it a key component in the advancement of electric vehicle technology. As the demand for efficient and sustainable transportation grows, copper's contribution to the performance and reliability of electric vehicles becomes increasingly significant.

The Hidden Heroes: Battery Producers for Electric Vehicles

You may want to see also

Charging Infrastructure: Copper cables and connectors are essential for fast and safe charging stations

The backbone of electric vehicle (EV) charging infrastructure relies heavily on copper cables and connectors, which play a critical role in ensuring fast and safe charging. As the demand for electric mobility continues to rise, the importance of efficient and reliable charging stations becomes increasingly evident. Copper, with its unique properties, is the ideal material to meet these demands.

Copper cables are designed to handle the high currents required for rapid charging, which is essential for EV owners who need to quickly replenish their vehicle's battery. The material's excellent electrical conductivity allows for minimal energy loss during the charging process, ensuring that the battery receives the maximum amount of power. This efficiency is crucial for reducing charging times, which is a key factor in the widespread adoption of electric vehicles.

In addition to conductivity, copper's durability and flexibility make it an ideal choice for charging station infrastructure. Copper cables can withstand the rigors of frequent use and environmental conditions, ensuring a long-lasting and reliable charging experience. The flexibility of copper allows for easy installation and routing, accommodating various charging station designs and layouts. This adaptability is particularly important in urban areas where space is limited and creative solutions are often required.

The connectors used in EV charging stations are also made from copper, ensuring a safe and secure connection between the charging station and the vehicle. Copper connectors provide excellent electrical conductivity, minimizing the risk of overheating and ensuring a stable power supply. Furthermore, copper's resistance to corrosion and oxidation means that these connectors remain reliable over extended periods, even in harsh weather conditions.

Investing in high-quality copper cables and connectors is essential for the development of a robust charging infrastructure for electric vehicles. As the industry continues to evolve, copper's versatility and performance will remain a cornerstone of the charging network, enabling the widespread adoption of electric mobility and contributing to a more sustainable future. This technology, driven by copper, is paving the way for a greener and more efficient transportation system.

Efficiently Peel Off Your EV Sticker: A Step-by-Step Guide

You may want to see also

Heat Management: Copper's thermal conductivity helps dissipate heat, ensuring battery and motor longevity

The efficient management of heat is a critical aspect of electric vehicle (EV) technology, and copper plays a pivotal role in this process. Electric vehicles rely on advanced battery systems and powerful electric motors, both of which generate significant amounts of heat during operation. This heat, if not properly managed, can lead to reduced performance, decreased efficiency, and even potential damage to the vehicle's components. Here's how copper's thermal conductivity is instrumental in addressing this challenge.

Copper's exceptional thermal conductivity is a key factor in heat dissipation. When an electric motor or battery operates, it produces heat due to the electrical resistance and mechanical friction within the components. Copper, with its high thermal conductivity, efficiently conducts this heat away from the source. This is particularly important in the case of electric motors, where the windings and other electrical components can become extremely hot during high-load conditions. By using copper for these components, the heat is rapidly transferred to the surrounding air or cooling systems, preventing overheating and ensuring the motor's longevity.

In the context of EV batteries, heat management is crucial for maintaining optimal performance and extending the battery's lifespan. Lithium-ion batteries, commonly used in EVs, are sensitive to temperature variations. Excessive heat can accelerate battery degradation, reduce energy density, and even pose safety risks. Copper's thermal conductivity is utilized in the design of battery packs to facilitate efficient heat dissipation. Copper heat sinks and cooling plates are often integrated into the battery design, allowing for the rapid transfer of heat generated during charging and discharging processes. This ensures that the battery operates within a safe temperature range, optimizing its performance and longevity.

The use of copper in heat management systems for EVs offers several advantages. Firstly, copper's lightweight nature contributes to overall vehicle efficiency, as it reduces the weight of the cooling system without compromising performance. Secondly, copper's excellent corrosion resistance ensures that the heat exchangers and conductors remain effective over extended periods, even in the challenging environmental conditions of an EV. Additionally, copper's ability to conduct heat away from critical components allows for more efficient and compact designs, making it easier to integrate heat management systems into the vehicle's architecture.

In summary, copper's thermal conductivity is a vital attribute in the design and operation of electric vehicles. By efficiently dissipating heat from electric motors and batteries, copper helps maintain optimal performance, ensures longevity, and enhances the overall efficiency of EV systems. As the demand for electric vehicles continues to grow, the role of copper in heat management will become increasingly significant, contributing to the widespread adoption of sustainable transportation solutions.

Electric Vehicle Mileage: Unlocking Efficiency and Range

You may want to see also

Recycling and Sustainability: Copper's recyclability reduces environmental impact and supports the circular economy in EV production

The recyclability of copper is a key factor in its role in the electric vehicle (EV) industry, offering significant environmental benefits and contributing to a more sustainable future. Copper, a highly conductive metal, is an essential component in the production of electric vehicles, playing a vital role in power transmission and energy efficiency. Its recyclability is a crucial aspect that reduces the environmental impact of EV manufacturing and supports the circular economy.

When it comes to recycling, copper stands out due to its excellent properties. It is 100% recyclable, meaning it can be recycled repeatedly without losing its inherent qualities. This is particularly important in the context of EV production, as the demand for copper in these vehicles is substantial. Electric motors, batteries, and charging systems all rely on copper's exceptional conductivity to ensure efficient power distribution and storage. By utilizing recycled copper, manufacturers can reduce the need for extracting new raw materials, which often involves energy-intensive processes and can have detrimental effects on the environment.

The recycling process for copper is highly efficient and environmentally friendly. It begins with collecting used or end-of-life products containing copper, such as old EV batteries or wiring. These materials are then sorted and processed to recover the copper. The recycling facility melts the copper and refines it, creating a high-purity metal that can be reused in various applications. This closed-loop system minimizes waste, reduces energy consumption, and lowers greenhouse gas emissions associated with primary copper production.

Furthermore, the recyclability of copper encourages the development of a circular economy in the EV industry. A circular economy aims to minimize waste and maximize resource efficiency by reusing and recycling materials. In the context of EVs, this means that copper, along with other recyclable materials, can be continuously recovered and repurposed. This approach reduces the strain on natural resources, decreases the carbon footprint of EV manufacturing, and promotes a more sustainable and environmentally conscious production process.

In summary, the recyclability of copper is a powerful aspect of its contribution to electric vehicle technology. It enables the reduction of environmental impact by minimizing the need for raw material extraction and reducing energy consumption. By embracing copper's recyclability, the EV industry can support the circular economy, ensuring a more sustainable and efficient approach to transportation. This aspect of copper's role in EVs is a testament to the material's versatility and its positive influence on the future of green technology.

Building Your Own Electric Car: A DIY Guide

You may want to see also

Frequently asked questions

Copper is a critical component in the power systems of electric vehicles (EVs). It is used extensively in the manufacturing of electric motors, transformers, and cables due to its excellent electrical conductivity and ductility. Copper's role is to efficiently transmit and distribute electrical energy, ensuring the vehicle's motor operates smoothly and with minimal energy loss.

The use of copper in EVs offers several advantages. Firstly, copper's high conductivity allows for the efficient transfer of power, resulting in improved performance and reduced energy consumption. This leads to longer driving ranges for electric vehicles. Additionally, copper's durability and resistance to corrosion make it ideal for the demanding conditions of EV batteries and charging systems.

Copper is essential in the development of efficient and reliable charging infrastructure for electric vehicles. Charging stations require robust electrical connections to handle the high currents involved in rapid charging. Copper's ability to carry electricity with minimal heat generation ensures safe and fast charging, making it a vital material for the widespread adoption of EVs.

While copper is a valuable resource, its extraction and processing can have environmental implications. However, the use of copper in EVs contributes to a more sustainable transportation system by reducing reliance on fossil fuels. The efficient energy transfer facilitated by copper helps lower greenhouse gas emissions, making electric vehicles an eco-friendly alternative. Proper recycling and responsible sourcing of copper can further minimize any potential environmental impact.