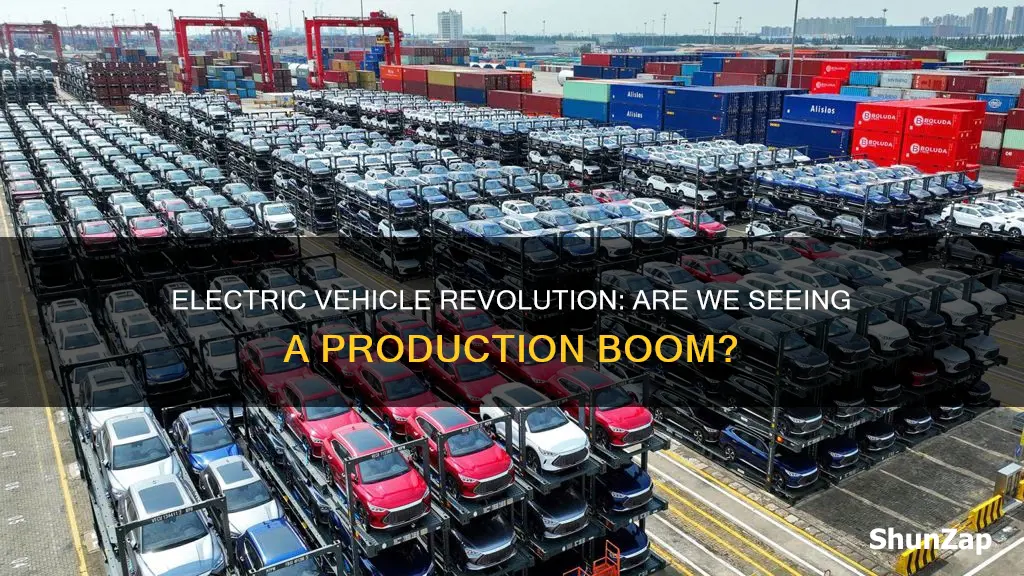

The electric vehicle (EV) market has seen significant growth and investment in recent years, with many major automakers entering the space. This surge in production and interest has led to a question: Is there a lot of production on electric vehicles? The answer is yes, with global production of EVs increasing steadily. This growth is driven by government incentives, environmental concerns, and technological advancements that have made EVs more affordable and efficient. As a result, many car manufacturers are now dedicating significant resources to EV production, with plans to expand their electric fleets. This shift towards electrification is transforming the automotive industry and reshaping consumer preferences, as more and more people opt for sustainable transportation options.

What You'll Learn

- Market Growth: Electric vehicle (EV) production has surged globally, with major automakers investing heavily

- Supply Chain Challenges: The rise in EV production faces supply chain disruptions, impacting battery and component availability

- Government Incentives: Governments worldwide offer incentives to boost EV production, driving market growth and innovation

- Environmental Impact: Increased EV production reduces carbon emissions, contributing to a greener transportation future

- Technological Advancements: Innovations in battery technology and charging infrastructure are key drivers of EV production growth

Market Growth: Electric vehicle (EV) production has surged globally, with major automakers investing heavily

The global electric vehicle (EV) market has witnessed an unprecedented surge in production and investment, marking a significant shift in the automotive industry. This rapid growth is primarily driven by the increasing demand for sustainable transportation solutions and the commitment of major automakers to reduce their environmental footprint. As a result, the once niche market for EVs is now experiencing mainstream adoption, with a wide range of models available across various price points.

One of the key factors fueling this growth is the substantial investment from traditional automakers. Companies like Tesla, Volkswagen, and General Motors have allocated billions of dollars to expand their EV production capabilities. Tesla, for instance, has become a pioneer in the EV space, with its Model 3 and Model Y becoming some of the best-selling vehicles in their respective segments. Volkswagen's ID.3 and ID.4, and General Motors' Chevrolet Bolt and upcoming Cadillac Lyriq, are also gaining traction, offering consumers more choices in the EV market. These investments have not only increased production volumes but also improved the overall quality and performance of electric vehicles, making them more appealing to a broader audience.

The surge in EV production is not limited to established automakers. Many new entrants and startups are entering the market, bringing fresh ideas and innovative technologies. Companies like Rivian, Lucid Motors, and Arrival are attracting significant attention with their all-electric SUVs and pickup trucks, challenging the dominance of traditional automakers. This influx of new players is further driving competition and innovation, leading to faster technological advancements and more affordable EV options.

Government incentives and subsidies also play a crucial role in this market growth. Many countries and regions are offering financial incentives, tax breaks, and grants to encourage the adoption of electric vehicles. These policies have made EVs more affordable for consumers, especially in the early stages of the market, and have contributed to the rapid increase in sales. As a result, automakers are responding by accelerating their production plans to meet the growing demand.

The global supply chain for EV components has also undergone significant changes to support this production boom. Battery technology, in particular, has seen substantial investments, with companies like Panasonic, LG Energy Solution, and Contemporary Amperex Technology (CATL) leading the way in lithium-ion battery production. The expansion of the supply chain has enabled automakers to scale up production efficiently, ensuring a steady supply of components to meet the rising demand for EVs worldwide. This comprehensive growth in the EV market is transforming the automotive industry, pushing traditional automakers to adapt and embrace electrification, and creating a more sustainable future for transportation.

Demystifying the Scrap Process: A Guide to Recycling Electric Vehicles

You may want to see also

Supply Chain Challenges: The rise in EV production faces supply chain disruptions, impacting battery and component availability

The rapid growth of electric vehicle (EV) production has indeed sparked a revolution in the automotive industry, but it also brings a unique set of challenges to the forefront, particularly in the realm of supply chain management. As the demand for EVs soars, the intricate web of suppliers and manufacturers is under pressure to keep up with the increasing production rates, which is not an easy feat. One of the primary supply chain challenges is the availability of critical components, especially batteries, which are the heart of any EV. The production of electric vehicles relies heavily on advanced lithium-ion batteries, and the demand for these has skyrocketed. However, the supply chain for battery manufacturing is complex and often constrained.

Battery production requires a vast array of raw materials, including lithium, cobalt, and nickel, which are sourced from various regions around the world. The extraction and processing of these materials involve multiple stages and can be susceptible to geopolitical tensions, environmental concerns, and logistical challenges. For instance, the mining of lithium, a key component, is primarily concentrated in a few countries, making the supply chain vulnerable to potential disruptions. As a result, the industry is facing a critical issue: the inability to meet the growing demand for batteries. This shortage is not just limited to the raw materials but also extends to the manufacturing processes and specialized equipment required for battery assembly.

Furthermore, the rise in EV production has led to a surge in the demand for other critical components, such as electric motors, power electronics, and advanced driver-assistance systems (ADAS). These components are not only essential for EV functionality but also contribute to the overall performance and safety of the vehicles. The supply chain for these parts is equally complex, with numerous suppliers and manufacturers involved. Delays in the delivery of these components can significantly impact the production timeline of EVs, causing a ripple effect throughout the entire supply chain.

To address these supply chain challenges, automotive manufacturers and suppliers are exploring various strategies. One approach is to diversify the supply base by sourcing materials and components from multiple regions to reduce the risk of disruptions. Additionally, companies are investing in research and development to improve battery technology, aiming to increase energy density and reduce the reliance on rare earth elements. Another critical aspect is the optimization of logistics and transportation networks to ensure timely delivery of components. This includes the development of more efficient distribution channels and the use of advanced tracking systems to monitor the movement of goods.

In conclusion, the surge in EV production has brought about significant supply chain disruptions, particularly in the realm of battery and component availability. The industry must navigate complex geopolitical and logistical challenges to ensure a steady supply of critical materials and parts. By implementing strategic initiatives, such as supply chain diversification and technological advancements, the EV sector can overcome these obstacles and continue its journey towards a more sustainable and environmentally friendly future.

Vehicle Chassis: Conducting the Electrical Circuit Path

You may want to see also

Government Incentives: Governments worldwide offer incentives to boost EV production, driving market growth and innovation

The global push towards electric vehicles (EVs) has been significantly influenced by government incentives and policies aimed at accelerating the transition to sustainable transportation. Many countries have recognized the importance of reducing greenhouse gas emissions and promoting cleaner energy sources, and as a result, they have implemented various strategies to encourage the production and adoption of electric cars.

One of the primary incentives is financial support for EV manufacturers. Governments often provide subsidies, grants, and tax benefits to companies investing in EV production facilities and research and development. These financial incentives help reduce the cost of production, making it more attractive for manufacturers to set up assembly lines and invest in the necessary infrastructure. For instance, countries like Norway, Germany, and France offer substantial tax credits and subsidies to EV producers, making these nations major players in the global EV market.

Incentives also extend to consumers to encourage the purchase of electric vehicles. Many governments have introduced purchase grants, rebates, and tax exemptions for EV buyers. These measures aim to make EVs more affordable and attractive to consumers, thereby increasing the overall demand for electric cars. For example, the United States' federal tax credit for EV purchases has been instrumental in driving sales, with popular models often reaching their sales limits due to the incentive program.

Additionally, governments are investing in charging infrastructure to support the widespread adoption of EVs. The establishment of a robust charging network is crucial for addressing range anxiety and ensuring convenience for electric vehicle owners. By providing incentives for the installation of charging stations in public areas, residential complexes, and workplaces, governments are making it more feasible for individuals to own and operate electric vehicles. This infrastructure development, coupled with consumer incentives, creates a positive feedback loop, further stimulating the market for EVs.

The impact of these government incentives is twofold. Firstly, it accelerates the growth of the EV market by making production and ownership more viable and affordable. Secondly, it fosters innovation in the automotive industry, as manufacturers strive to meet the demands of environmentally conscious consumers and government regulations. As a result, we are witnessing a rapid evolution in EV technology, with improved battery efficiency, faster charging, and the introduction of new, sustainable materials. This surge in production and innovation is a direct response to the supportive policies and incentives provided by governments worldwide.

Unleash India's EV Potential: A Guide to Starting Your Green Venture

You may want to see also

Environmental Impact: Increased EV production reduces carbon emissions, contributing to a greener transportation future

The rise in electric vehicle (EV) production is a significant development in the automotive industry, with far-reaching implications for the environment. As the world grapples with the urgent need to combat climate change, the shift towards electric mobility is a crucial step in the right direction. Increased production of EVs directly contributes to a greener transportation future, offering a more sustainable alternative to traditional internal combustion engine (ICE) vehicles.

One of the most notable environmental impacts of EV production is the reduction of carbon emissions. Internal combustion engines, prevalent in conventional cars, release substantial amounts of carbon dioxide (CO2) and other harmful pollutants during operation. In contrast, electric vehicles produce zero tailpipe emissions, meaning they do not release pollutants directly into the atmosphere. By transitioning to EV production, the transportation sector can significantly lower its carbon footprint, which is a major driver of global warming and environmental degradation.

The benefits of reduced carbon emissions extend beyond the vehicles themselves. As EV production increases, the overall environmental impact of the transportation industry becomes less severe. This is because the manufacturing process of EVs, while energy-intensive, typically has a lower carbon intensity compared to the production of conventional vehicles. Over time, the cumulative effect of reduced emissions from both vehicle operation and manufacturing can lead to improved air quality, less pollution, and a more sustainable environment.

Furthermore, the widespread adoption of EVs can stimulate the development of supporting infrastructure, such as charging stations and renewable energy sources. This infrastructure is essential to support the growing number of electric vehicles on the road. As more EVs are produced and sold, the demand for sustainable energy solutions increases, driving innovation and investment in green technologies. This, in turn, creates a positive feedback loop, where the increased production and use of EVs further reduce environmental impact.

In summary, the surge in EV production is a powerful catalyst for positive environmental change. By reducing carbon emissions from transportation, we can make significant strides towards a greener and more sustainable future. This shift in the automotive industry is a crucial step in mitigating the environmental challenges posed by conventional vehicles, offering a promising outlook for the planet's health and the longevity of our natural resources.

Subaru's Electric Revolution: Rumors and Speculations

You may want to see also

Technological Advancements: Innovations in battery technology and charging infrastructure are key drivers of EV production growth

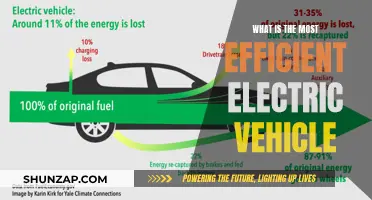

The electric vehicle (EV) market has witnessed a remarkable surge in recent years, with a significant focus on technological advancements that are driving this growth. One of the primary factors propelling the expansion of EV production is the continuous innovation in battery technology. Modern electric cars rely on advanced lithium-ion batteries, which have seen substantial improvements in energy density, allowing for longer driving ranges. This development is crucial as it addresses a major consumer concern: the anxiety associated with running out of power during long journeys. By increasing the range of EVs, manufacturers are making these vehicles more practical and appealing to a broader audience.

Battery technology advancements have also led to faster charging times, a significant improvement over the early days of EVs when charging a car could take several hours. Modern fast-charging stations can replenish a substantial portion of a battery's charge in under an hour, making the process more convenient and efficient. This development is vital for the widespread adoption of EVs, as it alleviates range anxiety and encourages potential buyers to make the switch from traditional internal combustion engine vehicles.

In parallel with battery innovations, the charging infrastructure for EVs has also undergone significant enhancements. The development of more efficient and powerful charging stations has played a pivotal role in supporting the growing number of EVs on the road. These stations can now handle higher power outputs, reducing charging times even further. Additionally, the integration of smart charging technologies allows for better grid management, ensuring that charging demands are met without overloading the power supply. This smart infrastructure is essential for the seamless integration of EVs into existing energy systems.

The combination of improved battery technology and an expanding charging network has created a positive feedback loop, further accelerating the growth of EV production. As more EVs hit the roads, the demand for efficient and convenient charging solutions increases, driving the development of new technologies and infrastructure. This cycle is vital for the long-term success of the EV market, as it ensures that the necessary support systems are in place to accommodate the growing number of electric vehicles.

In summary, the progress in battery technology and charging infrastructure is pivotal in the expansion of EV production. These innovations have not only improved the performance and convenience of electric vehicles but have also addressed critical barriers to adoption. With continued investment in research and development, the future of EV technology looks promising, paving the way for a more sustainable and environmentally friendly transportation ecosystem.

Kia K4: Electric or Not? Unveiling the Truth

You may want to see also

Frequently asked questions

The production of electric vehicles has been steadily increasing worldwide, with a significant surge in recent years. Many countries and regions are focusing on transitioning to electric mobility, leading to a rapid expansion in EV manufacturing. This growth is driven by government incentives, environmental regulations, and consumer demand for sustainable transportation options.

Yes, several regions have emerged as major hubs for electric vehicle production. For instance, China has become a global leader, with a vast network of EV manufacturers and a strong government push to dominate the electric car market. Europe is also witnessing a boom in EV production, with countries like Norway, Germany, and France investing heavily in electric mobility infrastructure and manufacturing.

Scaling up electric vehicle production comes with several challenges. One significant issue is the availability and cost of raw materials, especially lithium-ion batteries, which are crucial for EVs. Supply chain disruptions and the need for specialized manufacturing processes can also hinder rapid production growth. Additionally, the development of a robust charging infrastructure is essential to support the widespread adoption of electric vehicles.

The production processes for EVs and ICE vehicles differ significantly. Electric vehicles require advanced battery technology, electric motors, and sophisticated electronics, which can be more complex to manufacture. In contrast, traditional ICE vehicles have been produced for decades, and their assembly lines are well-established. However, the shift towards electrification is driving innovation in manufacturing processes, making EV production more efficient and cost-effective over time.

The future of electric vehicle production looks promising, with projections indicating a continued rise in production volumes. Many automotive manufacturers are investing heavily in EV technology and infrastructure, aiming to meet the growing demand for sustainable transportation. As the world moves towards a more environmentally conscious approach, the production of electric vehicles is expected to play a pivotal role in shaping the future of the automotive industry.