The market for electric vehicles (EVs) and portable electronics is vast, and a few companies have successfully bridged the gap between these two industries. One such company is Tesla, Inc., which is renowned for its electric cars and has also ventured into the production of advanced lithium-ion batteries for various applications, including cell phones and other mobile devices. Additionally, companies like Apple Inc. and Samsung Electronics Co. have their own battery divisions, producing high-capacity batteries for their respective smartphones and tablets. These companies not only sell electric vehicles but also play a significant role in the supply chain of cell phone batteries, showcasing their versatility and influence in the technology and automotive sectors.

What You'll Learn

- Market Share: Companies Dominating EV and Battery Sales

- Innovation: Tech Giants' Electric Vehicle and Battery Tech

- Supply Chain: Complex Networks for EV and Battery Production

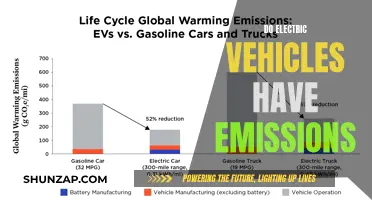

- Environmental Impact: Sustainable Practices in EV and Battery Manufacturing

- Consumer Trends: Demand for Electric Vehicles and Battery Packs

Market Share: Companies Dominating EV and Battery Sales

The market for electric vehicles (EVs) and lithium-ion batteries is rapidly evolving, with several key players dominating the industry. These companies are not only shaping the future of sustainable transportation but also influencing the technology behind portable electronics. Here's an overview of the market share and key players in both sectors:

Electric Vehicle Manufacturers:

- Tesla, Inc.: Undoubtedly, Tesla is the most prominent player in the EV market. With a significant market share, they have revolutionized the industry by offering high-performance electric cars, SUVs, and trucks. Tesla's innovative technology, over-the-air software updates, and direct-to-consumer sales model have set new standards. Their Gigafactories, designed for battery production, further emphasize their commitment to vertical integration.

- Volkswagen Group: This German automotive giant has made substantial investments in EVs, aiming to become a leader in the sector. Volkswagen's ID. series and Audi's e-tron lineup are well-received by consumers. The group's global reach and established supply chain make it a formidable competitor.

- BYD Company Limited: Based in China, BYD is a leading manufacturer of EVs and has a strong presence in the domestic market. They produce a range of vehicles, from buses to passenger cars, and have supplied batteries to various EV manufacturers worldwide. BYD's focus on sustainability and innovative designs has earned them a respected position in the industry.

Battery Manufacturers and Suppliers:

- Contemporary Amperex Technology (CATL): CATL is the largest manufacturer of lithium-ion batteries globally, supplying power units to numerous EV brands. They are known for their advanced technology, high energy density, and efficient production processes. CATL's market share in the EV battery market is substantial, and they have strategic partnerships with major automakers.

- Panasonic Corporation: With its extensive experience in battery technology, Panasonic has become a significant player in the EV battery supply chain. They have a joint venture with Tesla, called Tesla Panasonic, which produces batteries for the Model 3 and Model Y. Panasonic's expertise in electronics and battery technology makes them a trusted supplier.

- LG Energy Solution: This South Korean company is a leading manufacturer of lithium-ion batteries, catering to both the EV and consumer electronics markets. LG's advanced battery technology and global presence have contributed to its market dominance. They supply batteries to several major EV manufacturers and have a strong focus on research and development.

The EV and battery markets are highly competitive, with these companies driving innovation and shaping the industry's future. As the demand for sustainable transportation and portable electronics continues to grow, these dominant players will likely maintain their market share through technological advancements, strategic partnerships, and a commitment to sustainability.

Troubleshooting Short Circuits: A Guide to Vehicle Electrical Issues

You may want to see also

Innovation: Tech Giants' Electric Vehicle and Battery Tech

The intersection of electric vehicles (EVs) and battery technology is an exciting frontier, and several tech giants are at the forefront of this innovation. One such company that has been making significant strides in both the EV and battery sectors is Tesla, Inc. Tesla, founded by Elon Musk, has revolutionized the automotive industry with its electric cars and has also made substantial contributions to battery technology. Their cutting-edge battery designs and rapid charging capabilities have set new standards in the EV market.

In the realm of electric vehicles, Tesla has consistently pushed boundaries. The company's Model S, Model 3, and other variants have garnered critical acclaim for their performance, range, and sleek design. Tesla's vehicles are known for their advanced driver-assistance systems and over-the-air software updates, ensuring a constantly evolving and improved driving experience. Moreover, Tesla's Supercharger network provides fast charging, addressing a significant concern for potential EV buyers—range anxiety.

Tesla's expertise in battery technology is equally impressive. The company has developed proprietary battery packs, such as the 2170 cell, which offers higher energy density and improved performance. Their battery technology has not only powered their electric cars but has also been licensed to other manufacturers, further impacting the EV market. Tesla's vertical integration in battery production and design has allowed them to maintain control over quality and innovation.

Another tech giant making waves in this field is Apple Inc. While primarily known for its consumer electronics, Apple has been investing heavily in battery research and development. The company's acquisition of battery technology firm Passiv Technologies and its work on solid-state battery technology are notable. Solid-state batteries promise higher energy density, faster charging, and improved safety compared to traditional lithium-ion batteries. Apple's focus on this technology could potentially lead to breakthroughs in both EV and portable device battery performance.

Additionally, companies like Samsung and LG, known for their consumer electronics, have also ventured into the EV and battery space. Samsung has been developing solid-state batteries and has partnered with automotive manufacturers to supply its advanced battery technology. LG, another South Korean tech giant, has invested in EV battery production and is working on next-generation battery solutions, including solid-state and lithium-ion batteries with enhanced performance. These companies' contributions are vital in driving the widespread adoption of electric vehicles and improving battery technology.

The collaboration and competition among these tech giants are fostering rapid advancements in EV and battery technology. As a result, consumers can expect more efficient, sustainable, and high-performance electric vehicles with longer-lasting batteries. The synergy between these companies and their commitment to innovation will likely shape the future of transportation and energy storage, making electric mobility more accessible and appealing to a broader audience.

Mastering Vehicle Electrical Repairs: A Guide to Replacing Connectors

You may want to see also

Supply Chain: Complex Networks for EV and Battery Production

The automotive industry is undergoing a significant transformation with the rise of electric vehicles (EVs), and at the heart of this shift is the intricate supply chain that powers these sustainable modes of transport. The production of EVs and their batteries involves a complex network of suppliers, manufacturers, and logistics, all working in harmony to bring these innovative vehicles to market. This intricate web of connections is a testament to the industry's ability to adapt and innovate, ensuring that the demand for electric mobility is met with a reliable and efficient supply chain.

One of the key players in this supply chain is the company that sells both electric vehicles and cell phone batteries, a strategic move that highlights the interconnected nature of these industries. By offering a range of EVs and also supplying batteries for mobile devices, this company has created a unique and diverse portfolio. The production of electric vehicles requires a vast array of components, including advanced batteries, powerful motors, and sophisticated electronics. Simultaneously, the production of cell phone batteries demands high-quality, compact energy storage solutions. This dual focus allows the company to tap into multiple markets and build a robust supply chain infrastructure.

The supply chain for EVs and battery production is a complex web of relationships. It begins with raw material sourcing, where companies extract and process materials like lithium, cobalt, and nickel, which are essential for battery manufacturing. These materials are then transported to various manufacturers who assemble the batteries, ensuring they meet the specific requirements of electric vehicles. The batteries are then integrated into the vehicles, along with other critical components such as electric motors, power electronics, and charging systems. This intricate process requires a high level of coordination and collaboration between suppliers and manufacturers.

In the context of EV production, the supply chain also involves the development and implementation of advanced manufacturing processes. This includes the use of automated assembly lines, robotics, and sophisticated quality control systems to ensure the precision and reliability of each vehicle. The company's expertise in battery production for cell phones can be leveraged to optimize battery design, improve energy density, and enhance overall performance for EVs. By sharing technological advancements and best practices, the company can streamline its EV production supply chain, making it more efficient and cost-effective.

Furthermore, the logistics and distribution network plays a pivotal role in the success of this supply chain. Efficient transportation and delivery systems are crucial to ensure that components and finished products reach their destinations on time. This includes the management of inventory, warehousing, and the implementation of just-in-time inventory systems to minimize costs and maximize efficiency. The company's ability to navigate this complex network, fostering strong relationships with suppliers and logistics partners, is essential for maintaining a steady supply of raw materials and components, as well as delivering finished EVs to dealerships and customers.

In summary, the supply chain for EV and battery production is a multifaceted and intricate process, requiring a strategic approach to sourcing, manufacturing, and logistics. Companies that can integrate their operations, leveraging their expertise in both EV and battery production, will be well-positioned to succeed in this evolving market. By understanding and managing this complex network, these companies can drive innovation, ensure product quality, and meet the growing demand for sustainable transportation solutions.

Electric Vehicle Revolution: Are We Seeing a Production Boom?

You may want to see also

Environmental Impact: Sustainable Practices in EV and Battery Manufacturing

The intersection of electric vehicle (EV) manufacturing and battery production, particularly for cell phones, presents a unique opportunity to explore sustainable practices that can significantly reduce environmental impact. Companies that operate in both sectors are in a prime position to implement eco-friendly strategies, ensuring that their operations are not only innovative but also environmentally conscious.

One of the key environmental challenges in the EV and battery industry is the responsible sourcing of raw materials. Lithium, cobalt, and nickel are crucial for battery production, and their extraction often involves energy-intensive processes that can lead to habitat destruction and water pollution. For instance, lithium mining has been associated with environmental degradation in regions like the Salar de Uyuni in Bolivia. To address this, companies can adopt sustainable sourcing practices, such as implementing recycling programs for used batteries and supporting responsible mining initiatives. By encouraging the reuse and recycling of materials, they can reduce the need for excessive mining operations and minimize the environmental footprint of their supply chain.

In addition to responsible sourcing, the manufacturing processes themselves can be optimized to reduce environmental harm. EV and battery manufacturers can invest in energy-efficient technologies and renewable energy sources to power their production facilities. Solar panels, wind turbines, and hydroelectric systems can be integrated into factory infrastructure to reduce reliance on fossil fuels. For example, Tesla, a prominent player in both the EV and battery markets, has committed to using renewable energy for its manufacturing processes, aiming to become carbon-neutral by 2030. This approach not only reduces the company's carbon emissions but also sets a standard for sustainable manufacturing practices.

Furthermore, the development of closed-loop systems can significantly contribute to sustainability. This involves designing products with end-of-life considerations, ensuring that batteries and other components can be safely and efficiently recycled or reused. By implementing take-back programs, companies can recover valuable materials from retired batteries, reducing the demand for new raw materials and minimizing waste. This approach also encourages the development of a circular economy, where resources are utilized and reused, thereby decreasing the environmental impact of production.

Lastly, the adoption of green transportation methods for the distribution and delivery of EVs and batteries is essential. Electric or hydrogen-powered vehicles can be utilized for logistics, reducing the carbon emissions associated with traditional fuel-based transportation. This strategy not only applies to the company's internal operations but also to its supply chain, ensuring that the environmental benefits are extended throughout the entire production process.

In summary, the environmental impact of EV and battery manufacturing can be significantly reduced through a combination of sustainable practices. These include responsible raw material sourcing, adoption of renewable energy, implementation of closed-loop recycling systems, and the use of green transportation methods. By embracing these strategies, companies can not only minimize their ecological footprint but also contribute to a more sustainable future, ensuring that the benefits of electric mobility and portable energy storage are realized without compromising the health of our planet.

Unleash the Power of Electric Vehicles: A Guide to Sales Success

You may want to see also

Consumer Trends: Demand for Electric Vehicles and Battery Packs

The market for electric vehicles (EVs) and battery technology is experiencing a rapid evolution, driven by consumer trends and a growing awareness of environmental sustainability. As more consumers seek eco-friendly transportation options, the demand for electric vehicles has surged, creating a ripple effect throughout the supply chain, particularly in the battery sector. This shift in consumer behavior has led to a heightened focus on battery performance, longevity, and sustainability, prompting companies to innovate and diversify their offerings.

One of the key trends in the EV market is the increasing demand for longer-range vehicles. Consumers are now more inclined to choose electric cars with a range of over 300 miles, up from the previous preference for shorter-range models. This preference has led to the development of advanced battery packs that can provide higher energy density and faster charging capabilities. Companies like Tesla, for instance, have been at the forefront of this trend, continuously improving their battery technology to meet consumer expectations.

In parallel, the demand for battery packs is also rising in the consumer electronics sector, particularly for smartphones and other portable devices. As consumers demand longer-lasting batteries in their mobile phones, the market for high-capacity, efficient battery packs has expanded. This trend has created a symbiotic relationship between the EV and electronics industries, as companies that produce EV batteries are also developing solutions for the consumer electronics market. For example, companies like Contemporary Amperex Technology (CATL) and Panasonic are renowned for their expertise in both EV battery manufacturing and the production of high-performance batteries for smartphones and other devices.

The convergence of these two markets is evident in the strategic partnerships and collaborations between major players. Many automotive manufacturers are now investing in battery technology and forming alliances with battery producers to ensure a steady supply of advanced battery packs for their electric vehicle models. This trend not only drives innovation but also fosters a competitive environment, pushing companies to deliver superior products that cater to the diverse needs of consumers.

Moreover, consumer trends are also influencing the development of sustainable and eco-friendly battery solutions. With a growing emphasis on environmental consciousness, consumers are increasingly opting for batteries made from recycled materials and those that are easily recyclable at the end of their lifespan. This shift is prompting battery manufacturers to adopt more sustainable production processes and materials, ensuring that the demand for electric vehicles and battery packs aligns with the principles of a circular economy.

Ford's Electric Future: Shifting Focus or Staying Committed?

You may want to see also

Frequently asked questions

Tesla, Inc. is a well-known company that offers a range of electric vehicles, including cars, SUVs, and trucks, as well as produces and sells lithium-ion batteries, particularly for its energy storage systems and as a supplier to other manufacturers for cell phone and laptop batteries.

Yes, there are a few other companies that operate in both these sectors. For instance, Faraday Future is a startup that aims to design and manufacture electric vehicles, and it also has a focus on developing advanced battery technology. Another example is Contemporary Amperex Technology (CATL), a Chinese company that is a leading manufacturer of lithium-ion batteries for various applications, including electric vehicles and consumer electronics, such as cell phones.

These companies often leverage their expertise in one field to benefit the other. For instance, Tesla's experience in battery technology and energy storage systems, developed through its electric vehicle business, allows it to produce high-performance batteries for various applications. Similarly, companies like CATL, with their focus on battery manufacturing, can supply their technology to both the automotive and consumer electronics industries. This strategic approach enables them to diversify their product offerings and cater to multiple markets.