The rise of electric vehicles (EVs) has sparked a new wave of innovation in the automotive industry, and at the heart of this transformation is a powerful yet often overlooked component: the oil of electric vehicles. This term refers to the specialized lubricants designed specifically for the unique demands of electric powertrains. Unlike traditional internal combustion engines, EVs rely on electric motors and complex drivetrains, which require specialized oils to ensure optimal performance, longevity, and efficiency. These oils play a critical role in reducing friction, dissipating heat, and protecting critical components from wear and tear, ultimately contributing to the smooth operation and extended lifespan of electric vehicles.

What You'll Learn

- Battery Chemistry: Materials like lithium cobalt oxide power electric vehicles

- Energy Storage: Batteries store and release energy efficiently for EV propulsion

- Charging Infrastructure: Charging stations and grid integration enable EV battery replenishment

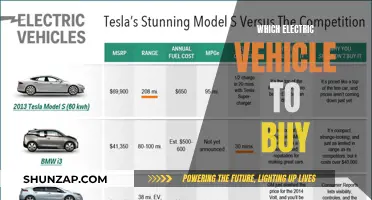

- Performance: EVs offer high torque, instant acceleration, and low emissions

- Environmental Impact: Production and disposal of EV batteries require sustainable practices

Battery Chemistry: Materials like lithium cobalt oxide power electric vehicles

The term "oil of electric vehicles" is a metaphorical way to describe the essential component that powers these vehicles, which is the battery. Just as oil was the lifeblood of internal combustion engines, the battery is the heart of electric vehicles (EVs). Among the various types of batteries used in EVs, lithium-ion batteries are the most prevalent due to their high energy density, long cycle life, and relatively low self-discharge rate. One of the key materials in these batteries is lithium cobalt oxide (LiCoO2), a compound that plays a critical role in the performance and efficiency of electric vehicles.

Lithium cobalt oxide is a type of lithium-ion battery cathode material. It is composed of lithium, cobalt, and oxygen atoms, arranged in a crystalline structure. This material is highly valued in the EV industry for several reasons. Firstly, it has a high specific capacity, meaning it can store a significant amount of lithium ions, which translates to a higher energy density. This is crucial for EVs, as it allows for longer driving ranges on a single charge. Secondly, LiCoO2 has a good thermal stability, which is essential for the safety of the battery, especially during high-temperature operations or in the event of a fire.

The structure of lithium cobalt oxide is fascinating and crucial to its performance. The material consists of a layered structure where lithium ions are sandwiched between layers of cobalt oxide. This arrangement allows for easy insertion and extraction of lithium ions during the charging and discharging processes. The layered structure also contributes to the material's stability and its ability to withstand repeated charge-discharge cycles without significant degradation.

However, lithium cobalt oxide batteries have some drawbacks. One of the main concerns is the cost of the material, which can be relatively high due to the limited availability of cobalt. Additionally, these batteries are sensitive to temperature changes, which can affect their performance and safety. To mitigate these issues, researchers and engineers are exploring various strategies, such as developing new cathode materials with improved performance and cost-effectiveness, or enhancing battery management systems to optimize temperature control.

In summary, lithium cobalt oxide is a critical component in the battery chemistry of electric vehicles, offering high energy density and thermal stability. While it presents some challenges in terms of cost and temperature sensitivity, ongoing research and development efforts aim to address these issues, ensuring that the "oil of electric vehicles" continues to power the transition to a more sustainable transportation future.

NMC vs. NCA: Unlocking EV Battery Potential

You may want to see also

Energy Storage: Batteries store and release energy efficiently for EV propulsion

The concept of "oil" for electric vehicles (EVs) is often associated with the energy storage system that powers these vehicles, which is indeed a crucial component. While traditional internal combustion engines rely on liquid petroleum gasoline or diesel, EVs depend on a different kind of "fuel" – electricity, stored in batteries. These batteries are the energy reservoirs that enable EVs to travel and are often referred to as the "heart" of the vehicle.

Energy storage in the form of batteries is a critical aspect of EV technology. It allows for the efficient storage and release of energy, ensuring that the vehicle has the power it needs to move. The primary function of these batteries is to store electrical energy, which is then used to propel the vehicle. This stored energy is a result of the charging process, where electricity is fed into the battery pack, typically through a charging port or a wireless charging system.

Modern EV batteries are designed to be highly efficient and reliable. They are composed of multiple cells, each capable of storing a small amount of energy. These cells are arranged in packs, providing the high-energy density required for EV propulsion. The energy storage capacity of these batteries varies, with some models offering longer ranges than others, depending on the size and type of the battery pack.

The efficiency of energy storage and release is a key factor in the performance and appeal of EVs. When the driver engages the accelerator, the battery releases the stored energy, powering the electric motor. This process is highly efficient, with minimal energy loss, ensuring that the vehicle can accelerate quickly and smoothly. The ability to store and release energy efficiently also contributes to the overall driving experience, providing a consistent and responsive performance.

Furthermore, the development of advanced battery technologies continues to enhance the capabilities of EVs. Researchers and engineers are constantly working on improving battery performance, including increasing energy density, reducing charging times, and extending the lifespan of the batteries. These advancements are vital to making EVs more practical and competitive with traditional vehicles, addressing range anxiety and charging infrastructure concerns.

Green Revolution: Are Electric Vehicles the Eco-Friendly Choice?

You may want to see also

Charging Infrastructure: Charging stations and grid integration enable EV battery replenishment

The evolution of electric vehicles (EVs) has sparked a revolution in the automotive industry, offering a sustainable and eco-friendly alternative to traditional internal combustion engine cars. At the heart of this transformation lies the concept of 'the oil of electric vehicles,' a metaphorical term that emphasizes the critical role of charging infrastructure in sustaining the EV ecosystem. This infrastructure is the lifeblood that keeps EVs on the road, ensuring their batteries are replenished and ready for the next journey.

Charging stations are the physical manifestations of this charging infrastructure, strategically located to provide EV owners with convenient access to power. These stations are the fuel pumps of the electric world, offering a rapid and efficient way to recharge batteries. Modern charging stations come in various forms, including slow, fast, and rapid chargers, each catering to different needs. Slow chargers, typically used for overnight charging at home, provide a steady and controlled replenishment of battery power. Fast chargers, found at many public stations, offer a quicker boost, allowing drivers to top up their batteries during brief stops. Rapid chargers, the fastest among the three, are ideal for quick breaks and can significantly extend the range of an EV in a matter of minutes.

The design and placement of these charging stations are crucial to the widespread adoption of EVs. A well-planned network of charging stations can alleviate range anxiety, a common concern among potential EV buyers. By strategically placing stations along highways, in urban areas, and at popular destinations, charging infrastructure becomes an enabler of freedom, allowing EV owners to embark on longer journeys without the fear of running out of power. This strategic placement also encourages the development of a robust EV market, as potential buyers are assured of convenient charging options.

Grid integration plays a pivotal role in the overall charging infrastructure. It involves the seamless interaction between the EV battery and the electrical grid, optimizing the charging process and managing energy distribution efficiently. When an EV is connected to a charging station, it can draw power from the grid, and through grid integration, the system can monitor and control the charging process. This technology ensures that charging sessions are efficient, preventing overloading the grid and promoting a balanced energy distribution. During periods of low demand, excess energy can be stored in the EV battery, and later, this stored energy can be fed back into the grid, contributing to a more sustainable energy model.

In summary, charging infrastructure, comprising charging stations and grid integration, is the vital component that transforms electric vehicles from innovative concepts into practical, everyday transportation. It provides the means to replenish EV batteries, ensuring they are always ready for use. With a well-developed charging network, the widespread adoption of EVs becomes a reality, paving the way for a greener and more sustainable future on our roads. As the EV market continues to grow, investing in and optimizing charging infrastructure will be essential to support this technological shift.

Ford's Electric Future: Profits and Prospects

You may want to see also

Performance: EVs offer high torque, instant acceleration, and low emissions

Electric vehicles (EVs) have revolutionized the automotive industry, offering a compelling alternative to traditional internal combustion engine (ICE) cars. One of the most significant advantages of EVs is their performance characteristics, which set them apart from conventional vehicles. At the heart of this performance lies the concept of high torque, instant acceleration, and remarkably low emissions.

Torque, a fundamental measure of an engine's rotational force, is a critical factor in determining a vehicle's performance. EVs deliver an impressive amount of torque from a standstill, providing a powerful and responsive driving experience. This is particularly noticeable when accelerating from a stop, where EVs excel due to their electric motors' ability to generate maximum torque instantly. Unlike ICE vehicles, which often require a certain speed to reach peak torque, EVs can deliver their full force right from the beginning of the drive, resulting in a smooth and rapid acceleration that is both thrilling and efficient.

The instant acceleration of EVs is a game-changer for drivers. It translates to a quick response when you press the accelerator, allowing for swift maneuvers and a more engaging driving experience. This is especially beneficial in urban areas with frequent stops and starts, as EVs can seamlessly navigate through traffic with ease. The lack of traditional gear shifts in EVs further enhances this performance, as there is no delay in power delivery, ensuring a seamless and instantaneous response to driver input.

Furthermore, the environmental benefits of this performance are significant. The high torque and instant acceleration of EVs are achieved without the need for a large, powerful engine. This results in lower emissions of harmful pollutants and greenhouse gases, contributing to a cleaner and more sustainable environment. The absence of the traditional exhaust system and the use of electric motors instead of gasoline engines mean that EVs produce zero tailpipe emissions, making them a greener choice for environmentally conscious consumers.

In summary, the performance of EVs, characterized by high torque, instant acceleration, and low emissions, is a key factor in their growing popularity. These attributes provide drivers with a unique and satisfying driving experience while also promoting a more environmentally friendly approach to transportation. As technology advances, EVs continue to evolve, offering even more impressive performance metrics and further solidifying their position as a viable and attractive alternative to conventional vehicles.

Is Toyota CH-R an Electric Vehicle? Unveiling the Truth

You may want to see also

Environmental Impact: Production and disposal of EV batteries require sustainable practices

The environmental implications of electric vehicle (EV) technology extend beyond the reduction of tailpipe emissions. A critical aspect often overlooked is the production and disposal of EV batteries, which can have significant ecological consequences if not managed sustainably. These batteries, primarily composed of lithium-ion cells, are the power source for EVs, and their manufacturing and end-of-life processes demand careful consideration.

The production of EV batteries involves a complex supply chain, starting with the extraction of raw materials. Lithium, for instance, is a key component, and its mining can lead to environmental degradation, including soil erosion and water pollution. The process often requires large amounts of energy, contributing to carbon emissions. Additionally, the extraction of other materials like cobalt and nickel, essential for battery cathodes, has been associated with human rights issues and environmental damage in certain regions. To ensure the sustainability of EV batteries, it is crucial to implement responsible sourcing practices, promoting the use of recycled materials and supporting eco-friendly mining techniques.

As the demand for EVs rises, so does the need for efficient and environmentally friendly recycling methods. The disposal of spent batteries is a critical challenge, as they contain hazardous materials. If not recycled properly, these batteries can release toxic substances into the environment, posing risks to ecosystems and human health. Advanced recycling technologies, such as hydrometallurgical and pyrometallurgical processes, can recover valuable metals while minimizing environmental impact. Governments and manufacturers should collaborate to establish comprehensive recycling infrastructure, ensuring that EV batteries are safely and sustainably managed at the end of their useful life.

Furthermore, the development of circular economy principles in the EV industry is essential. This approach focuses on minimizing waste and maximizing resource efficiency. By designing batteries with easy disassembly and using recyclable materials, manufacturers can reduce the environmental footprint. Implementing take-back programs and incentivizing consumers to return used batteries can facilitate proper recycling and encourage the reuse of materials.

In summary, the environmental impact of EV batteries is a multifaceted issue. To address this, sustainable practices should be adopted throughout the production and disposal lifecycle. This includes responsible raw material sourcing, efficient recycling methods, and the adoption of circular economy principles. By doing so, the EV industry can contribute to a greener future, reducing the environmental concerns associated with the 'oil' of electric vehicles, which, if not managed sustainably, could become a new form of environmental challenge.

Exploring the Four Types of Electric Vehicles: A Comprehensive Guide

You may want to see also

Frequently asked questions

The term "oil" in the context of electric vehicles (EVs) is often used metaphorically to refer to the lubricant that keeps the vehicle's electric motor and other components running smoothly. While EVs don't use traditional engine oil like internal combustion engines, they do require specialized lubricants and cooling systems to maintain optimal performance. These lubricants help reduce friction, prevent overheating, and ensure the longevity of the electric motor and other mechanical parts.

Electric vehicles operate on electric motors powered by batteries, eliminating the need for gasoline or diesel fuel. As a result, they don't require traditional engine oil to lubricate the engine's moving parts. Instead, EVs use a combination of lubricants, including motor oil for the electric motor, transmission fluid, and cooling fluids to maintain the system's efficiency and prevent wear.

In an electric vehicle, several critical components need proper lubrication to function optimally. These include the electric motor, inverter, transmission (if equipped), and the drivetrain. Each of these components has specific lubrication requirements to ensure smooth operation, reduce friction, and prevent damage from heat and mechanical stress.

The maintenance needs of electric vehicles can vary depending on the make and model, as well as driving conditions. Generally, EVs require less frequent maintenance compared to traditional cars due to their simpler mechanical systems. However, regular checks and lubrication of the electric motor, inverter, and other components are still essential. It is recommended to follow the manufacturer's guidelines for maintenance schedules and lubrication intervals to ensure the vehicle's longevity.

Yes, several specialized lubricants and oils are designed for electric vehicles. These include synthetic motor oils formulated for electric motors, which offer excellent low-temperature protection and high-temperature stability. Additionally, EV-specific lubricants for the inverter, transmission, and drivetrain are available to ensure optimal performance and longevity in these critical components. It's important to use the recommended lubricants as specified by the vehicle manufacturer.