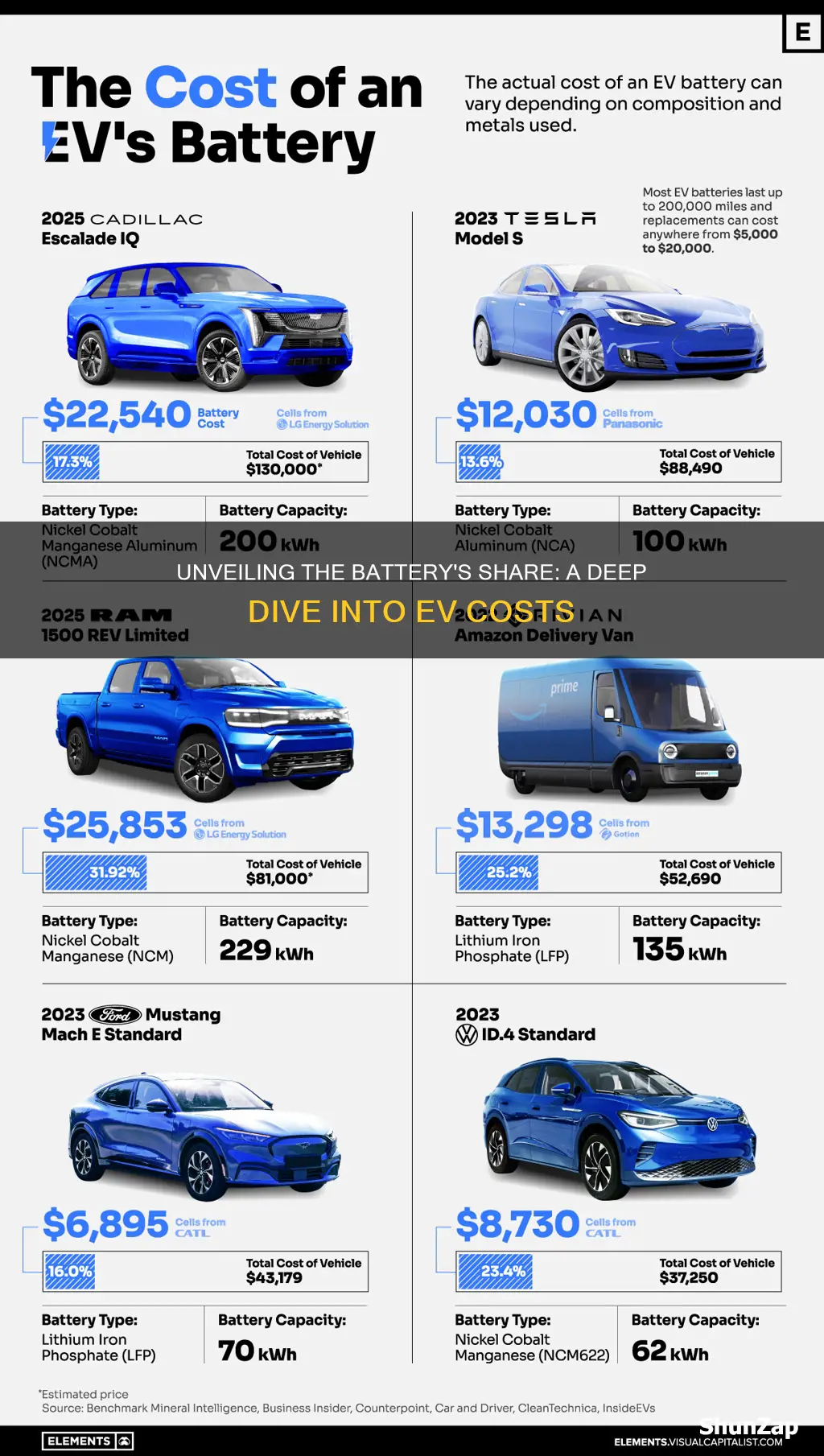

The cost of electric vehicles (EVs) is a significant consideration for consumers, and one of the most substantial expenses is the battery pack. The battery is a critical component of an EV, storing the energy required to power the vehicle and, in some cases, even the entire driving range. The percentage of the total cost that the battery represents varies widely depending on the vehicle, its range, and the technology used. Understanding this breakdown can help consumers make informed decisions when purchasing an electric vehicle, as it directly impacts the overall affordability and value proposition of the car.

What You'll Learn

- Battery Cost Breakdown: A detailed analysis of battery costs in electric vehicles

- Battery Efficiency: How battery technology impacts overall vehicle efficiency and performance

- Battery Recycling: The environmental impact and economic benefits of recycling EV batteries

- Battery Price Trends: Historical and projected changes in battery prices over time

- Battery Cost Optimization: Strategies to reduce battery costs in EV manufacturing

Battery Cost Breakdown: A detailed analysis of battery costs in electric vehicles

The battery is a critical component of electric vehicles (EVs), and its cost is a significant factor in determining the overall price of these vehicles. The percentage of the total cost of an EV that is attributed to the battery can vary widely, depending on several factors, including the vehicle's size, range, and intended use.

On average, batteries account for approximately 30-40% of the total cost of an electric vehicle. This percentage is expected to decrease as technology advances and production scales up, making EVs more affordable. For instance, the cost of lithium-ion batteries, the most common type used in EVs, has been steadily declining over the years due to increased production and improved manufacturing processes.

The breakdown of battery costs in EVs can be analyzed from several angles. Firstly, the cost of the battery pack itself, which includes the cells, modules, and associated electronics, can vary based on the vehicle's specifications. For instance, a high-performance EV with a longer range will typically have a more expensive battery pack compared to a standard city car. The number of cells in the pack also plays a role; a higher cell count generally leads to a higher cost.

Secondly, the cost of the battery system, which includes the pack, the thermal management system, and the battery management system (BMS), adds to the overall expense. The BMS is crucial for monitoring and controlling the battery's performance, ensuring it operates within safe parameters. This system's complexity and the quality of its components can influence the overall cost.

Lastly, the cost of the battery supply chain, including raw material sourcing, manufacturing, and distribution, is a significant portion of the total battery cost. Lithium, cobalt, and nickel are among the critical raw materials, and their prices can fluctuate based on market dynamics and supply chain logistics. As the demand for EVs grows, the focus on sustainable and ethical sourcing of these materials will become increasingly important.

In summary, the battery is a substantial contributor to the cost of electric vehicles, but this percentage is subject to change as technology evolves and production methods improve. Understanding the breakdown of battery costs is essential for both consumers and manufacturers in the EV market, as it influences purchasing decisions and the development of more cost-effective and sustainable vehicles.

Electric Vehicle Mileage Tax: Fair or Unfair for Drivers?

You may want to see also

Battery Efficiency: How battery technology impacts overall vehicle efficiency and performance

The battery is a critical component of electric vehicles (EVs), and its efficiency plays a pivotal role in determining the overall performance and efficiency of the vehicle. The cost of batteries is a significant factor in the overall expense of EVs, and understanding their impact is essential for both manufacturers and consumers.

Battery technology has advanced significantly, and modern EV batteries are more efficient than ever before. The efficiency of a battery is measured by its ability to store and deliver energy effectively. Higher efficiency means that more of the energy supplied to the battery is converted into useful power for the vehicle, resulting in improved performance and range. For instance, advanced lithium-ion batteries, which are commonly used in EVs, have achieved energy densities that allow for longer driving ranges between charges. This is a direct outcome of technological improvements in battery chemistry and design.

The impact of battery efficiency on vehicle performance is twofold. Firstly, efficient batteries contribute to a higher power-to-weight ratio, enabling EVs to accelerate more quickly and respond promptly to driver inputs. This is particularly important for electric sports cars and high-performance EVs, where rapid acceleration and responsive handling are desirable. Secondly, efficient batteries result in better energy management, allowing for more precise control over the vehicle's power output and, consequently, improved fuel economy or, in this case, energy efficiency. This is especially beneficial for long-distance travel, where optimizing energy usage can significantly extend the vehicle's range.

In addition to performance, battery efficiency also influences the overall cost-effectiveness of EVs. As mentioned earlier, batteries are a substantial portion of the vehicle's cost. By improving efficiency, manufacturers can reduce the amount of battery capacity required to achieve a desired range, thereby lowering the overall cost. This is particularly relevant for mass-market EVs, where cost-efficiency is a critical factor in making electric mobility accessible to a broader audience.

Furthermore, the efficiency of battery technology is closely tied to its environmental impact. More efficient batteries can store and deliver energy with reduced losses, which translates to lower energy consumption during vehicle operation. This not only contributes to a reduced carbon footprint but also aligns with the goal of making EVs more sustainable and environmentally friendly. As the world moves towards greener transportation, battery efficiency will continue to be a key area of focus for researchers and engineers.

In summary, battery efficiency is a critical aspect of electric vehicle technology, influencing both performance and cost-effectiveness. The continuous development of battery technology aims to enhance energy storage and delivery, resulting in improved vehicle efficiency and a more sustainable future for transportation. Understanding these impacts is essential for the widespread adoption of electric vehicles and the realization of their full potential.

The Electric Car Leader: Who's Topping the EV Race?

You may want to see also

Battery Recycling: The environmental impact and economic benefits of recycling EV batteries

The growing popularity of electric vehicles (EVs) has led to an increased focus on the environmental and economic aspects of their battery systems. As EVs gain traction, the question of what happens to their batteries at the end of their lifespan becomes crucial. Battery recycling is an essential process that addresses the environmental impact and offers significant economic benefits.

From an environmental perspective, recycling EV batteries is crucial to minimizing the ecological footprint of the automotive industry. Electric vehicle batteries contain valuable and potentially hazardous materials, including lithium, cobalt, and nickel. When these batteries are not properly recycled, they can lead to soil and water contamination, posing risks to ecosystems and human health. By implementing recycling processes, we can prevent these harmful substances from entering the environment. The recycling process involves carefully extracting and processing these materials, ensuring they are reused or disposed of safely and responsibly.

The economic advantages of battery recycling are substantial. Firstly, it reduces the need for extracting and processing raw materials, which can be energy-intensive and environmentally damaging. By reusing the materials from recycled batteries, manufacturers can decrease their reliance on virgin resources, leading to cost savings and a more sustainable supply chain. Additionally, the recycling industry creates job opportunities, especially in the growing field of sustainable technology. As the demand for EV batteries increases, so does the need for skilled workers in battery recycling facilities, contributing to local economies and employment.

Furthermore, the recycling process can extend the lifespan of certain battery components, allowing for their reuse in various applications. For instance, recycled lithium-ion batteries can be refurbished and utilized in energy storage systems or even as backup power sources. This not only reduces waste but also provides an affordable and sustainable solution for energy storage, which is crucial for the integration of renewable energy sources into the grid.

In summary, battery recycling plays a vital role in mitigating the environmental impact of EV batteries while offering significant economic advantages. It ensures the responsible handling of valuable and potentially hazardous materials, reduces the demand for raw resources, and creates new job opportunities. As the world embraces the transition to electric mobility, implementing efficient recycling practices will be essential to building a sustainable and circular economy.

The Electric Revolution: Unlocking the Percentage of New Electric Vehicles

You may want to see also

Battery Price Trends: Historical and projected changes in battery prices over time

The cost of batteries has been a significant factor in the development and adoption of electric vehicles (EVs). Over the years, there has been a noticeable trend in battery prices, which has influenced the overall cost structure of EVs. Historically, batteries have been a substantial portion of the total cost of electric vehicles, often accounting for a significant percentage. This is primarily due to the advanced technology and materials required to build high-capacity, efficient batteries.

In the early days of EVs, battery prices were relatively high, making up a large proportion of the vehicle's total cost. For instance, in the late 1990s and early 2000s, the cost of lithium-ion batteries, which are commonly used in EVs, was a major contributor to the high price tags of electric cars. This era saw the introduction of the first-generation EVs, and the limited production volumes and research efforts led to higher battery costs.

However, as the market for EVs grew and technological advancements accelerated, battery prices began to decrease. The economies of scale in battery production played a crucial role in reducing costs. With the increasing demand for electric vehicles, manufacturers started producing batteries in larger quantities, driving down the average cost per unit. Additionally, improvements in battery technology, such as more efficient cathode and anode materials, contributed to lower production costs.

The historical data reveals a steady decline in battery prices, with some years showing more significant drops than others. For example, the period between 2010 and 2015 witnessed a substantial reduction in battery costs, primarily due to increased investment in battery research and development, as well as the establishment of large-scale battery manufacturing facilities. This trend has continued, and recent reports indicate that battery prices have continued to fall, making EVs more affordable for consumers.

Looking ahead, projections suggest that battery prices will continue to decrease, although the rate of decline may slow down. The future of battery technology is focused on further improvements in energy density, charging speed, and longevity, all while keeping costs competitive. As a result, the percentage of the EV's cost attributed to batteries is expected to decrease, but it will still remain a significant component. The ongoing research and development efforts aim to make EVs more accessible and cost-effective, driving the market towards a more sustainable and environmentally friendly transportation solution.

Unraveling the Mystery: Hairball Phenomenon in Electric Vehicles

You may want to see also

Battery Cost Optimization: Strategies to reduce battery costs in EV manufacturing

The battery is a significant component of the overall cost structure of electric vehicles (EVs), often accounting for a substantial portion of the vehicle's price. According to various studies, batteries can represent anywhere between 30% to 50% of the total manufacturing cost of an EV. This high cost is primarily due to the expensive raw materials, complex manufacturing processes, and the large-scale production requirements of batteries. However, as the demand for EVs continues to rise, there is an urgent need to optimize battery costs to make electric mobility more affordable and accessible to a wider population.

One of the primary strategies to reduce battery costs is to focus on material science and chemistry. Researchers and engineers are constantly exploring new materials and formulations that can offer higher energy density, improved safety, and reduced manufacturing costs. For instance, the development of lithium-ion batteries with higher nickel content has shown promise in increasing energy density while also driving down costs. Solid-state batteries, which replace the liquid electrolyte with a solid conductive material, are another area of interest as they could offer higher energy density and potentially lower costs compared to traditional lithium-ion batteries.

Process optimization and manufacturing efficiency are also key areas for cost reduction. The current manufacturing process for batteries is energy-intensive and involves multiple complex steps. Automating these processes and implementing lean manufacturing techniques can significantly reduce labor costs and improve overall efficiency. Additionally, the development of in-house battery production facilities by EV manufacturers can help streamline the supply chain, reduce transportation costs, and ensure a consistent supply of high-quality batteries.

Another approach to battery cost optimization is the implementation of recycling and second-life programs. As the number of EVs on the road increases, so does the number of batteries that will need to be replaced or retired. Recycling these batteries can recover valuable materials, reduce waste, and lower the overall cost of battery production. Second-life applications, where retired batteries are repurposed for less demanding energy storage needs, can also extend the useful life of batteries and provide a cost-effective solution for energy storage.

Finally, government incentives and subsidies play a crucial role in encouraging investment in battery technology and infrastructure. Tax credits, grants, and other financial incentives can help EV manufacturers and battery producers drive down costs by investing in research and development, adopting new technologies, and scaling up production. These incentives can also stimulate competition, leading to innovation and cost reductions across the industry.

Colorado's Electric Vehicle Revolution: A Green Shift in Sales

You may want to see also

Frequently asked questions

The cost of batteries is a significant component of the overall price of electric vehicles. On average, batteries can account for around 30-40% of the total cost of an EV. This percentage can vary depending on the vehicle's size, range, and specific battery technology used.

Yes, several factors contribute to the cost of batteries in electric vehicles. These include the type of battery chemistry (e.g., lithium-ion), the energy density, the number of cells, the vehicle's range, and the overall design. Additionally, market demand, production volume, and technological advancements can also impact battery prices.

The cost of batteries for electric vehicles has decreased significantly over the years due to technological improvements and economies of scale. In the early days of EVs, batteries were a substantial portion of the vehicle's total cost. However, with advancements in technology and increased production, the cost has become more competitive, allowing for a wider range of EV models at various price points.