American-made electric vehicles (EVs) often come with a higher price tag compared to their counterparts in other countries. This disparity can be attributed to various factors, including the cost of raw materials, manufacturing processes, and the overall market dynamics. While the United States has been a leader in EV technology and innovation, the higher prices can be a barrier for many consumers, especially when compared to countries like China and Norway, which have implemented incentives to promote EV adoption. This comparison highlights the complex interplay between production costs, government policies, and consumer preferences in the global EV market.

| Characteristics | Values |

|---|---|

| Country Comparison | American-made electric vehicles tend to be more expensive compared to their counterparts in other countries, especially in regions with strong EV markets like Europe and China. |

| Price Differences | Studies show that EVs in the US can be 10-20% more expensive due to factors like higher production costs, different tax incentives, and varying market demands. |

| Market Dynamics | The US market for EVs is relatively smaller, which can influence pricing strategies and contribute to higher costs. |

| Tax and Incentives | Some countries offer substantial tax breaks and subsidies for EV purchases, making them more affordable for consumers. |

| Supply and Demand | The global demand for EVs is increasing, and regions with higher demand might negotiate better prices from manufacturers. |

| Production Costs | Labor, raw materials, and component costs can vary across countries, impacting the final price of electric vehicles. |

| Brand and Model Variations | Price differences can also be attributed to specific brand strategies, model features, and performance variations. |

What You'll Learn

- Market Dynamics: Price differences due to market competition and demand variations

- Production Costs: Labor, materials, and manufacturing expenses impact vehicle pricing

- Tax and Incentives: Government policies and subsidies affect the final cost

- Import/Export Duties: Tariffs and trade regulations contribute to price disparities

- Supply Chain: Local vs. global supply chains influence production and pricing

Market Dynamics: Price differences due to market competition and demand variations

The pricing of electric vehicles (EVs) in the United States and other countries can be influenced by various market dynamics, particularly the interplay of competition and demand. In the US market, the presence of a few dominant EV manufacturers has led to a competitive landscape that drives prices down. These companies, such as Tesla, have disrupted the automotive industry by offering innovative, high-performance EVs at competitive prices, often undercutting traditional internal combustion engine (ICE) vehicles. As a result, consumers in the US benefit from a wide range of choices, with prices varying based on factors like brand, model, and features. This competitive environment encourages manufacturers to continuously improve their offerings, reduce costs, and maintain price competitiveness.

In contrast, other countries may experience different market dynamics that impact EV pricing. For instance, in regions with a smaller EV market, there might be fewer competitors, which can lead to higher prices. This is often due to the economies of scale; with lower production volumes, manufacturers may have less incentive to drive down costs, and the limited competition can result in higher prices to cover production expenses and maintain profitability. Additionally, demand variations across regions play a significant role. In some countries, government incentives and subsidies for EV adoption can stimulate demand, leading to increased sales and potentially lower prices due to higher production volumes.

Market competition is a critical factor in price determination. In highly competitive markets, such as those in Europe and Asia, multiple EV manufacturers compete for market share. This competition often results in aggressive pricing strategies, with companies offering discounts, loyalty programs, and financing options to attract customers. As a consequence, consumers in these regions may find better deals and more affordable EVs compared to the US. However, it's important to note that the level of competition can vary within a country, with certain regions or cities experiencing more intense competition due to market saturation or the presence of specific consumer preferences.

Demand variations also contribute to price differences. In regions with a high demand for EVs, manufacturers might be able to charge a premium due to limited supply or specific consumer preferences. For example, in coastal cities with a strong environmental focus, consumers might be willing to pay more for eco-friendly vehicles, leading to higher prices. Conversely, in areas with lower demand, manufacturers may offer discounts or incentives to stimulate sales, making EVs more affordable. Understanding these demand patterns is crucial for both consumers and manufacturers, as it helps predict price trends and make informed decisions.

In summary, market competition and demand variations significantly impact the pricing of American-made EVs in comparison to other countries. Competitive markets with multiple players tend to offer more affordable options, while regions with fewer competitors or lower demand may result in higher prices. Consumers should consider these market dynamics when purchasing EVs, as they can influence the overall cost and availability of these vehicles. Additionally, manufacturers need to carefully analyze these factors to develop effective pricing strategies and ensure their products remain competitive in the global EV market.

Solar Power on the Go: Why EVs Don't Catch the Sun's Energy

You may want to see also

Production Costs: Labor, materials, and manufacturing expenses impact vehicle pricing

The production costs of electric vehicles (EVs) in the United States can indeed be higher compared to other countries, and this is primarily due to the factors of labor, materials, and manufacturing expenses. These elements significantly influence the overall pricing of American-made EVs, making them potentially more expensive on the global market.

Labor costs are a significant contributor to the higher price tags of American EVs. The United States has a higher minimum wage compared to some other countries, especially when considering the skilled labor required for EV assembly. Electric vehicle manufacturing involves intricate processes, including battery production, motor assembly, and software integration, which demand a well-trained workforce. As a result, the wages for workers in the US EV industry are often higher, leading to increased production expenses.

Materials and component sourcing also play a crucial role in the pricing of EVs. The United States may not have the same level of local material availability as some other countries, which can drive up costs. For instance, rare earth metals and lithium, essential for battery production, are often sourced from international markets. The transportation and processing of these materials can be expensive, adding to the overall production cost. Additionally, the US might face higher tariffs or import duties on certain components, further impacting the final vehicle price.

Manufacturing expenses in the US EV industry are another critical factor. The infrastructure and equipment required for EV production are typically more advanced and specialized compared to traditional internal combustion engine (ICE) vehicles. This includes advanced robotics, automated assembly lines, and specialized testing equipment. Upgrading and maintaining such infrastructure can be costly, and these expenses are often reflected in the vehicle's final price. Moreover, the US market's demand for EVs might not yet be as high as in other regions, which could influence production volumes and, consequently, the per-unit production costs.

In summary, the higher production costs of American-made EVs can be attributed to the combination of labor, materials, and manufacturing expenses. These factors collectively contribute to the vehicle's final price, making American EVs potentially more expensive in international markets. Understanding these production cost dynamics is essential for consumers, policymakers, and manufacturers alike, as it highlights the challenges and opportunities in the global EV market.

Arizona's Electric Revolution: Unveiling the EV Leaders

You may want to see also

Tax and Incentives: Government policies and subsidies affect the final cost

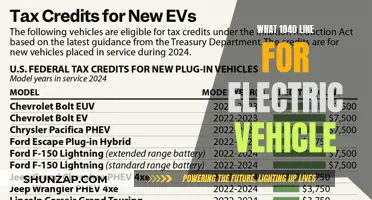

The cost of electric vehicles (EVs) in the United States can be influenced by various factors, including tax policies and government incentives, which often vary across different countries. When it comes to the final price consumers pay for American-made EVs, these government interventions play a significant role.

In the US, the federal government has implemented several tax credits and incentives to promote the adoption of electric vehicles. One of the most notable is the Tax Credit for Electric Vehicles, which provides a substantial tax credit to consumers purchasing or leasing new electric cars. This credit can significantly reduce the upfront cost of EVs, making them more affordable for American buyers. For instance, the credit can cover up to 30% of the vehicle's sale price, which is a substantial amount, especially for high-end electric cars. This incentive is designed to encourage consumers to choose electric over traditional internal combustion engine (ICE) vehicles, thus reducing the environmental impact of the transportation sector.

Additionally, state governments in the US have also introduced their own incentives and tax benefits to further lower the cost of EVs. Some states offer rebates or direct cash incentives to residents purchasing electric vehicles, which can vary in amount and eligibility criteria. These state-level policies often complement the federal tax credit, providing a more comprehensive financial boost to consumers. For example, California, known for its aggressive environmental policies, offers a Clean Vehicle Rebate Project that provides significant financial assistance to residents buying or leasing new electric cars, making EVs more accessible and affordable in the state.

On the other hand, in countries like Norway, the government takes a different approach by waiving certain taxes and duties on electric vehicles, making them significantly cheaper to purchase. Norway's zero-emission car strategy includes a full exemption from the country's high value-added tax (VAT) on EVs, which can be a substantial saving for consumers. This strategy has led to a high adoption rate of electric vehicles in Norway, with a significant portion of the market being occupied by EVs.

The contrast in tax and incentive policies between the US and countries like Norway highlights how government interventions can impact the cost and popularity of electric vehicles. In the US, while federal and state-level incentives provide financial benefits, the overall cost of EVs might still be higher compared to countries with more aggressive EV-friendly policies. This is because the absence of certain tax benefits and the varying levels of incentives can result in different price points for the same EV model across different markets.

In summary, tax and incentives are critical factors in determining the final cost of American-made electric vehicles in the global market. The US's approach to promoting EVs through tax credits and state-level incentives can make EVs more affordable, but it may not always result in the lowest prices compared to countries with more comprehensive and favorable policies. Understanding these government interventions is essential for consumers and policymakers alike to navigate the EV market effectively.

Unlocking California's EV Tax Credit: When You Get It

You may want to see also

Import/Export Duties: Tariffs and trade regulations contribute to price disparities

The cost of electric vehicles (EVs) in different countries can be influenced by various factors, including import/export duties and trade regulations. These factors often play a significant role in shaping the final price that consumers pay for American-made EVs in international markets. One of the primary reasons for price disparities is the application of tariffs and taxes on imported goods.

When American EV manufacturers export their vehicles to other countries, they may face import duties imposed by the importing nation. These tariffs are typically calculated as a percentage of the vehicle's value and can significantly impact the overall cost. For instance, if a country imposes a 10% tariff on imported EVs, the price of American-made cars in that market will be higher compared to countries without such tariffs. This additional cost is often passed on to consumers, making American EVs more expensive in certain regions.

Trade regulations and policies also contribute to price variations. Different countries have varying standards and requirements for vehicle safety, emissions, and certification. American EVs might need to undergo additional testing and comply with specific regulations to meet these standards, incurring extra costs. These regulatory compliance expenses can be reflected in the final price, making American-made EVs more costly in markets with stringent regulations.

Furthermore, the complexity of international trade logistics can influence pricing. Exporting vehicles internationally involves various costs, such as documentation, shipping, and insurance. These expenses are often higher for specialized vehicles like EVs, which may require additional handling and customization. As a result, the overall cost of American-made EVs in international markets can be higher due to these logistical considerations.

In summary, import/export duties, tariffs, and trade regulations significantly impact the pricing of American-made electric vehicles in different countries. These factors contribute to the observed price disparities, making EVs from the United States potentially more expensive in certain international markets. Understanding these trade-related costs is essential for both manufacturers and consumers to navigate the global EV market effectively.

Electric Vehicle Fire Incidents: A Growing Concern

You may want to see also

Supply Chain: Local vs. global supply chains influence production and pricing

The automotive industry is a complex global network, and the supply chain plays a pivotal role in determining the cost and availability of electric vehicles (EVs). When considering the pricing of American-made EVs, the comparison between local and global supply chains becomes a critical factor.

Local supply chains, often referred to as domestic or regional sourcing, have several advantages. Firstly, they reduce transportation costs and lead times, as components can be sourced from nearby suppliers. This proximity can result in more efficient production processes, allowing manufacturers to optimize inventory management and reduce waste. For instance, if an American EV manufacturer sources batteries and motors from local suppliers, it can streamline the assembly line, ensuring a steady supply of components and potentially reducing production costs. Additionally, local supply chains can foster stronger relationships with suppliers, leading to better negotiation power and potentially lower procurement costs.

However, local supply chains may also present challenges. The availability of specialized components or raw materials might be limited, especially for niche products like EVs. This could result in longer production lead times or even temporary production halts if a critical component is not readily available. Furthermore, local suppliers might not have the same scale of production as their global counterparts, which could impact the overall cost structure, especially for high-volume production.

On the other hand, global supply chains offer a different set of advantages and considerations. By accessing a wider network of suppliers and manufacturers worldwide, EV producers can benefit from economies of scale. Global suppliers often have the capacity to produce components in larger volumes, which can drive down production costs per unit. For example, if an American EV company sources batteries from a global manufacturer with a high production capacity, it can negotiate better prices and secure a consistent supply of high-quality batteries. This can lead to more competitive pricing for the final product.

The global supply chain also provides access to a diverse range of technologies and expertise. Different countries and regions have specialized in specific automotive components, allowing manufacturers to tap into these strengths. For instance, some countries might excel in producing advanced battery technology, while others might focus on efficient motor design. By incorporating these global specializations into their supply chain, EV producers can enhance the performance and features of their vehicles.

In conclusion, the choice between local and global supply chains for American-made EVs has significant implications for production and pricing. Local supply chains offer benefits in terms of reduced transportation costs and potential supplier relationships, but may face challenges related to component availability and scale. Global supply chains provide access to economies of scale, diverse technologies, and specialized expertise, which can result in more competitive pricing. The optimal strategy might involve a combination of both approaches, carefully considering the specific needs and goals of the EV manufacturer.

The Future of Transportation: When Electric Vehicles Are a Must

You may want to see also

Frequently asked questions

The cost of electric vehicles (EVs) can vary significantly depending on various factors, including the country of origin, market demand, production volumes, and local incentives. While it is true that some American-made EVs might have a higher price tag initially, this is not always the case. The cost can be influenced by factors like research and development expenses, brand reputation, and the specific features and technologies offered. Many American EV manufacturers have been working on making their products more affordable and competitive in the market.

Price variations in EVs can be attributed to several factors. Firstly, the cost of raw materials and components can differ across countries due to market dynamics and supply chain logistics. Secondly, government incentives and subsidies play a crucial role in making EVs more affordable for consumers. Some countries offer tax credits, rebates, or other financial incentives to promote EV adoption, which can directly impact the final price. Additionally, production scale and economies of scale can influence costs; larger production volumes often lead to lower per-unit costs.

Resale value is an essential consideration for many car buyers, and it can vary between American and international EV brands. American EV manufacturers have been focusing on building a strong resale market for their vehicles, which can be influenced by factors like brand loyalty, warranty programs, and the overall demand for used EVs. However, it's important to note that resale values are also dependent on factors such as vehicle condition, mileage, and market trends. Some international brands with a strong presence in the US market might also offer competitive resale values, especially if they have established a solid reputation and customer base.

American EV manufacturers are adopting various strategies to enhance cost-competitiveness. These include optimizing production processes, increasing production volumes to benefit from economies of scale, and negotiating better deals for raw materials and components. Additionally, some companies are exploring partnerships and collaborations to share resources and expertise, which can help reduce costs. Government support and incentives can also play a significant role in making American EVs more affordable, especially when compared to regions with fewer or no such incentives.