Electric vehicle (EV) batteries have become a crucial component in the automotive industry, driving the transition towards sustainable transportation. As the demand for EVs continues to rise, understanding the cost of these batteries is essential for both consumers and manufacturers. The price of an EV battery can vary significantly depending on several factors, including the type of battery, its capacity, the vehicle's make and model, and the overall market trends. This article aims to explore the various factors influencing EV battery costs and provide insights into the current pricing landscape, helping consumers make informed decisions when considering an electric vehicle purchase.

What You'll Learn

- Battery Chemistry: Understanding the cost variations of different battery chemistries

- Capacity and Range: How battery capacity affects vehicle range and price

- Production Costs: Manufacturing expenses of EV batteries and their impact on pricing

- Recycling and Sustainability: The economic benefits of recycling EV batteries

- Market Trends: Fluctuations in battery prices and their influence on the EV market

Battery Chemistry: Understanding the cost variations of different battery chemistries

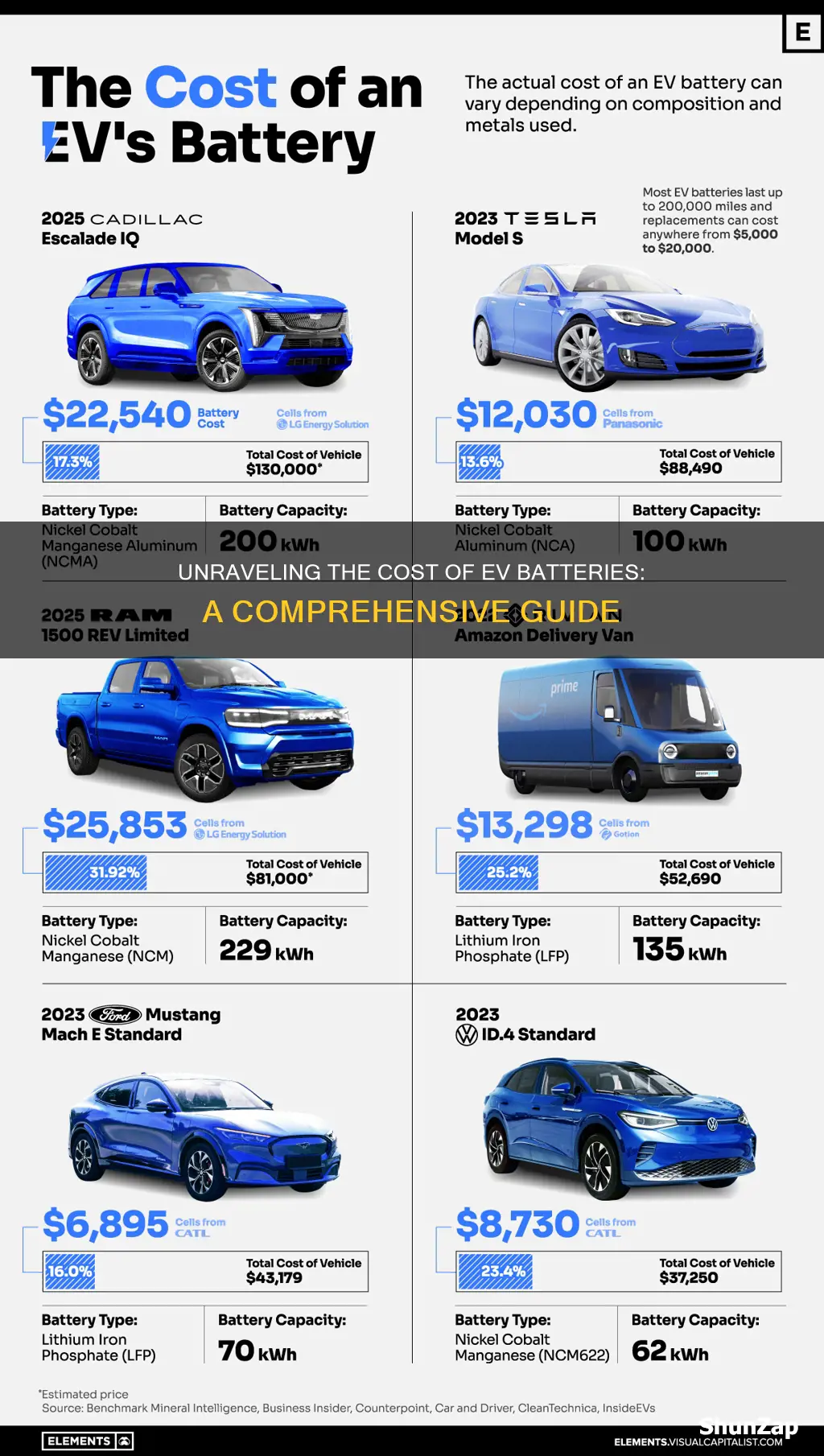

Battery chemistry plays a pivotal role in determining the cost of electric vehicle (EV) batteries. Different chemistries offer unique advantages and disadvantages, impacting the overall price. For instance, lithium-ion batteries, the most common type in EVs, utilize lithium cobalt oxide (LCO) or lithium iron phosphate (LFP) cathodes. LCO, known for its high energy density, is more expensive due to the scarcity and cost of cobalt. In contrast, LFP offers a lower cost and longer cycle life but with slightly lower energy density. This variation in chemistry directly influences the battery's price, with LCO-based batteries generally being more expensive than LFP-based ones.

Another critical factor is the anode material. Graphite, a common anode material in lithium-ion batteries, is relatively inexpensive and offers good performance. However, silicon-based anodes, which can store more lithium and enhance battery capacity, are more expensive due to their higher production complexity and potential for degradation over time. The choice of anode material, therefore, significantly impacts the battery's cost and performance characteristics.

Beyond the chemistry, the manufacturing process also contributes to cost variations. Large-scale production can drive down costs, as economies of scale allow for more efficient processes and material usage. Additionally, the use of advanced manufacturing techniques, such as roll-to-roll processing for battery components, can reduce costs by streamlining production and minimizing waste.

Furthermore, the overall battery design and architecture can influence costs. For instance, a battery with a higher energy density, achieved through advanced cell design, may be more expensive to produce but can result in a smaller, lighter battery pack, potentially reducing the overall vehicle weight and improving efficiency. Conversely, a battery with a lower energy density might be more cost-effective but would require a larger pack, increasing the vehicle's size and weight.

In summary, the cost of EV batteries is intricately linked to battery chemistry, with different chemistries offering varying performance and cost profiles. The choice of cathode and anode materials, manufacturing processes, and overall battery design all contribute to the final price. As technology advances and production scales, we can expect to see further improvements in battery chemistry and manufacturing, potentially reducing the cost of EV batteries and making electric vehicles more accessible to a broader market.

Unveiling the Secrets: A Guide to Spotting Electric Vehicles

You may want to see also

Capacity and Range: How battery capacity affects vehicle range and price

The capacity of an electric vehicle (EV) battery is a critical factor that directly influences the range a vehicle can achieve on a single charge. Battery capacity is measured in kilowatt-hours (kWh), and it represents the amount of energy the battery can store. A higher kWh rating generally means a larger battery pack, which can store more energy and, consequently, provide a longer driving range. For instance, a 100 kWh battery will offer a more extended range compared to a 50 kWh battery, assuming all other factors are equal.

The relationship between battery capacity and vehicle range is straightforward: more capacity leads to more range. This is because a larger battery can store more energy, allowing the vehicle to travel farther before needing a recharge. However, it's important to note that increasing battery capacity also increases the vehicle's weight and cost. Larger batteries are heavier, which can negatively impact the vehicle's performance and efficiency.

The impact of battery capacity on price is significant. Higher kWh batteries are more expensive to manufacture and purchase. This is due to the use of advanced materials and the complexity of the battery design. As a result, vehicles with larger batteries tend to be more expensive upfront. For example, a luxury EV with a 100 kWh battery might cost several thousand dollars more than a similar model with a 50 kWh battery.

Despite the higher cost, some EV owners prioritize range and are willing to invest in larger batteries. These vehicles often cater to specific market segments, such as long-distance travelers or those in regions with limited charging infrastructure. The trade-off is that these vehicles may have a higher purchase price but offer the convenience of extended range, reducing the need for frequent charging stops during long journeys.

In summary, battery capacity plays a pivotal role in determining the range and price of electric vehicles. While larger batteries provide more range, they also come with a higher price tag due to increased manufacturing costs and vehicle weight. Consumers must consider their specific needs, balancing range requirements with budget constraints to make an informed decision when purchasing an EV.

Uncover the Federal EV Tax Credit: A Green Car Incentive

You may want to see also

Production Costs: Manufacturing expenses of EV batteries and their impact on pricing

The cost of electric vehicle (EV) batteries is a critical factor in determining the overall price of EVs. The manufacturing process of these batteries involves multiple stages, each contributing to the final cost. One of the primary expenses is the acquisition of raw materials, primarily lithium, cobalt, and nickel, which are essential for the cathode and anode production. The prices of these materials have been volatile, impacting the overall battery cost. For instance, lithium prices have seen significant fluctuations due to supply chain issues and increasing demand, directly affecting the manufacturing expenses.

Battery manufacturing facilities require substantial investment in specialized equipment and technology. The production process involves complex chemical reactions and precise engineering, demanding high-tech machinery and skilled labor. Setting up such facilities is expensive, and the cost is often passed on to consumers. Additionally, the energy consumption during battery production is substantial, leading to higher operational costs for manufacturers.

Another significant aspect is the labor cost associated with battery assembly and quality control. Skilled workers are needed to handle the intricate processes, ensuring the batteries meet the required standards. The labor-intensive nature of battery manufacturing contributes to a substantial portion of the overall production cost. Furthermore, the recycling and disposal of used batteries also incur expenses, as these processes are essential for sustainability and environmental compliance.

The impact of these production costs on EV battery pricing is significant. Manufacturers often aim to balance their expenses with competitive pricing to attract customers. However, the high costs of raw materials, manufacturing, and labor can lead to higher battery prices, which, in turn, affect the overall EV price. As a result, consumers may face a trade-off between the benefits of electric mobility and the financial burden of battery costs.

In summary, the manufacturing expenses of EV batteries are a complex interplay of raw material costs, production facility investments, labor, and energy consumption. These factors collectively influence the final price of EV batteries, which has a direct impact on the overall affordability and competitiveness of electric vehicles in the market. Understanding these production costs is essential for consumers, manufacturers, and policymakers to make informed decisions regarding the adoption and development of electric vehicle technologies.

The Lithium Conundrum: Can We Keep Up with EV Demand?

You may want to see also

Recycling and Sustainability: The economic benefits of recycling EV batteries

The growing popularity of electric vehicles (EVs) has led to a surge in demand for lithium-ion batteries, which are the power source for these vehicles. As a result, the question of battery cost has become increasingly relevant, especially when considering the long-term economic implications of EV ownership. While the initial purchase price of an EV battery can be a significant investment, the economic benefits of recycling these batteries are substantial and often overlooked.

Recycling EV batteries is an essential aspect of sustainability and has the potential to create a closed-loop system for battery production and disposal. The process involves recovering valuable materials such as lithium, cobalt, and nickel from used batteries, which can then be reused in new battery manufacturing. This not only reduces the need for mining and extracting raw materials but also minimizes the environmental impact associated with these processes. By extending the lifespan of batteries through recycling, we can significantly reduce the overall cost of EV ownership.

The economic advantages of recycling EV batteries are twofold. Firstly, it provides a steady supply of raw materials for battery manufacturers, ensuring a more stable and potentially lower-cost production process. This is particularly important as the demand for EVs continues to rise, and the industry aims to meet the growing need without compromising on sustainability. Secondly, recycling creates jobs and stimulates the development of a circular economy. Collecting, processing, and reusing batteries require specialized labor, creating employment opportunities in the recycling sector.

Furthermore, the recycling process can generate significant revenue. Used EV batteries, even after their performance has declined, still retain a substantial amount of usable materials. These materials can be sold to manufacturers at a profit, providing an incentive for battery recycling. As the EV market expands, the volume of recyclable batteries will increase, creating a more robust and profitable recycling industry. This economic benefit can contribute to the overall affordability of EVs, making them more accessible to a wider range of consumers.

In summary, the economic benefits of recycling EV batteries are far-reaching. It promotes sustainability by reducing the environmental impact of battery production and disposal, while also creating a more efficient and cost-effective system. The recycling industry can thrive, providing jobs and revenue, and ultimately contributing to the long-term viability of the EV market. As the world moves towards a greener future, embracing the recycling of EV batteries is a crucial step in ensuring a sustainable and economically sound transportation system.

Boosting EV Adoption: Creative Incentives for a Greener Future

You may want to see also

Market Trends: Fluctuations in battery prices and their influence on the EV market

The cost of batteries for electric vehicles (EVs) has been a significant factor in the market's growth and development. Over the past decade, battery prices have experienced notable fluctuations, which have had a profound impact on the overall EV market. These price variations are primarily driven by several key factors, including technological advancements, supply chain dynamics, and government incentives.

One of the most significant trends in recent years is the steady decrease in battery prices. This is largely due to technological improvements in battery chemistry and manufacturing processes. For instance, lithium-ion batteries, which are commonly used in EVs, have seen a reduction in cost per kilowatt-hour (kWh) due to increased production efficiency and the development of more advanced materials. As a result, EVs have become more affordable for consumers, making them a more attractive option compared to traditional internal combustion engine vehicles. This trend has accelerated the adoption of electric vehicles, especially in regions with supportive government policies and incentives.

However, the market has also witnessed periods of higher battery prices, which can be attributed to various factors. One such factor is the global supply chain disruptions, which have affected the availability and cost of raw materials like lithium, cobalt, and nickel. These materials are crucial components in battery production, and any shortage or price hike in these commodities can directly impact battery costs. Additionally, geopolitical tensions and natural disasters can further exacerbate these issues, leading to supply chain bottlenecks and increased prices.

Another aspect influencing battery prices is the level of government support and incentives for the EV industry. Many governments worldwide have implemented policies to promote the adoption of electric vehicles, including tax credits, subsidies, and infrastructure development. These incentives can significantly reduce the effective cost of EVs for consumers, making them more competitive in the market. However, changes in government policies or the phase-out of incentives can lead to fluctuations in battery prices, as manufacturers may adjust their production strategies accordingly.

The impact of these price fluctuations on the EV market is substantial. When battery prices are low, it encourages more manufacturers to enter the market, leading to increased competition and a wider range of EV models. This, in turn, benefits consumers with more options and potentially lower prices. Conversely, during periods of high battery costs, the market may witness a slowdown in EV sales as consumers become more price-sensitive. This dynamic can influence the overall growth and sustainability of the EV industry.

In summary, the EV market's relationship with battery prices is intricate and influential. Fluctuations in battery costs, driven by technological advancements, supply chain factors, and government policies, directly impact the affordability and competitiveness of electric vehicles. Understanding these market trends is essential for stakeholders, including manufacturers, investors, and policymakers, to make informed decisions and contribute to the long-term growth of the EV industry.

Electric Revolution: Unlocking the Future of Sustainable Mobility

You may want to see also

Frequently asked questions

The cost of an EV battery can vary significantly and is influenced by several factors. Firstly, the battery capacity, measured in kilowatt-hours (kWh), directly impacts the price. Higher capacity batteries can store more energy, allowing for longer driving ranges, but they are generally more expensive. The type of battery technology also plays a role; lithium-ion batteries are common and relatively affordable, while other advanced chemistries like solid-state batteries might be pricier. Additionally, the brand and manufacturer's reputation can affect pricing, as some brands offer premium batteries with higher performance and longer warranties.

Battery replacement costs can vary widely depending on the make and model of the EV, as well as the age and condition of the battery. On average, a new EV battery can range from $500 to $15,000 or more. For instance, replacing a battery in a compact EV might cost around $3,000 to $5,000, while luxury vehicles or those with larger battery packs could exceed $10,000. It's important to note that some EV manufacturers offer battery replacement programs or extended warranties, which can provide financial relief for battery-related expenses.

Yes, many governments worldwide offer incentives and subsidies to promote the adoption of electric vehicles and reduce the overall cost for consumers. These incentives can include tax credits, rebates, or grants that directly apply to the purchase or installation of EV batteries. For example, some countries provide tax breaks for EV buyers, reducing the upfront cost. Additionally, governments may offer subsidies for battery research and development, which can indirectly lower battery prices over time. It's advisable to check with local authorities or EV associations to learn about available incentives in your region.

Resale value recovery for EV batteries is a topic of interest, and while it varies, some studies suggest that battery degradation is slower than initially thought. This means that even after a few years, an EV battery might retain a significant portion of its original capacity, translating to a higher resale value. However, the exact recovery amount depends on various factors, including the vehicle's overall condition, market demand, and the specific battery technology. It's recommended to research the resale trends for your EV model to estimate potential value retention.