Electric vehicles (EVs) have revolutionized the automotive industry, offering a sustainable and efficient mode of transportation. One intriguing aspect of EVs is their absence of traditional alternators, which are commonly found in internal combustion engine (ICE) vehicles. The primary reason for this design choice lies in the fundamental differences between the two power sources. EVs rely on electric motors and batteries, where the alternator's role in ICE vehicles is to generate electricity to charge the battery while the engine is running. In contrast, EVs draw power directly from their batteries, eliminating the need for an alternator. This design not only simplifies the EV's electrical system but also contributes to its overall efficiency and performance, making it a key factor in the growing popularity of electric mobility.

What You'll Learn

- Efficiency: Electric vehicles (EVs) use regenerative braking to charge batteries, eliminating the need for alternators

- Weight: Alternators are heavy, and EVs prioritize lightweight design for efficiency and range

- Complexity: EVs use simpler, more efficient power electronics, reducing the need for alternators

- Maintenance: EVs have fewer moving parts, leading to less maintenance and longer lifespans

- Cost: Alternators are expensive, and EVs aim for cost-effectiveness, making alternators redundant

Efficiency: Electric vehicles (EVs) use regenerative braking to charge batteries, eliminating the need for alternators

Electric vehicles (EVs) have revolutionized the automotive industry by offering an eco-friendly and efficient mode of transportation. One of the key factors contributing to their success is the absence of traditional alternators, which are commonly found in internal combustion engine (ICE) vehicles. The question of why EVs don't require alternators often sparks curiosity among enthusiasts and potential buyers alike.

The primary reason lies in the unique power management system of electric cars. EVs utilize a different approach to charging their batteries compared to conventional vehicles. Instead of relying on alternators, which generate electricity by converting mechanical energy into electrical energy, EVs employ regenerative braking technology. This innovative feature allows the vehicle to recover and store energy that would otherwise be lost during braking. When the driver applies the brakes, the electric motor reverses, acting as a generator, converting the kinetic energy back into electrical energy, which is then stored in the battery pack. This process significantly enhances the overall efficiency of the vehicle.

Regenerative braking offers several advantages over traditional alternators. Firstly, it reduces the energy loss associated with conventional braking systems, where kinetic energy is dissipated as heat. By capturing and reusing this energy, EVs can extend their range, making them more practical for everyday use. Secondly, the absence of alternators simplifies the vehicle's mechanical components, leading to lower maintenance requirements and increased reliability. With fewer moving parts, the risk of wear and tear is minimized, resulting in cost savings for owners in the long run.

The efficiency gains from eliminating alternators are substantial. EVs can achieve higher energy conversion rates, ensuring that a larger portion of the energy generated during driving is utilized effectively. This efficiency is further enhanced by the direct connection between the motor and the wheels, eliminating the need for a separate transmission, which is common in ICE vehicles. As a result, EVs can accelerate and decelerate more smoothly, providing a seamless driving experience.

In summary, the absence of alternators in electric vehicles is a design choice that significantly contributes to their overall efficiency and performance. By utilizing regenerative braking, EVs can capture and reuse energy, reducing energy loss and extending their range. This innovation, coupled with simplified mechanical systems, makes electric cars a more sustainable and practical transportation option, attracting environmentally conscious consumers and those seeking efficient and reliable vehicles.

Unlock EV Savings: Your Guide to Electric Vehicle Tax Credits

You may want to see also

Weight: Alternators are heavy, and EVs prioritize lightweight design for efficiency and range

The absence of alternators in electric vehicles (EVs) is a design choice that significantly contributes to their overall efficiency and range. One of the primary reasons for this decision is the weight of alternators. Alternators, which are used in traditional internal combustion engine (ICE) vehicles to charge the battery, are heavy components. In an EV, where every kilogram matters for efficiency and range, the weight of an alternator can be a significant drawback.

EV manufacturers have embraced lightweight design principles, aiming to minimize the weight of all vehicle components. This approach is crucial because a lighter vehicle has several advantages. Firstly, it improves the power-to-weight ratio, allowing the EV to accelerate more quickly and efficiently. Secondly, a lighter vehicle requires less energy to move, which translates to increased range. This is especially important for EVs, as range anxiety is a common concern among potential buyers.

The weight of an alternator is a critical factor in this context. Alternators typically weigh around 15-20 kilograms, and in some cases, even more. This weight adds to the overall mass of the vehicle, reducing its efficiency and potentially decreasing the range. For instance, a 20-kilogram alternator would contribute to the vehicle's weight, making it heavier and less efficient. This is a significant trade-off, especially when compared to the benefits of having an alternator, which are not as crucial in an EV's operation.

Furthermore, the design of EVs often incorporates advanced battery management systems that optimize charging and discharging. These systems can efficiently manage the battery's state of charge without the need for an alternator. As a result, the absence of an alternator contributes to a more streamlined and lightweight design, which is essential for the overall performance and appeal of electric vehicles.

In summary, the weight of alternators is a compelling reason for their absence in EVs. By prioritizing lightweight design, EV manufacturers can enhance efficiency, improve range, and provide a more responsive driving experience. This design choice aligns with the broader goal of making electric vehicles more accessible and appealing to a wider audience.

California's EV Future: The Post-Incentive Era

You may want to see also

Complexity: EVs use simpler, more efficient power electronics, reducing the need for alternators

Electric vehicles (EVs) have revolutionized the automotive industry, offering a cleaner and more sustainable mode of transportation. One of the key differences between EVs and traditional internal combustion engine (ICE) vehicles is the absence of alternators. This might seem counterintuitive, as alternators are essential components in ICE cars to generate electricity for charging the battery and powering the electrical systems. However, the design of EVs has led to a simplification of these systems, and the use of more efficient power electronics is a significant factor in this transformation.

In conventional vehicles, the alternator is responsible for converting mechanical energy from the engine into electrical energy to charge the battery and power accessories. This process involves a series of complex mechanical and electrical components. However, EVs operate on a different principle. Instead of relying on an alternator, they utilize a more straightforward and efficient approach.

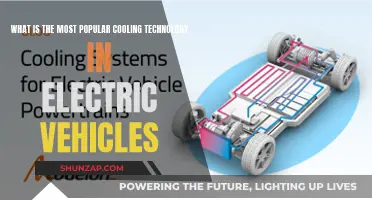

The power electronics in EVs are designed to be highly efficient and compact. These systems include devices like inverters, converters, and DC-DC converters, which manage the flow of electricity between the battery, motor, and other electrical components. One of the primary advantages of this design is that it eliminates the need for an alternator. EVs can directly draw power from the battery to supply the motor and accessories, ensuring a more efficient energy transfer. This simplification not only reduces the weight and size of the vehicle but also improves overall performance and range.

The absence of an alternator in EVs is a result of the vehicle's architecture, which prioritizes efficiency and simplicity. By using advanced power electronics, EVs can achieve a higher state of energy management. This technology allows for precise control of power distribution, ensuring that the battery is charged optimally and that the motor receives the required power for acceleration and operation. Moreover, the efficient power management system in EVs helps to minimize energy losses, making the overall driving experience more responsive and environmentally friendly.

In summary, the lack of alternators in electric vehicles is a strategic design choice. The use of simpler and more efficient power electronics has allowed EV manufacturers to create vehicles that are lighter, more compact, and more environmentally conscious. This innovation in power management has played a crucial role in the success and widespread adoption of electric mobility, offering a promising future for sustainable transportation.

Electric Fleet Incentives: Unlocking Corporate Tax Benefits for Green Transportation

You may want to see also

Maintenance: EVs have fewer moving parts, leading to less maintenance and longer lifespans

Electric vehicles (EVs) have revolutionized the automotive industry, offering a more sustainable and efficient mode of transportation. One of the key differences that set EVs apart from traditional internal combustion engine (ICE) vehicles is their power generation and charging system. Unlike ICE vehicles, which rely on alternators to generate electricity and charge the battery, EVs utilize a different approach that significantly reduces the need for frequent maintenance.

The primary reason EVs don't require alternators is the absence of an internal combustion engine. In ICE vehicles, the alternator is a crucial component that generates electricity to charge the battery and power the electrical systems. However, in EVs, the primary power source is the battery, which is charged through regenerative braking and external charging methods. This shift in power generation means that EVs have a simpler electrical architecture, often featuring a direct current (DC) to DC converter or an inverter, which manages the flow of electricity between the battery and the vehicle's systems.

The reduced complexity of EV electrical systems directly translates to lower maintenance requirements. With fewer moving parts and a more streamlined design, EVs experience less wear and tear compared to ICE vehicles. Traditional alternators, which are prone to failure due to their mechanical nature, are no longer a concern for EV owners. The absence of an alternator eliminates the risk of belt-driven issues, such as belt slippage or wear, which can lead to costly repairs and replacements in ICE vehicles.

Furthermore, the maintenance schedule for EVs is generally less frequent and less intensive. Most EVs require less frequent oil changes, as there is no engine oil to change. This not only reduces the environmental impact but also saves vehicle owners time and money on maintenance. The simplified electrical system also means that EV owners can expect fewer trips to the mechanic for electrical component repairs.

The longevity of EVs is another advantage that stems from their maintenance-friendly design. With fewer moving parts and less complex systems, EVs are built to last. The absence of an alternator, which is a common failure point in ICE vehicles, contributes to the overall reliability and extended lifespan of EVs. This not only benefits the environment but also provides long-term cost savings for vehicle owners.

Unleash the Power: Top Hybrid Speeds in Electric Mode

You may want to see also

Cost: Alternators are expensive, and EVs aim for cost-effectiveness, making alternators redundant

The absence of alternators in electric vehicles (EVs) is a strategic design choice that significantly contributes to their overall cost-effectiveness and efficiency. One of the primary reasons for this decision is the high cost associated with alternators. Alternators, which are used in conventional internal combustion engine (ICE) vehicles to charge the battery and power the electrical systems, are mechanical devices that convert mechanical energy into electrical energy. However, these components are relatively expensive to manufacture and maintain, especially when compared to the simpler and more compact electrical systems found in EVs.

In traditional cars, alternators are essential to keep the battery charged and provide power to various electrical components, such as lights, radio, and accessories. However, in EVs, the reliance on a single, powerful battery pack for energy storage and supply means that the need for an alternator is significantly reduced. The battery in an EV is designed to store a large amount of energy, and its charging is primarily managed by the vehicle's onboard charger, which is more efficient and less complex than a traditional alternator system.

The cost-effectiveness of EVs is a critical factor in their market appeal. By eliminating the need for an alternator, manufacturers can streamline the production process, reduce material costs, and simplify the overall vehicle architecture. This simplification leads to lower production costs, which can be passed on to consumers in the form of more affordable vehicles. Additionally, the absence of an alternator contributes to the overall weight reduction of the vehicle, further enhancing its efficiency and performance.

Furthermore, the design of EVs often incorporates regenerative braking systems, which capture and store energy that would otherwise be lost during braking. This energy recovery system further reduces the strain on the battery and the need for an alternator to recharge it. As a result, the combination of efficient battery management, regenerative braking, and the absence of an alternator contributes to the overall cost savings and improved performance of electric vehicles.

In summary, the high cost of alternators and the focus on cost-effectiveness in EV design have led to their omission from these vehicles. The efficient battery systems and regenerative braking technologies in EVs ensure that the lack of an alternator does not compromise the vehicle's performance or functionality, making it a strategic and economically sound decision in the evolution of sustainable transportation.

Power Up: The Ultimate Guide to Refueling Your Electric Vehicle

You may want to see also

Frequently asked questions

Electric vehicles primarily rely on battery packs as their main power source, and alternators are not necessary in this setup. Alternators are used in traditional internal combustion engine (ICE) vehicles to recharge the battery while the car is in motion. However, EVs use advanced battery management systems that can efficiently store and distribute energy, eliminating the need for an alternator.

EVs charge their batteries through an external power source, typically a charging station or a wall-mounted charger. These chargers connect to the vehicle's onboard charging system, which includes a charging port and a power electronics module. The charging process involves converting the alternating current (AC) from the power source to direct current (DC) to recharge the battery.

In conventional cars with internal combustion engines, the alternator serves as a generator, producing electricity to power the vehicle's accessories and recharge the battery. As the engine runs, the alternator uses the mechanical energy from the engine to generate electrical power, ensuring the battery stays charged and the car's electrical systems function properly.

While EVs don't use alternators, they still require electrical generation to power certain components. Some EVs employ regenerative braking systems that convert kinetic energy back into electrical energy, which can be stored in the battery. Additionally, EVs may have auxiliary batteries or power supplies for specific functions, but these are separate from the main battery and charging system.

Yes, eliminating the alternator offers several benefits. Firstly, it reduces the overall weight of the vehicle, as alternators can be heavy. Secondly, it simplifies the drivetrain and electrical system, making maintenance easier. Without the need for an alternator, EVs can also have more efficient and compact designs, contributing to their overall performance and range.